Method for preparing transparent calcium fluoride ceramics

A calcium fluoride and transparent technology, which is applied in the field of non-oxide transparent ceramic preparation, can solve problems such as carburizing pollution, inability to remove carbon by heat treatment, and non-oxide transparent ceramics are easy to be oxidized, so as to improve light transmittance and eliminate carbon pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

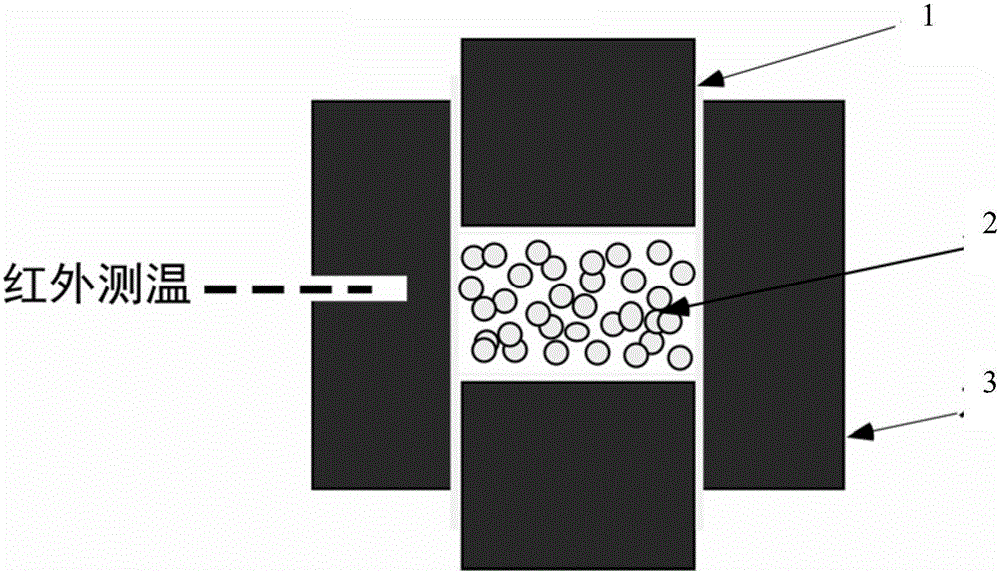

[0023] 1) Sample loading of powder raw materials: such as figure 2 , first wrap the inner wall of the graphite mold with metal molybdenum foil 1 with a thickness of 0.025mm, then put calcium fluoride powder 2 into the graphite mold 3, and wrap the outer wall of the mold with carbon felt for heat insulation;

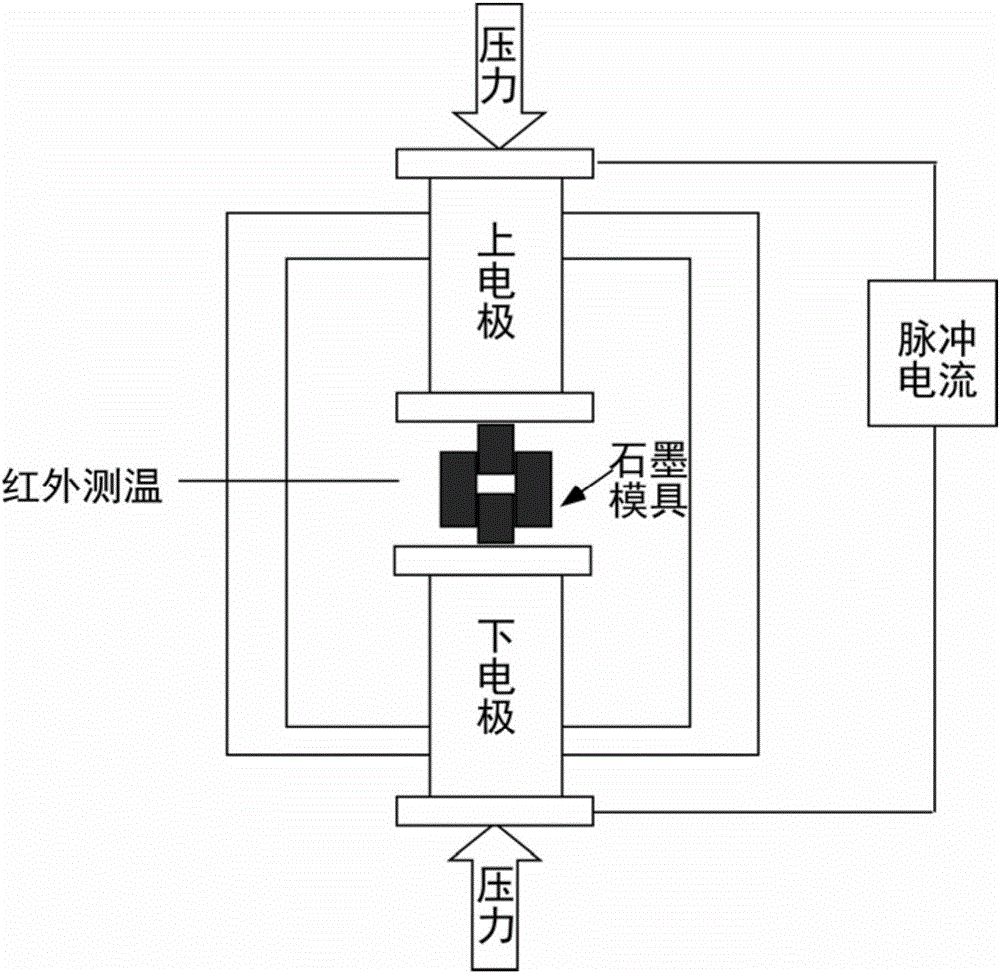

[0024] 2) Sintering of transparent ceramics: put the graphite mold in such as figure 1 In the discharge plasma sintering furnace shown, vacuumize to 20Pa, heat up to 1100°C at 100°C / min, pressurize at 100MPa, and hold for 10min;

[0025] 3) Sample treatment: After the sample is naturally cooled, the sample is taken out, rough-ground with different types of sandpaper, and then polished on both sides with diamond polishing liquid on an automatic polishing machine to obtain a transparent calcium fluoride ceramic with a thickness of 1mm.

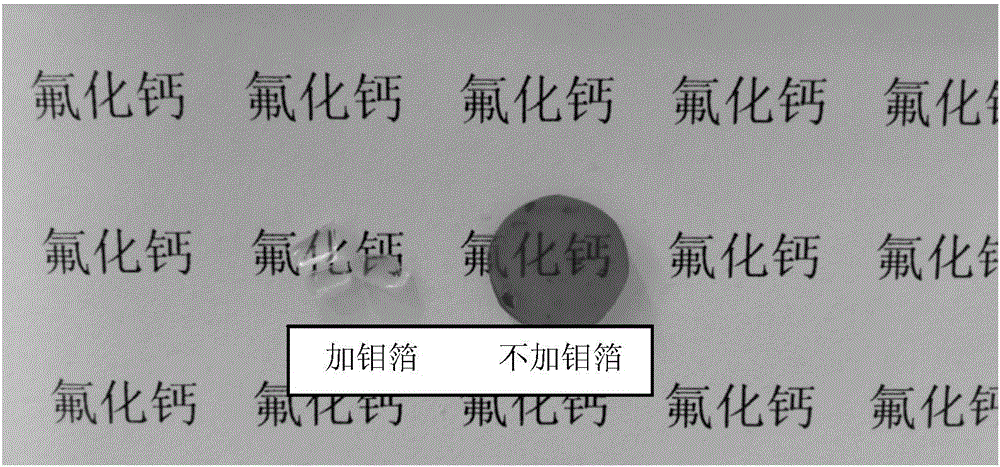

[0026] Such as image 3 The calcium fluoride transparent ceramic prepared by adding molybdenum foil is pure and transparent, and the wo...

Embodiment 2

[0028]1) Sample loading of powder raw materials: first wrap the inner wall of the graphite mold with metal nickel foil with a thickness of 0.025mm, then put the calcium fluoride powder into the graphite mold, and wrap the outer wall of the mold with carbon felt for heat insulation;

[0029] 2) Sintering of transparent ceramics: put the graphite mold in a discharge plasma sintering furnace, evacuate to 20Pa, heat up to 1100°C at 100°C / min, pressurize at 100MPa, and hold for 10min;

[0030] 3) Sample treatment: After the sample is naturally cooled, the sample is taken out, rough-ground with different types of sandpaper, and then polished on both sides with diamond polishing liquid on an automatic polishing machine to obtain transparent calcium fluoride ceramics.

Embodiment 3

[0032] 1) Powder raw material loading: first wrap the inner wall of the graphite mold with metal foil with a thickness of 0.025mm, then put the calcium fluoride powder into the graphite mold, and wrap the outer wall of the mold with carbon felt for heat insulation;

[0033] 2) Sintering of transparent ceramics: put the graphite mold in a discharge plasma sintering furnace, evacuate to 20Pa, heat up to 1200°C at 100°C / min, pressurize at 100MPa, and hold for 20min;

[0034] 3) Sample treatment: After the sample is naturally cooled, the sample is taken out, rough-ground with 600-grit sandpaper, and then polished on both sides with diamond polishing liquid on an automatic polishing machine to obtain transparent calcium fluoride ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com