Protective paint for heat treatment of metal

A technology of metal heat treatment and protective coating, applied in the direction of coating, etc., can solve the problem of single metal protection, achieve good drying performance, prevent oxidation, and prevent decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

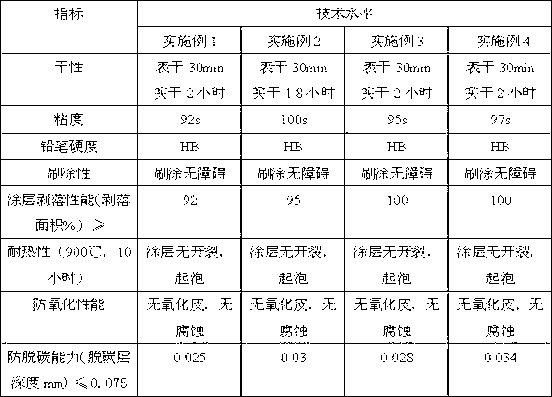

Examples

Embodiment 1

[0014] Army Green Metal Heat Treatment Protective Coating (Table 1)

[0015] Material name Category Material specification Weight (kg) Ethyl cellulose resin W type 3 Organic Bentonite Clay 20% 5 Chrome Oxide Green industry 8 11# glass frit industry 12 04# glass frit industry 10 M-1 glass frit industry 8 barium metaborate industry 6 Mica powder 400 mesh 2 Red mica iron oxide 100 mesh 5 ethanol industry 40

[0016] Wherein the organic bentonite paste (20%) in Table 1 is composed of organic bentonite 20% of organic bentonite, 5% ethanol, and 75% xylene; by weight percentage. Chromium oxide green is a pigment for industrial products.

[0017] The preparation process of the coating: the above-mentioned ethyl cellulose resin, organic bentonite paste, chromium oxide green, 11# glass frit, 04# glass frit, M-1 glass frit, mica powder, barium metaborate, red mica iron oxide , ethanol is adde...

Embodiment 2

[0019] Protective coatings for heat treatment of ferrous metals (Table 2)

[0020] Material name Category Material specification Weight (kg) Ethyl cellulose resin W type 4 Organic Bentonite Clay 20% 6 Chrome black industry 3 11# glass frit industry 14 04# glass frit industry 11 M-1 glass frit industry 12 barium metaborate industry 8 Mica powder 400 mesh 3 Red mica iron oxide 100 mesh 6 ethanol industry 34

[0021] Wherein the organic bentonite paste in table 2, its concentration is 20%, and composition is with embodiment 1; Its coating preparation method is identical with embodiment 1. Iron chrome black is a pigment for industrial products.

Embodiment 3

[0023] Gray Metallic Heat Treatment Protective Coatings (Table 3)

[0024] Material name Category Material specification Weight (kg) Ethyl cellulose resin W type 4 Organic Bentonite Clay 20% 6 Titanium dioxide Rutile type 8 Chrome black industry 1 11# glass frit industry 14 04# glass frit industry 10 M-1 glass frit industry 10 barium metaborate industry 5 Mica powder 400 mesh 3 Red mica iron oxide 100 mesh 7 ethanol industry 34

[0025] Wherein the organic bentonite paste in table 3, its concentration is 20%, and composition is with embodiment 1; The preparation method of its coating is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com