Acid Washing-free and drawing-free apparatus for steel strand

The invention relates to a drawing device and a technology for steel strands, which are applied to the field of pickling-free drawing devices for steel strands, and can solve the problems of high production cost, multiple environmental protection investments, and large fuel consumption, so as to protect the environment, improve labor productivity, and reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

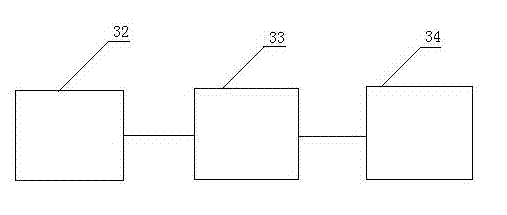

[0015] figure 1 As shown, the present invention is provided with frame, and on the frame end-to-end are installed steel wire rod peeling machine 32, steel strand acid-free wire drawing dust remover 33 and steel strand wire drawing online phosphating and saponification device 34.

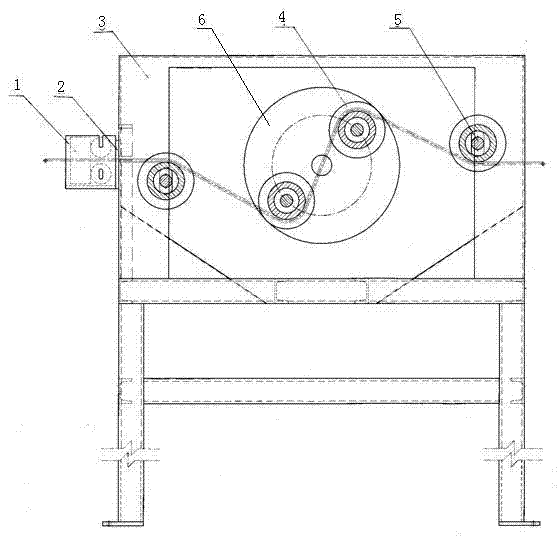

[0016] figure 2 Shelling case 3 is installed above the frame of steel wire rod peeling machine 32 of the present invention as shown, and one end of shelling case 3 is fixed with guide box 2, and guide die 1 is inserted in guide box 2, peels A peeling pulley 4 is respectively fixed on the two ends of the box 3 through the rotating shaft. A turntable 6 is installed through the mandrel 5 in the shelling box 3. Two stripping pulleys 4 are fixed on the radial direction of the turntable 6 through the rotating shaft. Two lines are processed on the peeling pulley 4. Groove, mandrel 5 afterbody is provided with nut and adjusting block place, shelling case 3 lower ends are provided with chip discharge port, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com