Nitrogen-strengthened TiZrHfNb-based high-entropy alloy and preparation method thereof

A technology of high-entropy alloys and alloys, applied in the field of metal materials and their preparation, to achieve the effects of convenient preparation, no work hardening, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

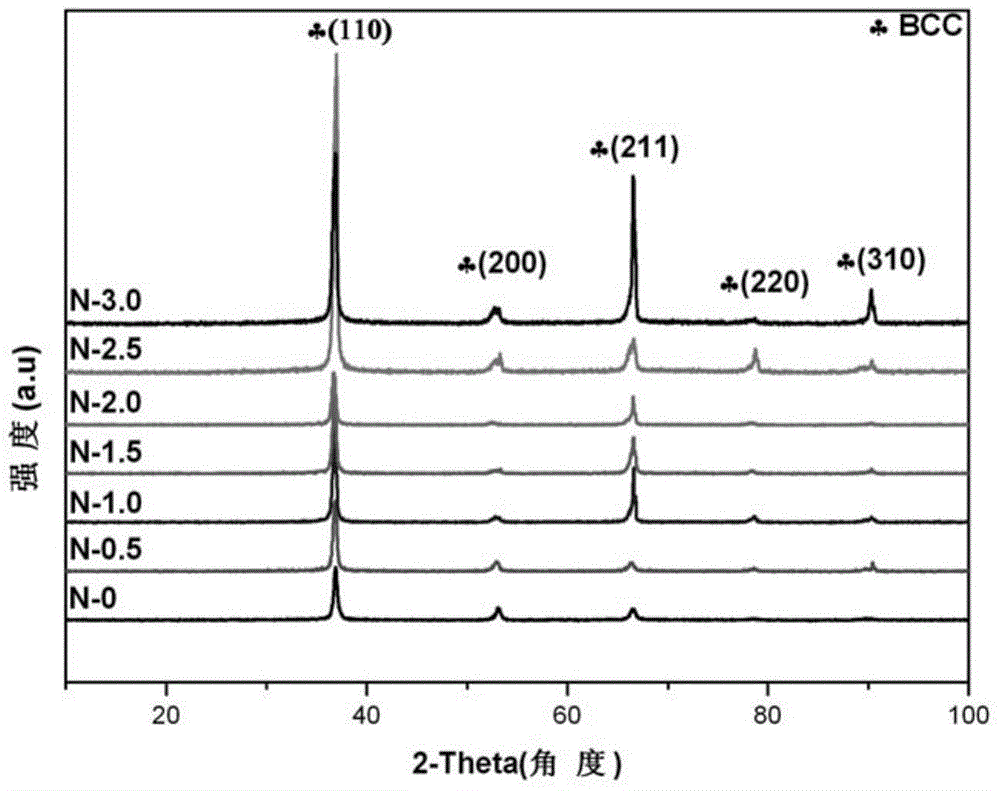

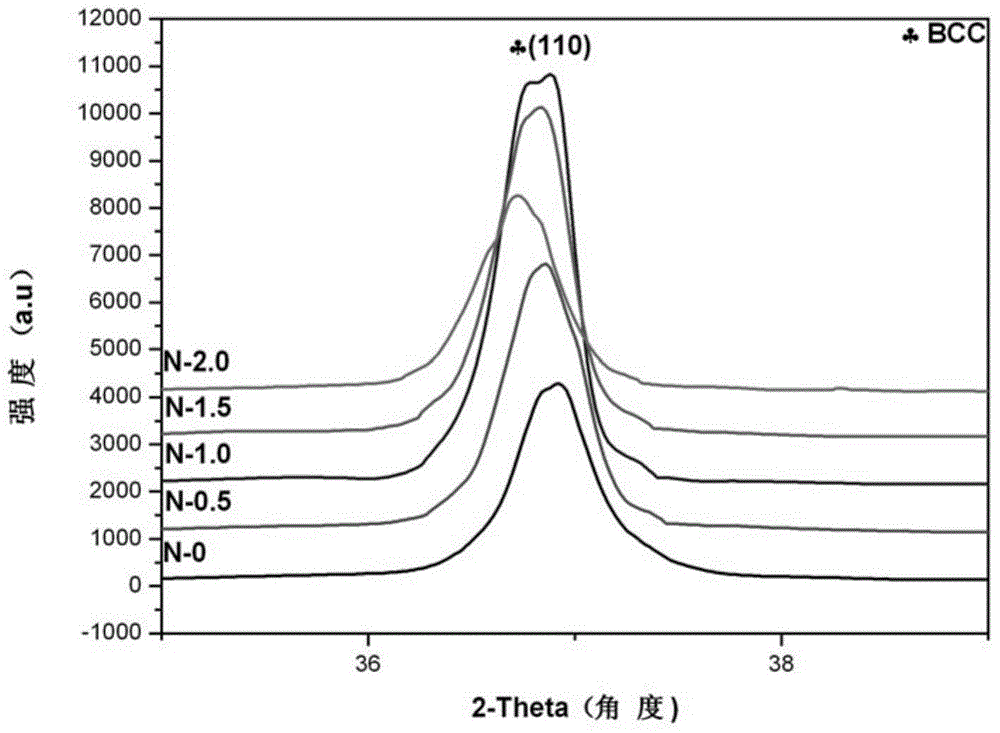

[0036] The preparation process of TiZrHfNbN high entropy alloy is as follows:

[0037] (1) Raw material preparation: The alloy smelting raw materials used in the present invention are high-purity (≥99.9%) Ti, Zr, Hf and Nb elements, and the raw materials are removed by means of grinding wheels, etc., and the scale is accurately weighed and proportioned according to the molar ratio , cleaned with ultrasonic vibration in alcohol, used for co-smelting alloys, and N element is directly added in the form of powder or bulk TiN. The sources of Ti elements include high-purity Ti and TiN, and the total content of Ti elements conforms to the nominal composition.

[0038] Table 1 Nominal composition (at%) of TiZrHfNbN high-entropy alloy system

[0039] alloy Ti Zr f Nb N TiZrHfNb 25 25 25 25 - (TiZrHfNb) 99.5 N 0.5 24.875 24.875 24.875 24.875 0.5 (TiZrHfNb) 99 N 1.0 24.75 24.75 24.75 24.75 1.0 (TiZrHfNb) 98.5 N 1.5 24.625 2...

Embodiment 2

[0058] (TiZrHfNb) 94 m 5 N 1.0 Preparation and properties of (M=Al, Ta, V)

[0059] In the alloy system provided by the present invention, the doping of other alloy elements will significantly change the mechanical properties of the alloy. Figure 7 It is the XRD pattern of TiZrHfNb-based high-entropy alloys added with three different alloying elements when the nitrogen content is 1 at%. 1, 2, 3, 4 respectively correspond to (TiZrHfNb) 99 N 1.0 , (TiZrHfNb) 94 al 5 N 1.0 , (TiZrHfNb) 94 Ta 5 N 1.0 , (TiZrHfNb) 94 V 5 N 1.0 alloy. Among them, the abscissa is the 2θ angle, and the ordinate is the diffraction intensity (arbitrary unit). Contrast (TiZrHfNb) 99 N 1.0 According to the XRD pattern of the alloy, it can be found that the addition of 5 at% Al, Ta, V did not change the single-phase BCC structure of the alloy. At the same time, we found that the addition of Al, Ta, and V significantly increased the intensity of the first diffraction peak, that is, signif...

Embodiment 3

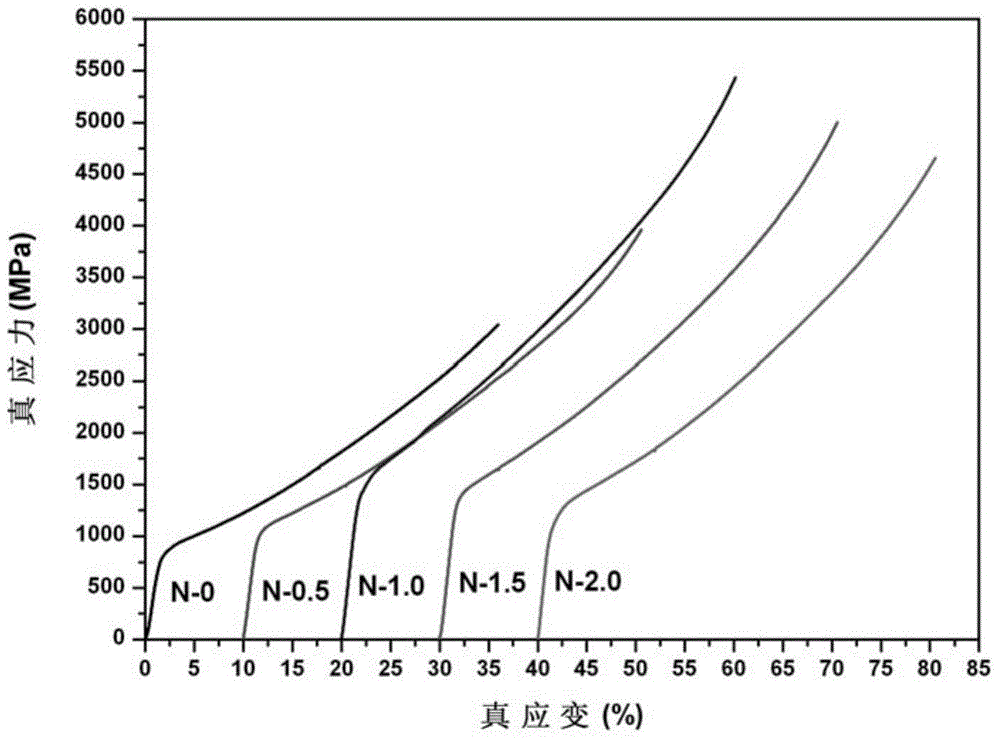

[0061] Part of the alloy composition and performance list studied by the present invention

[0062] Various ratios of nitrogen-strengthened TiZrHfNb-based high-entropy alloys were prepared according to the methods of Examples 1 and 2, and their compositions and mechanical properties are listed in Table 3.

[0063] Table 3 Part of the alloy composition, tensile yield strength σy and tensile plasticity εp studied in the present invention

[0064] Example Alloy composition (at %) σ y (MPa) ε p (MPa) 1 (TiZrHfNb) 99.5 N 0.5 899 19.4 2 (TiZrHfNb) 99 N 1.0 1051 17.8 3 (TiZrHfNb) 98.5 N 1.5 1119 13.2 4 (TiZrHfNb) 98 N 2.0 1282 10.7 5 (TiZrHfNb) 97.5 N 2.5 1379 1 6 (TiZrHfNb) 97 N 3.0 - 0 7 (TiZrHfNb) 96 N 4.0 - - 8 (TiZrHfNb) 95 N 5.0 - - 9 Ti 35 Zr 15 Hf 20 Nb 28 N 0.5 1060 20.5 10 Ti 15 Zr 35 Hf 20 Nb 27.5 N 0.5 1120 18.6 11 Ti 10 Zr 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com