Novel process for on-line removing of scale at surface of hot-rolled copper plate belt

A technology of oxide skin and new technology, which is applied in the direction of workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., to achieve the effect of improving comprehensive yield, reducing raw material consumption, and strong equipment practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

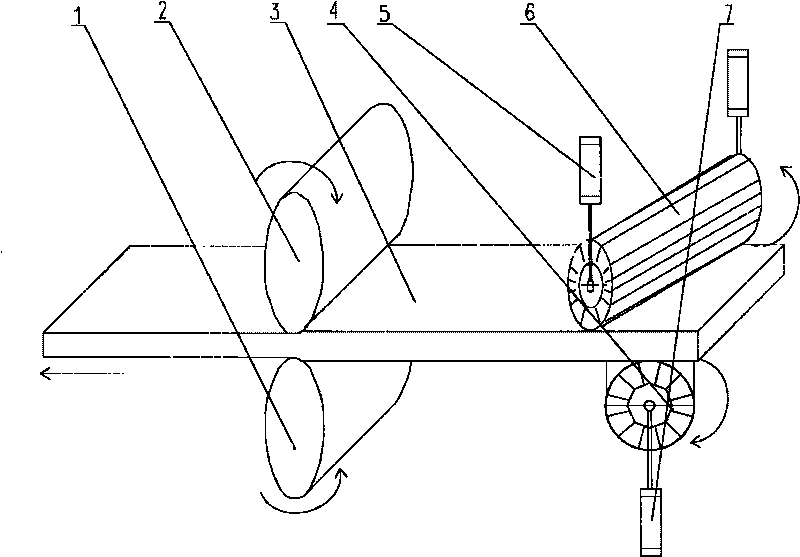

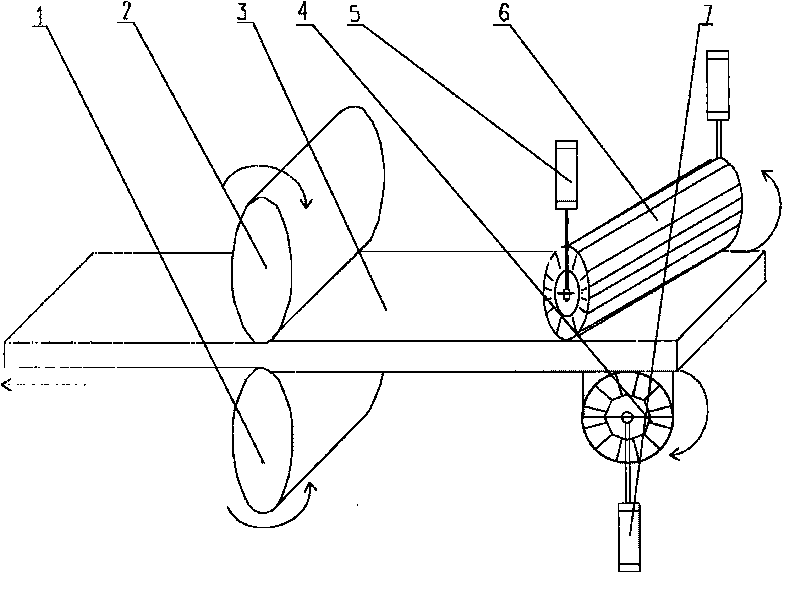

[0027] Such as figure 1 Shown: A new process for removing the scale on the surface of hot-rolled copper strips on-line is a process of scraping and purging the scale on the surface of the billet during hot rolling. The steps are as follows:

[0028] 1) Use scraping rollers 4 and 6 on the inlet and outlet sides of the work rolls to scrape the oxide skin on the upper or lower surface of the rolled piece 3 to scrape off the oxide skin that has been lifted and loosened by hot rolling , so as not to be pressed into the inside of the rolled piece during the next rolling pass;

[0029] 2) For the installation of the scraping rollers 4 and 6, the axis position should be at an angle less than or greater than 90° with the center line of the rolled piece; When the piece is being rolled to the left, when the scraping rollers 4 and 6, which are pressing on the surface of the rolled piece, rotate at a high speed, the scale can be thrown to one side of the rolled piece, so that the subseque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com