Metal molten drop ejecting device and method for ejecting high-melting-point metal molten drops using same

A technology of spraying device and molten metal, which is applied in the field of spraying high-melting-point metal droplet and high-melting-point metal droplet spraying device, which can solve the problems of poor stability and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

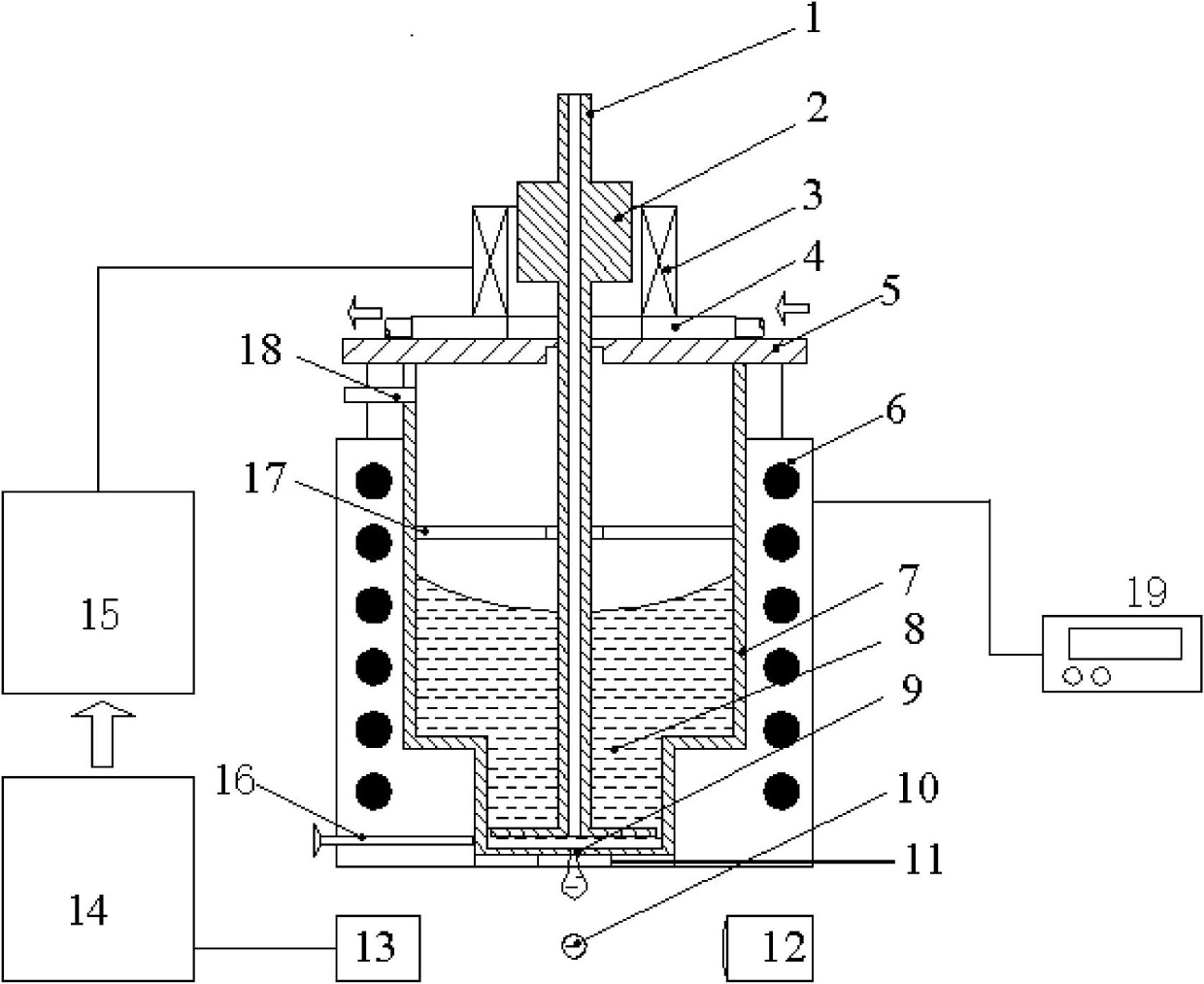

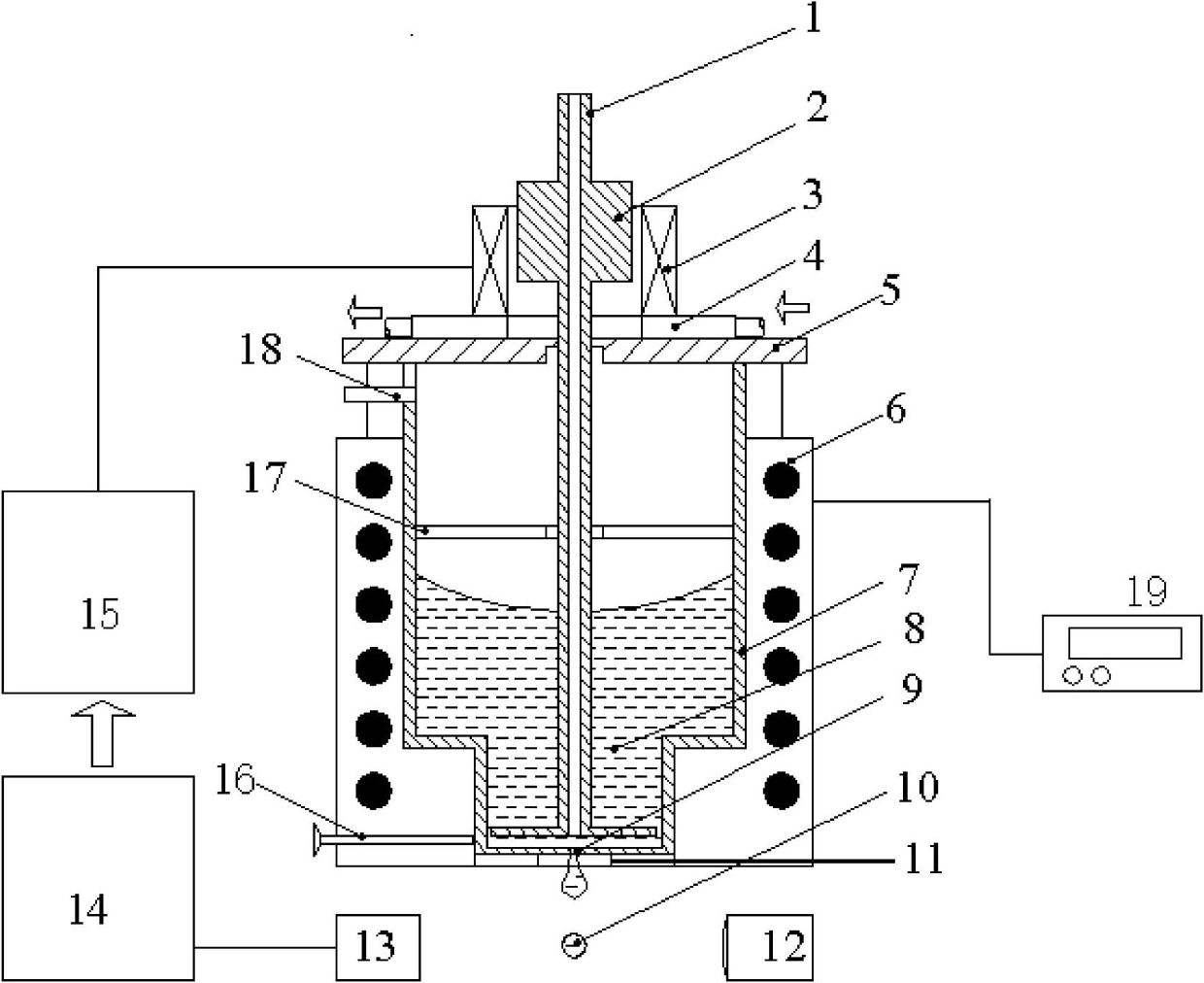

[0025] refer to figure 1 , the metal droplet ejection device of the present invention includes a heater 6, a crucible 7, a nozzle 9, an induction block 2, a cooling block 4, an exciting rod 1, an electromagnetic coil 3, a heat shield 5, a laser 12, a photoelectric sensor 13, a photoelectric The signal processing unit 14, the excitation driver 15, the thermocouple 16, the filter plate 17, and the excitation rod 1 pass through the cooling plate 4 from top to bottom, and a pressure inlet 18 is provided on the wall of the crucible 7 near the top, and the bottom of the crucible 7 passes through the high temperature A nozzle 9 is bonded with an adhesive, a heater 6 is installed on the outside of the crucible 7, and a thermocouple 16 is installed on the outside of the bottom of the crucible. After the temperature of the crucible is detected by the thermocouple 16, it is transmitted to the heating controller 19, and the heating controller 19 controls the temperature of the crucible a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com