Precision injection molding device and method for realizing rapid mold manufacturing by using the same

A spray forming and precise technology, applied in the field of rapid mold manufacturing, can solve the problems of large cutting volume, long production process, brittle steel, etc., and achieve the effects of low production cost, high production efficiency and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, the casting mold 8 adopts a ceramic type, and the waste mold is remanufactured.

[0035] Take HM1 die steel engine valve hot final forging die as an example.

[0036] 1) Make a ceramic mold. Firstly, according to the forming requirements of valve forgings, considering the characteristics of ceramic forming, design and process aluminum-based separated ceramic molds; secondly, prepare ceramic slurry with alumina ceramic powder and binder, and form ceramic molds in copy molds8 ; Then, solidify, dry and strengthen.

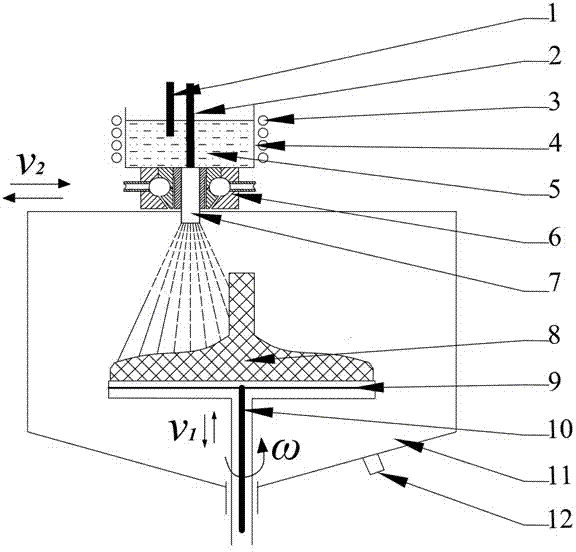

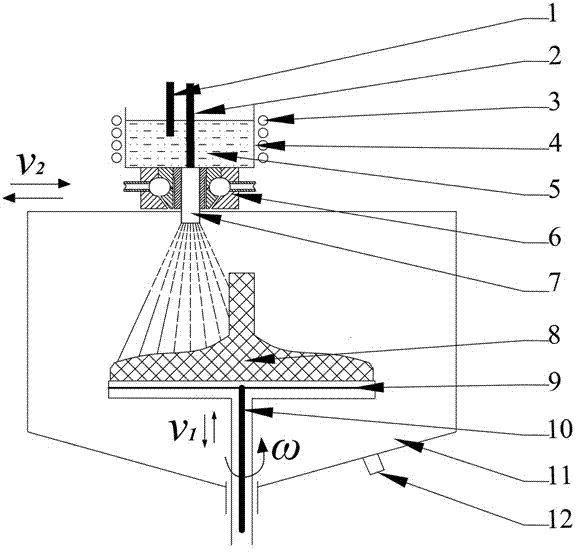

[0037] 2) Precision spray forming. Put the scrapped HM1 steel molds in the melting crucible 4 after cleaning scale, impurities and oil stains, use high-frequency induction power supply, and carry out melting under the gas protection atmosphere. Temperature measurement, temperature control, and auxiliary infrared thermometer for temperature measurement and calibration to accurately control the solution temperature; at the end of s...

Embodiment 2

[0041] In this embodiment, the casting mold 8 adopts a metal casting mold, and the waste mold is remanufactured.

[0042] 1) Make a metal mold. First of all, according to the forming requirements of the valve forgings, considering the shrinkage of the material, the valve steel 21-4N is directly cut to manufacture the casting mold. The mold surface roughness reaches 0.1μm.

[0043] 2) Precision spray forming. It is basically the same as Example 1, except that the superheating degree of the metal solution 5 is slightly higher, 100-200°C, and the preheating temperature of the mold 8 is also slightly higher, 700-800°C.

[0044] 3) Clean up. After cooling, the metal mold in the mold is extruded on a press to obtain a precision injection molding mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com