Dust-free corrosion-resistant coating process for steel materials

A coating process, a technology for steel materials, applied to devices for coating liquids on surfaces, coatings, pre-treatment surfaces, etc., can solve problems such as decreased anti-corrosion ability, substrate wave crest deformation, dust pollution, etc., and achieves fast processing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

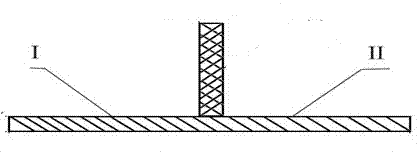

[0017] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0018] The invention provides a dust-free anti-corrosion coating process for iron and steel materials, the steps of which are:

[0019] Step 1. Clean the surface of the substrate to be coated with 2500bar high-pressure water generated by ultra-high pressure water jet equipment to remove rust, scale, and old paint on the surface of the substrate. This process can completely clean the metal base material to reach the Sa2.5 standard or above. Since the water contains oxygen and the metal surface is shot at ultra-high pressure, the atoms on the metal surface will be activated to oxidize it, and secondary floating rust will occur in a short time. As a result, the surface of the cleaned substrate produces floating rust after drying. Ultra-high pressure water jet equipment can be driven by diesel engine or electric drive.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com