Heavy metal sludge recycling and comprehensive utilization method

A heavy metal sludge and recycling technology, applied in the direction of improving process efficiency, etc., can solve the problems of no economic benefit, high cost of car manufacturing, secondary pollution, etc., and achieve significant economic benefits, low cost, resource saving and energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

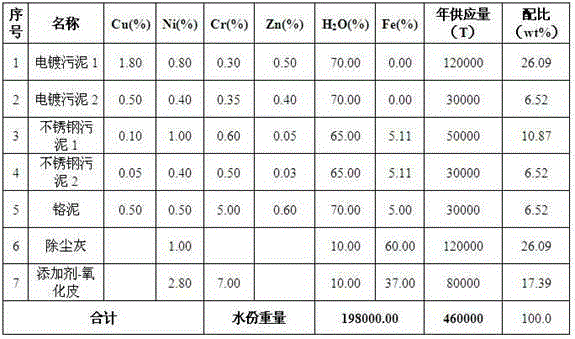

[0020] surface 1 The composition and proportion of each raw material

[0021]

[0022] (1) Mix stainless steel sludge 1, stainless steel sludge 2, electroplating sludge 1, electroplating sludge 2, chromium sludge, dust removal ash and oxide scale produced in the production process of Inconel alloy according to the mass ratio and add them to the ball making machine Medium pelletizing, preheating and drying the mixed pellets in a drying kiln (200°C);

[0023] (2) Add coal, coke, and limestone to the dried mixture, and carry out reduction roasting in a rotary kiln (1000 ℃) to obtain calcined sand; the flue gas generated by the rotary kiln is preheated and recovered by a waste heat boiler, and purified Discharge after reaching the standard, and return the collected smoke and dust to the raw material warehouse as dust for dust removal;

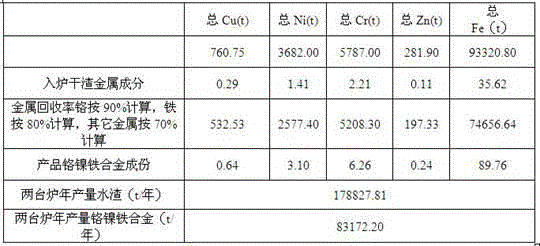

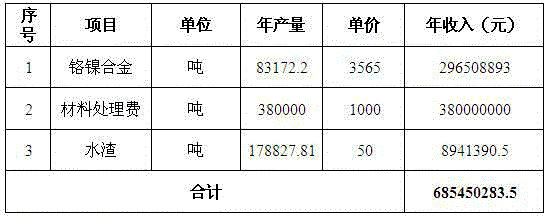

[0024] (3) Put the calcined sand into the submerged arc furnace (1600 ℃) for smelting, and cast the molten Inconel into ingots to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com