Limescale treatment method for steam heating type cooking appliance

A technology of cooking utensils and processing methods, which is applied in the directions of steam generation, lighting and heating equipment, control systems, etc., can solve the problems of burnout of heating devices, unexpected effects, and difficulty in cleaning scale, and achieves easy implementation and low detection cost. , the effect of accurate scale detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

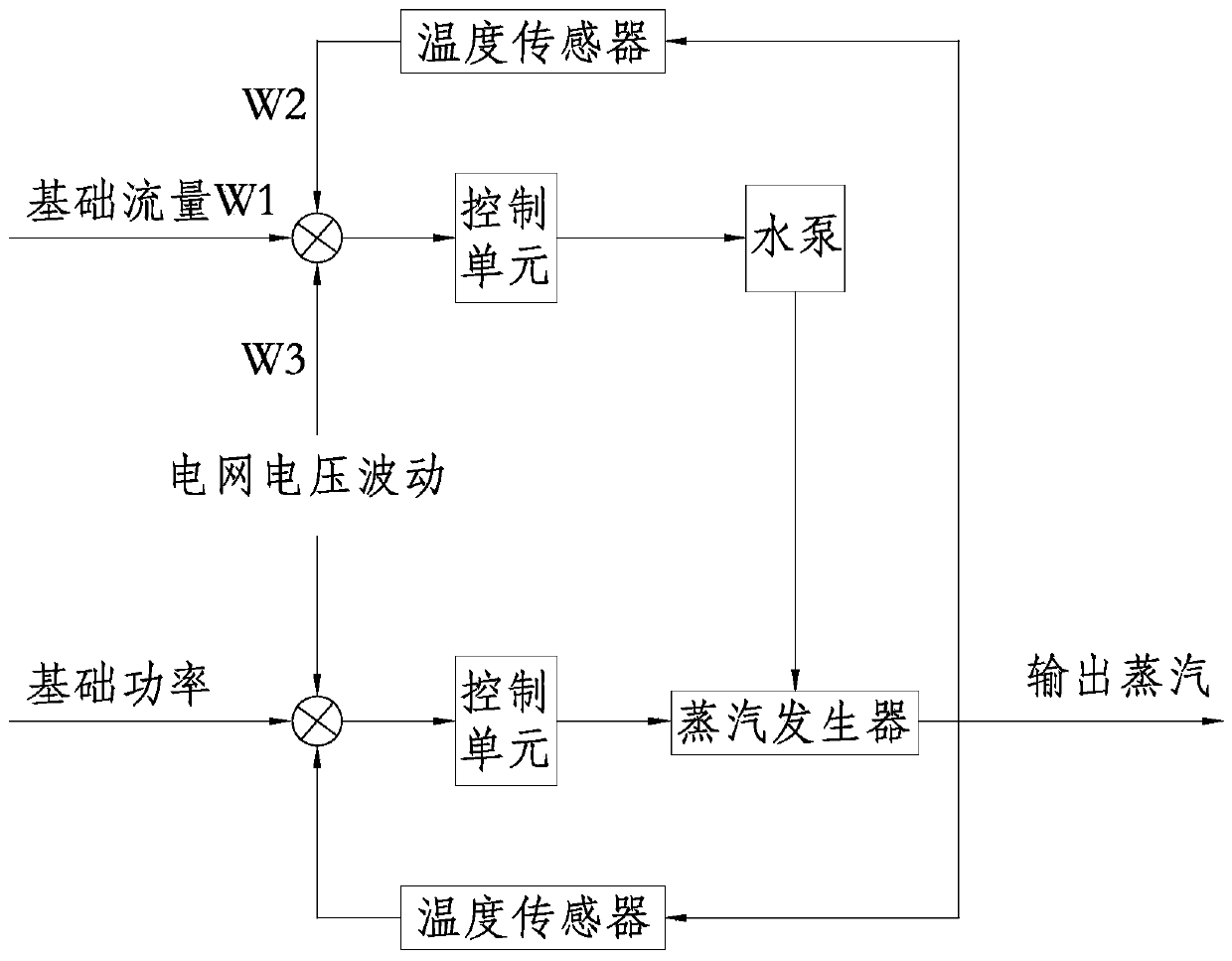

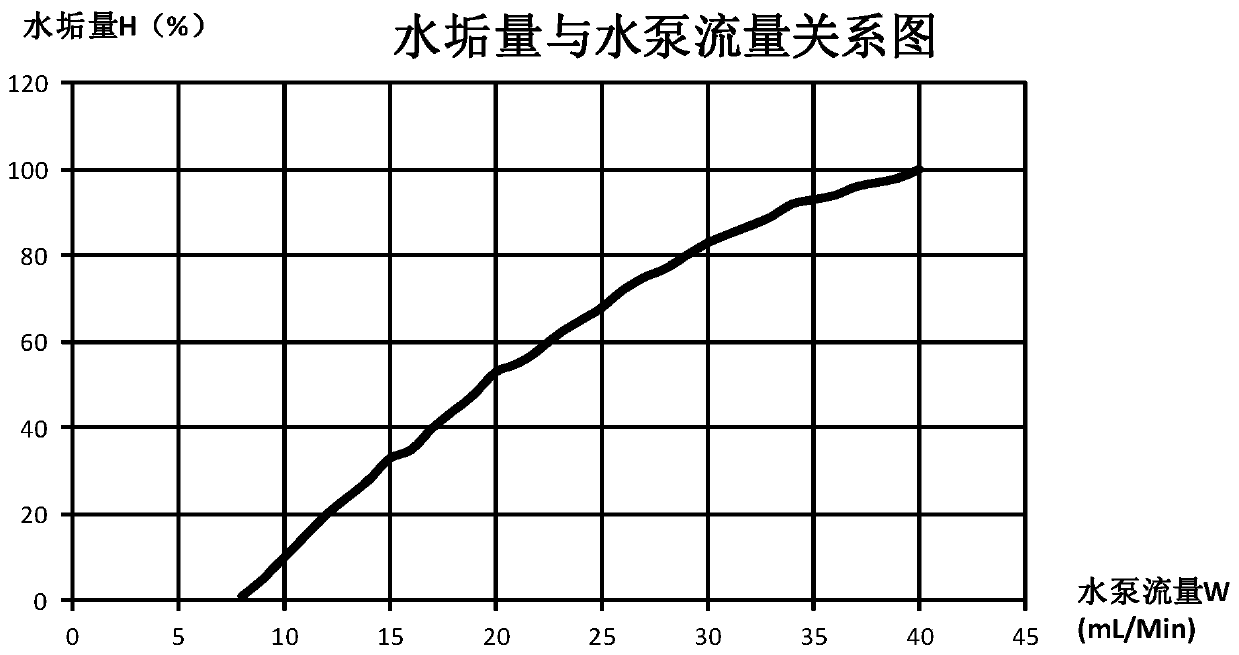

[0042] The present invention proposes a scale treatment method for a steam heating cooking appliance, the steam heating cooking appliance includes a steam generator for heating water to generate steam, a water pump for supplying water to the steam generator, and a water pump for detecting steam generation The scale treatment method includes the following steps: obtaining the current temperature of the steam generator; adjusting the flow rate of the water pump according to the current temperature of the steam generator; determining the corresponding amount of scale in the steam generator according to the adjusted flow rate of the water pump. The above scale treatment method is not affected by factors such as water quality in different regions and the frequency of use of cooking utensils, and the scale detection result is more accurate; compared with the method of detecting scale by weighing and adding sensors, the above scale treatment method relies on the steam generation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com