Deoxidation and organic sulfur hydro-conversion bifunctional catalyst, and preparation method and application thereof

A dual-function catalyst and hydrogenation conversion technology, which is applied in the field of gas purification, can solve the problems of destroying the activity of hydrogenation catalysts, easy poisoning of deoxidation catalysts, long purification process, etc., and achieves high organic sulfur hydrogenation conversion rate, simple preparation method, The effect of high deoxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

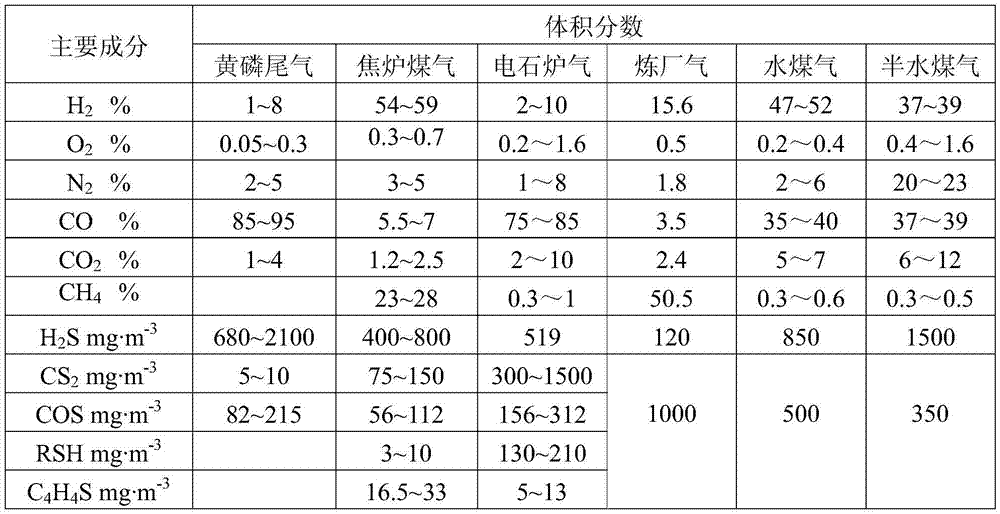

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Present embodiment catalyst comprises the component of following mass parts:

[0029] 1 part of active component, 20 parts of active auxiliary agent, and 79 parts of carrier, wherein the active ingredient is molybdenum and nickel, the active auxiliary agent is phosphorus, and the carrier is ZrO 2 The number of parts by mass is 5 parts, and the catalyst number of this embodiment is D-01.

[0030] The preparation method of present embodiment catalyst is as follows:

[0031] 1) 13.8gZr(NO 3 ) 4 ·5H 2 O is mixed with 74.5g of alumina powder, fully ground in a mortar for 2 hours, and then fired at 300°C for 24 hours to obtain ZrO 2 -Al 2 o 3 carrier;

[0032] 2) Add 0.6g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 1.9gNi(NO 3 ) 2. 6H 2 O and 37.2g (NH 4 ) 2 HPO4 Dissolve in 100g of water to make a mixture;

[0033] 3) Mix the carrier prepared in step 1) with the mixed solution in step 2), knead fully, press into a sheet with a diameter of 2mm, dry at 120°C for 2 hours, and...

Embodiment 2

[0035] Present embodiment catalyst comprises the component of following mass parts:

[0036] 50 parts of active components, 0.1 part of active auxiliary agent, 49.9 parts of carrier, wherein the active ingredient is molybdenum, nickel, iron and cobalt, the active auxiliary agent is fluorine, and the carrier is TiO 2 The number of parts by mass is 50 parts, and the catalyst number of this embodiment is D-02.

[0037] The preparation method of present embodiment catalyst is as follows:

[0038] 1) Mix 58.2g TiCl with 40g pseudo-boehmite powder, fully grind in a ball mill for 8 hours, and then roast at 600°C for 4 hours to obtain TiO 2 -Al 2 o 3 carrier;

[0039] 2) Add 1gMoO 3 , 1gFe 2 o 3 , 95.1gCo(NO 3 ) 2. 6H 2 O, 81gNi(CH 3 COO) 2 4H 2 O and 0.2gNaF were dissolved in 100g water to make a mixed solution;

[0040] 3) Mix the carrier prepared in step 1) with the mixed solution in step 2), knead fully, extrude into strips with a diameter of 2mm, dry at 100°C for 4 ...

Embodiment 3

[0042] Present embodiment catalyst comprises the component of following mass parts:

[0043] 30 parts of active component, 1 part of active auxiliary agent, 69 parts of carrier, wherein the active ingredient is molybdenum, nickel and iron, active auxiliary agent is phosphorus and fluorine, ZrO in the carrier 2 The number of parts by mass is 30 parts, and the catalyst number of this embodiment is D-03.

[0044] The preparation method of present embodiment catalyst is as follows:

[0045] 1) 39.2gZrCl 4 Dissolve in 100g of water, then immerse 48.3g of alumina pellets into the prepared zirconium salt solution, soak at room temperature for 4 hours, dry at 120°C for 2 hours, and roast at 300°C for 6 hours to obtain ZrO 2 -Al 2 o 3 carrier;

[0046] 2) 24.5g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 8.4gNiCO 3 2Ni(OH) 2 4H 2 O, 25.3gFe(NO 3 ) 3 .9H 2 O and 1.4gH 3 PO 4 Dissolve in 100g of water to make a mixed dipping solution;

[0047] 3) Immerse the carrier prepared in step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com