Hard alloy coating furnace

A cemented carbide and coating technology, applied in the field of metallurgical auxiliary equipment, can solve the problems of excessive cooling and product deformation, and achieve the effect of product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

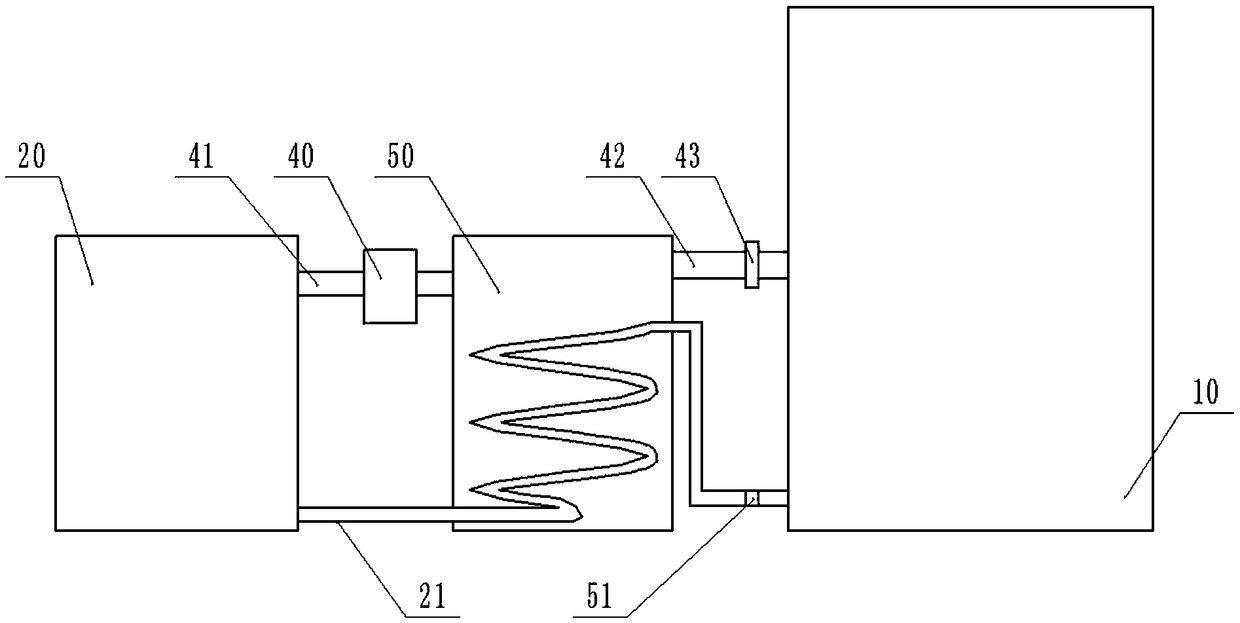

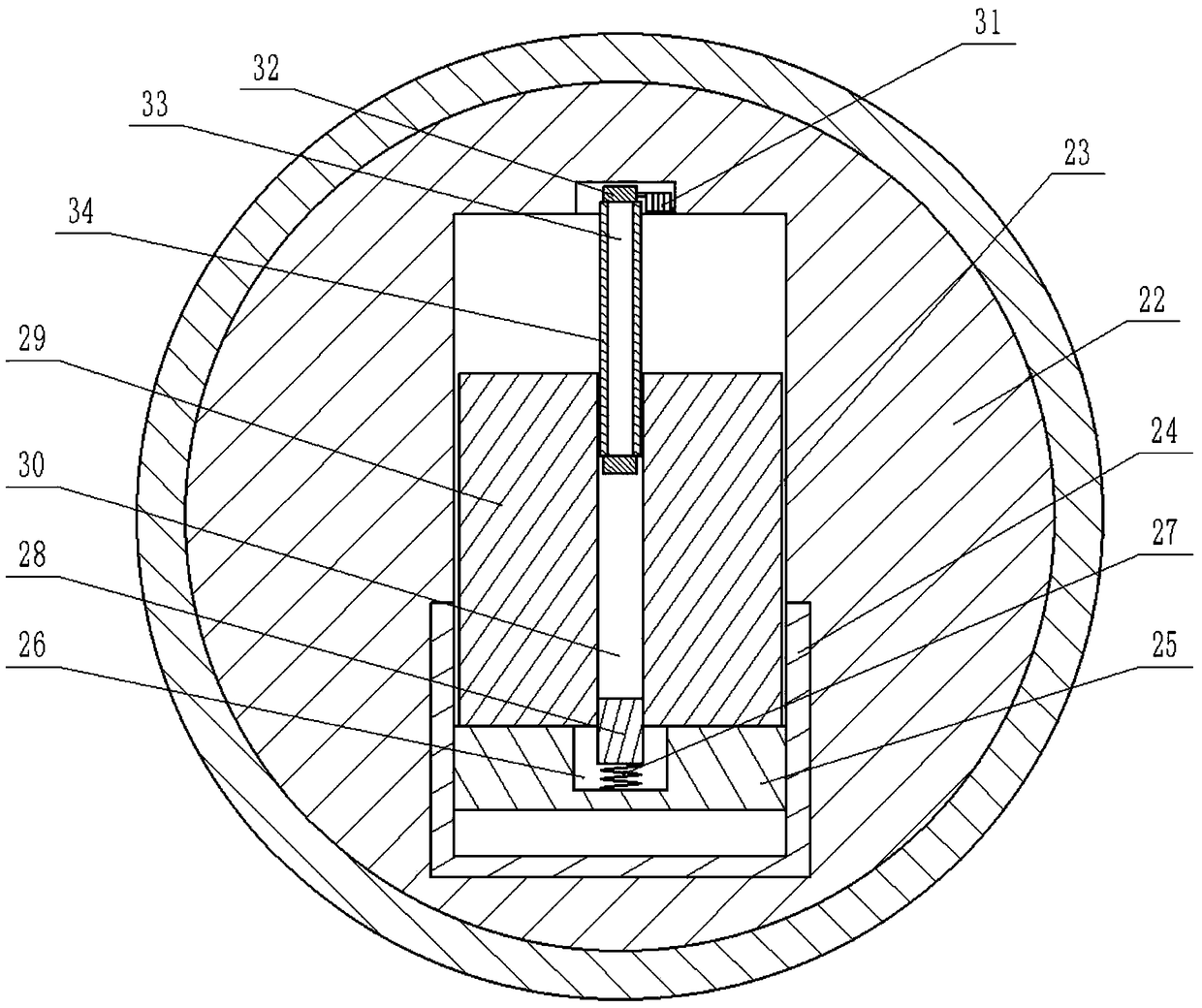

[0016] The reference signs in the accompanying drawings include: furnace body 10, first cooling box 20, suction pipe 21, baffle plate 22, first through groove 23, piston cylinder 24, piston 25, spring groove 26, spring 27, slide Column 28, slider 29, through hole 30, torsion spring 31, ejector rod 32, second through groove 33, sealing column 34, air extractor 40, first air outlet pipe 41, second air outlet pipe 42, one-way valve 43 , the second cooling box 50, and the switching device 51.

[0017] Such as figure 1 As shown, the cemented carbide coating furnace in this embodiment includes a furnace body 10 , a first cooling box 20 and a second cooling box 50 . Both the first cooling box 20 and the second cooling box 50 store low-temperature flue gas at a temperature of 100°C. The first cooling box 20 is communicated with a suction pipe 21, and the right end of the sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com