High-altitude municipal wastewater treatment method based on nitrogen and phosphorus capture and whole-course autotrophic nitrogen removal

A whole-process autotrophic denitrification and urban sewage technology, applied in the field of high-altitude urban sewage treatment, can solve the problems of inability to use CPNA pretreatment, not paying attention to ammonia nitrogen retention, and excessive residual COD, so as to achieve resource utilization and reduce sewage treatment. The effect of energy consumption and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

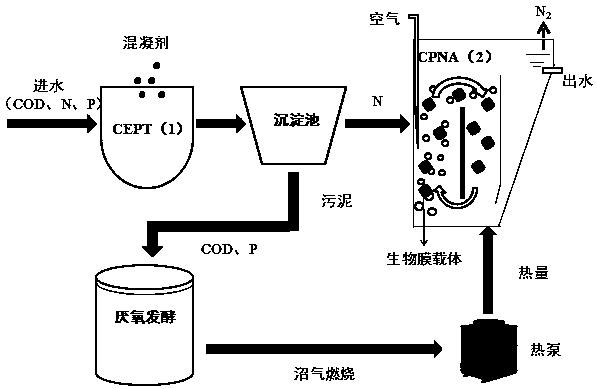

[0045] Embodiment 1: as figure 1 As shown, a high-altitude urban sewage treatment method based on nitrogen and phosphorus capture and full autotrophic denitrification. The domestic sewage first enters the CEPT reactor, and the carbon source and phosphorus are removed by adding flocculants. The effluent enters the sedimentation tank, and the flocs are removed by sedimentation. The supernatant of the sedimentation tank enters the CPNA reactor for denitrification, and then is discharged. The flocs in the sedimentation tank enter the anaerobic fermentation tank for anaerobic fermentation, and the biogas produced by the fermentation is burned, and the heat generated is transported to the CPNA reactor through a heat pump.

[0046] The present invention starts with improving the treatment effect of urban domestic sewage in high-altitude areas and reducing energy consumption for treatment, combines CEPT and CPNA processes, focuses on resource utilization of domestic sewage, and focuse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com