Method for dispersion of multi-walled carbon nanotubes

A multi-walled carbon nanotube and dispersion technology, applied in the nanometer field, can solve problems such as waste, and achieve the effects of small size, good water solubility, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

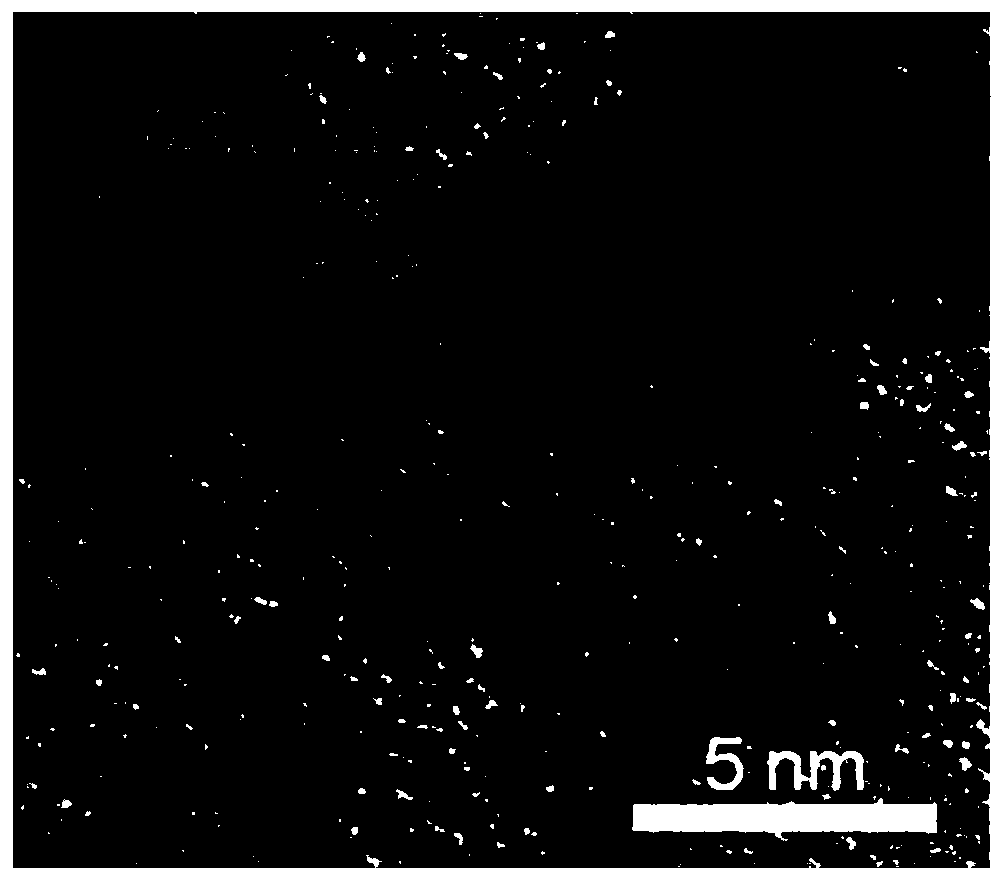

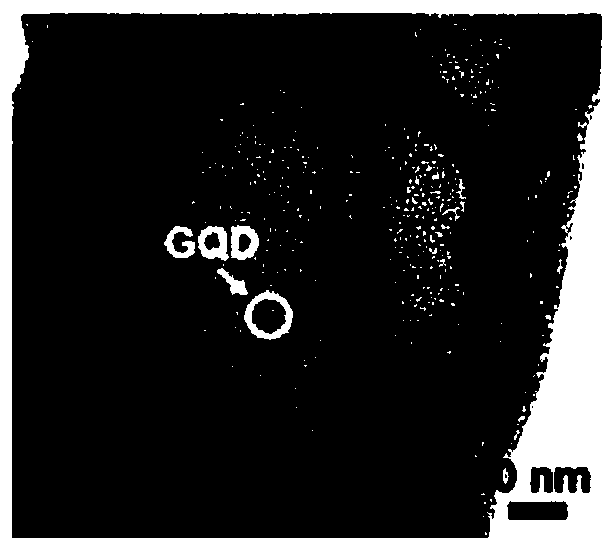

[0017] Choose carbonized polyimide film at 1300°C as the positive electrode material, immerse in 0.01mol / L ammonium sulfate electrolyte, and conduct electrolysis at a voltage of 10V for 1h;

[0018] Through the above steps, the graphene carbon dots dispersed in the electrolytic solution are obtained, ammonium sulfate is removed by dialysis, and the graphene carbon dot dispersion liquid with an oxygen content of 10% is obtained. Mix 400mL, 0.2mg / mL graphene carbon dots and 300mg multi-walled carbon nanotubes in a beaker, then place the beaker in an ultrasonic machine with an ultrasonic power of 400W, and stir with a stirring paddle at a speed of 100rmp. After 2 hours, excess carbon dots were filtered off, and undispersed multi-walled carbon nanotubes were removed to obtain a carbon tube dispersion concentration of 0.4 mg / mL. The carbon tube solution and graphene oxide are compounded and made into fibers, which can be used as supercapacitors, and the mass specific capacity can r...

Embodiment 2

[0022] Choose 800°C carbonized polyimide film as the positive electrode material, immerse in 0.05mol / L ammonium chloride electrolyte, and perform electrolysis at a voltage of 3V for 10h;

[0023] Through the above steps, the graphene carbon dots dispersed in the electrolytic solution are obtained, ammonium chloride is removed by dialysis, and the graphene carbon dot dispersion liquid with an oxygen content of 20% is obtained. Mix 400mL, 0.2mg / mL graphene carbon dots and 300mg multi-walled carbon nanotubes in a beaker, then place the beaker in an ultrasonic machine with an ultrasonic power of 270W while stirring with a stirring paddle at a speed of 50rmp. After 2 hours, excess carbon dots were filtered off, and undispersed multi-walled carbon nanotubes were removed to obtain a carbon tube dispersion concentration of 0.6 mg / mL. The carbon tube solution and graphene oxide are compounded and made into fibers, which can be used as supercapacitors, and the mass specific capacity can...

Embodiment 3

[0025] Choose carbonized polyimide film at 2200°C as the positive electrode material, immerse in 0.01mol / L ammonia water electrolyte, and conduct electrolysis at a voltage of 5V for 24 hours;

[0026] Through the above steps, the graphene carbon dots dispersed in the electrolytic solution are obtained, the ammonia water is removed by evaporation, and the graphene carbon dot dispersion liquid with an oxygen content of 40% is obtained. Mix 400mL, 0.2mg / mL graphene carbon dots and 400mg multi-walled carbon nanotubes in a beaker, then place the beaker in an ultrasonic machine with an ultrasonic power of 350W and stir with a stirring paddle at a speed of 60rmp. After 2 hours, excess carbon dots were filtered off, and undispersed multi-walled carbon nanotubes were removed to obtain a carbon tube dispersion concentration of 0.8 mg / mL. The carbon tube solution and graphene oxide are compounded and made into fibers, which can be used as supercapacitors, and the mass specific capacity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com