Method for incinerating dangerous solid wastes by utilizing high-concentration oxygen

A high-concentration oxygen and dangerous technology, used in combustion methods, incinerators, combustion types, etc., can solve the problems of insufficient combustion, low oxygen concentration, hazards, etc., to reduce energy consumption, reduce flue gas volume, The effect of reducing smoke loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

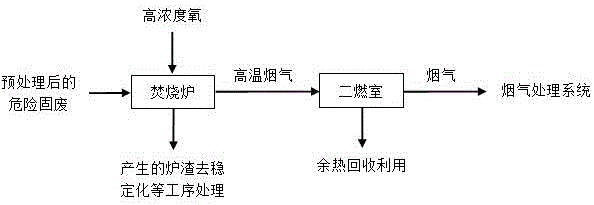

[0019] Such as figure 1 As shown, the hazardous waste produced by a certain petrochemical industry is pretreated by compaction, crushing, shearing, etc., and then sent to the rotary furnace incinerator through the hopper, and 85% preheated high-concentration oxygen is blown into the same end. , the mass ratio of hazardous solid waste to high-concentration oxygen is 1:5, so that hazardous solid waste and high-concentration oxygen are fully contacted, and incinerated in an incinerator for harmless treatment. The incineration temperature is 1000°C and the incineration time is 7s; The slag produced by incineration is treated by conventional methods such as destabilization and other processes; the generated high-temperature flue gas is passed into the secondary combustion chamber for complete combustion, the temperature is 1100 °C, the residence time of the flue gas in the secondary combustion chamber is 10S, and the outlet tail gas comes out The amount of dioxin is ≤0.03%, and the...

Embodiment 2

[0021] Such as figure 1 As shown, the hazardous solid waste produced by an electronics factory is sent to the fluidized bed incinerator through the hopper after pretreatment, and 50% preheated high-concentration oxygen is blown into the same end, and the hazardous solid waste and high-concentration The mass ratio of oxygen is 1:4, so that hazardous solid waste can be fully contacted with high-concentration oxygen, and incinerated for harmless treatment in the incinerator. The temperature of the incinerator is 2000°C, and the incineration time is 2s; Methods: Destabilization and other processes were carried out; the generated high-temperature flue gas was passed into the secondary combustion chamber for complete combustion, the temperature was 1000°C, the residence time of the flue gas in the secondary combustion chamber was 2S, and the amount of dioxin in the outlet tail gas was ≤0.04% , the amount of flue gas is reduced by 70%; the waste heat generated in the incineration is ...

Embodiment 3

[0023] Such as figure 1 As shown, a hospital waste is pretreated and sent to the blast furnace hot air incinerator through a hopper, and preheated 100% high-concentration oxygen is blown into the same end. The mass ratio of hazardous solid waste to high-concentration oxygen is 1 :3. Make the hazardous solid waste fully contact with high-concentration oxygen, and carry out incineration and harmless treatment in the incinerator. The incineration temperature is 1300°C, and the incineration time is 5s; the slag produced by incineration is destabilized by conventional methods. Treatment; the high-temperature flue gas produced is passed into the secondary combustion chamber for complete combustion, the temperature is 1700°C, the residence time of the flue gas in the secondary combustion chamber is 3S, the amount of dioxin in the outlet tail gas is ≤0.02%, and the amount of flue gas is reduced by 80% %; The waste heat generated in the incineration is used to preheat the high-concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com