Manufacturing method for antifouling and doodle-preventing polyurethane (PU) synthetic leather

A manufacturing method and anti-graffiti technology, applied in the field of synthetic leather manufacturing, can solve the problems of poor stain resistance and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

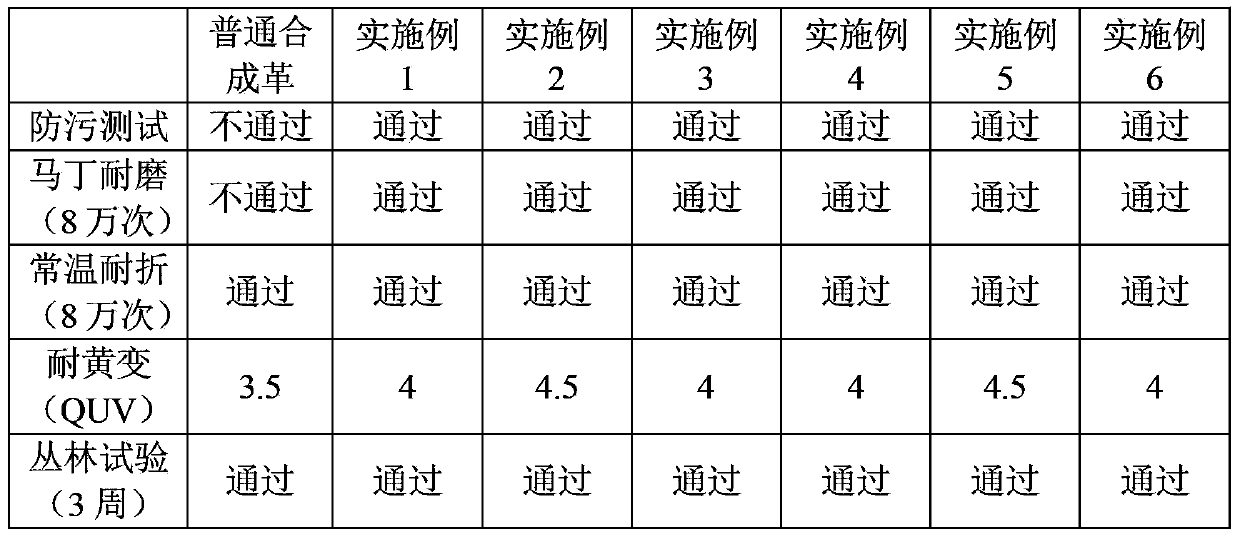

Examples

Embodiment 1

[0040] (a) Prepare synthetic leather dry-laid semi-finished products (using twill weave wet-laid base, using AP-T D90 release paper pattern), unwinding;

[0041] (b) Use the printing process to treat a layer of anti-fouling and anti-graffiti polyurethane working paste on the surface of the semi-finished product. The formula of the working paste is calculated as:

[0042] Ordinary polyurethane finishing resin (HT-109): 50 parts,

[0043] Antifouling and antigraffiti polyurethane resin (LS-91-077): 50 parts,

[0044] Antifouling and antigraffiti crosslinking agent (MA-2491): 5 parts,

[0045] Solvent (DMF): 50 parts,

[0046] Color paste: 5 parts,

[0047] The viscosity of the working slurry is 2000cps / 25℃, and the coating amount is 60g / m 2 ;

[0048] (c) drying and curing, the drying and curing temperature is 130°C, and the drying and curing time is 3 minutes;

[0049] (d) cooling and winding to obtain high anti-fouling and anti-graffiti polyurethane synthetic leather.

Embodiment 2

[0051] (a) Prepare synthetic leather cold-pressed semi-finished products (using plain weave wet-laid bottom blank, BN9 cold-pressed roller pattern), and unwind;

[0052] (b) Apply a roller coating process to treat a layer of anti-fouling and anti-graffiti polyurethane working paste on the surface of the semi-finished product. The formula of the working paste is calculated by mass as follows:

[0053] Antifouling and antigraffiti polyurethane resin (CF-113): 100 parts,

[0054] Antifouling and antigraffiti crosslinking agent (CA-263): 20 parts,

[0055] Solvent (MEK): 10 parts,

[0056] Color paste: 6 parts,

[0057] Other additives (JN3-018): 1 part;

[0058] The viscosity of the working slurry is 4000cps / 25℃, and the coating amount is 70g / m 2 ;

[0059] (c) Drying and curing, the drying and curing temperature is 150°C, and the drying and curing time is 4 minutes;

[0060] (d) Cooling and winding to obtain oily and waxy polyurethane synthetic leather with high anti-fouli...

Embodiment 3

[0062] (a) Prepare synthetic leather cold-pressing-finishing semi-finished products (use plain weave wet-laid bottom blank, BN9 cold-pressing roller pattern, print AN0 cloud color), and unwind;

[0063] (b) Apply a spraying process to treat a layer of anti-fouling and anti-graffiti polyurethane working slurry on the surface of the semi-finished product. The formula of the working slurry is calculated by mass as follows:

[0064] Ordinary polyurethane finishing resin (BLLK-7048N): 40 parts,

[0065] Antifouling and antigraffiti polyurethane resin (HH-LACK8008): 60 parts,

[0066] Antifouling and antigraffiti crosslinking agent (HH-LACK505): 3 parts,

[0067] Anti-fouling and anti-graffiti accelerator (HH-LACK303): 6 parts,

[0068] Solvent (EA): 100 parts,

[0069]Color paste: 10 parts,

[0070] Other additives (JN3-056): 0.5 parts;

[0071] The viscosity of the working slurry is 100cps / 25℃, and the coating amount is 150g / m 2 ;

[0072] (c) Drying and curing, the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com