High gloss flame retardant anti-bacterial and weatherproof polypropylene composite material and preparation method thereof

A technology of weather-resistant polypropylene and composite materials, applied in the field of polymers, can solve problems such as poor gloss, poor weather resistance, and low antibacterial efficiency, and achieve the effects of improved weather resistance, small mechanical properties, and improved antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

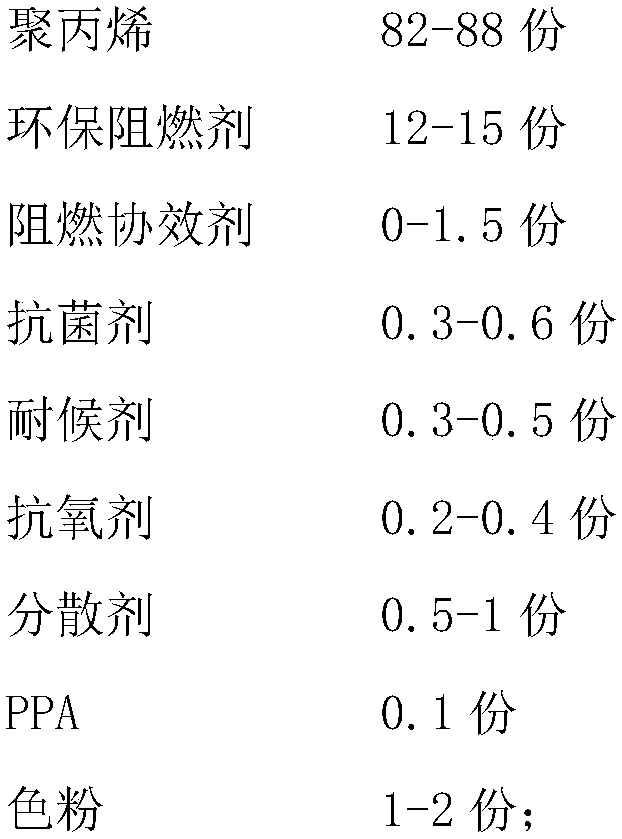

[0032] The high-light flame-retardant antibacterial and weather-resistant polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0033]

[0034]

[0035] Concrete preparation method comprises the following steps:

[0036] (1) According to the proportioning ratio, disperse 0.3 part of antibacterial agent and 0.2 part of calcium stearate evenly in the high mixer, and set aside;

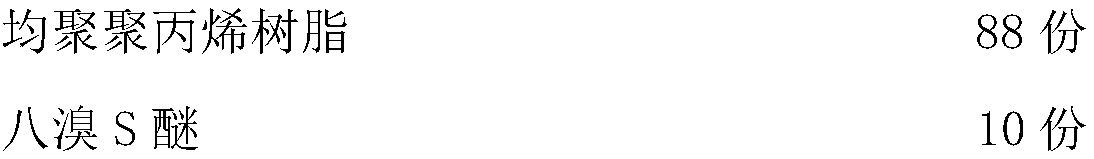

[0037] (2) Put 88 parts of homopolypropylene, 10 parts of octabromo-S ether, and 2 parts of antimony trioxide into the mixer in proportion, and mix for 3-5 minutes;

[0038] (3) 0.3 part of mixed material in step (1) and hindered amine light stabilizer, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.3 part of calcium stearate, 0.1 part of polytetrafluoroethylene, Add 1 part of titanium dioxide to the mixer that has been mixed in step (2), and continue mixing for 3-5 minutes;

[0039] (4) Put the mixed material in the step (3) int...

Embodiment 2

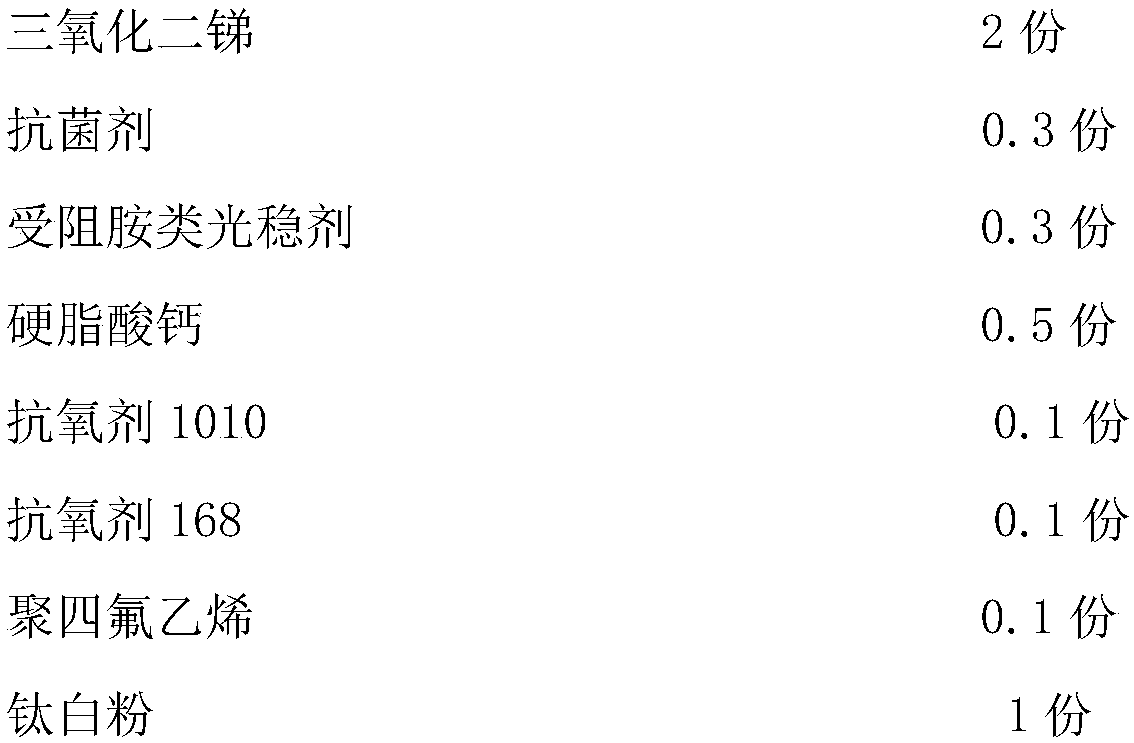

[0041] The high-light flame-retardant antibacterial and weather-resistant polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0042]

[0043]

[0044] Concrete preparation method comprises the following steps:

[0045] (1) According to the proportioning ratio, disperse 0.3 part of antibacterial agent and 0.2 part of calcium stearate evenly in the high mixer, and set aside;

[0046] (2) Put 83 parts of homopolypropylene, 12 parts of octabromo-S ether, 3 parts of antimony trioxide, and 0.5 parts of cooling masterbatch into the mixer in proportion, and mix for 3-5 minutes;

[0047] (3) Combine the mixed material in step (1) with 0.3 parts of hindered amine light stabilizer, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.3 part of calcium stearate, and 0.1 part of polyvinylidene fluoride , 1 part of titanium dioxide is added to the mixer that has been mixed in step (2), and the mixture is continued for 3-...

Embodiment 3

[0050] The high-light flame-retardant antibacterial and weather-resistant polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0051]

[0052]

[0053] Concrete preparation method comprises the following steps:

[0054] (1) According to the proportioning ratio, disperse 0.3 part of antibacterial agent and 0.2 part of calcium stearate evenly in the high mixer, and set aside;

[0055] (2) Put 82 parts of homopolypropylene, 12 parts of octabromo-S ether, 3 parts of antimony trioxide, 1 part of anti-dripping agent, and 0.5 parts of cooling masterbatch into the mixer in proportion, and mix for 3-5 minute;

[0056] (3) Combine the mixed material in step (1) with 0.3 parts of benzotriazole weather-resistant agent, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.3 part of calcium stearate, and 0.1 part of polyvinylidene fluoride. 1 part, 1 part of titanium dioxide is added in the mixer that has been mixed in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com