Marble tile capable of degrading formaldehyde and its preparation method

A technology for marble and ceramic tiles, which is applied in the field of ceramic tiles and their preparation, can solve the problems of photocatalyst layer wear and consumption, low use value, etc., and achieve the effects of improving service life, increasing firmness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

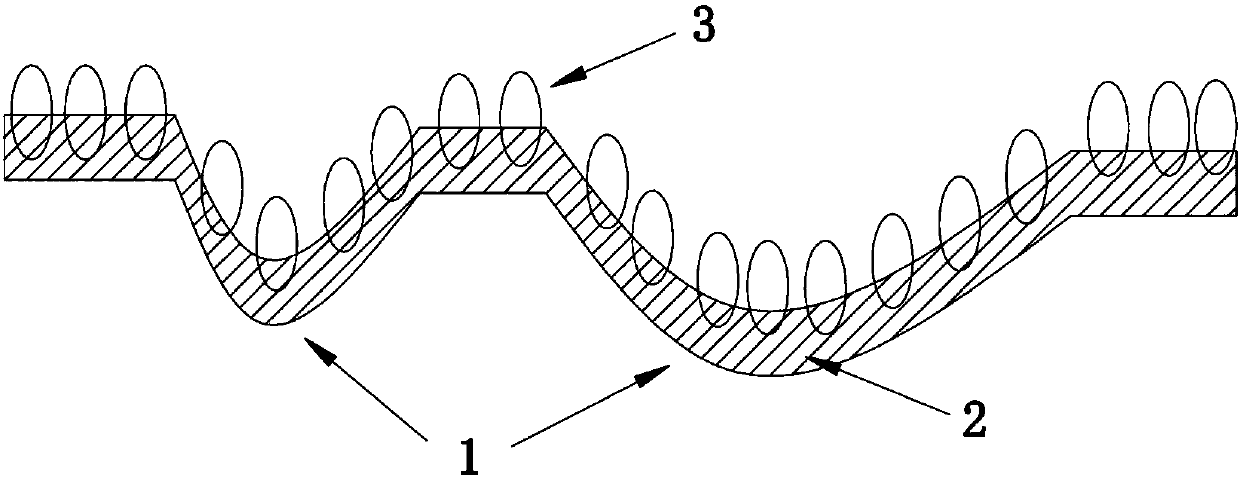

[0028] An embodiment of the formaldehyde-degradable marble tile described in the present invention, the structure diagram of the formaldehyde-degradable marble tile described in this embodiment is as attached figure 1 Shown:

[0029] It includes the marble tile base layer 1, the intermediate adhesive layer 2 solidified on the upper surface of the marble tile base layer 1, and the formaldehyde removal functional layer 3 combined with the upper surface of the intermediate adhesive layer 2. The upper surface of the marble tile base layer 1 is uneven, and the marble tile base layer 1 is a marble tile base layer with polished surface (polished marble tile with a porcelain surface), the middle adhesive layer 2 is an antifouling layer, the material of the middle adhesive layer 2 is an inorganic material, and the formaldehyde-removing functional layer 3 is a photocatalyst layer.

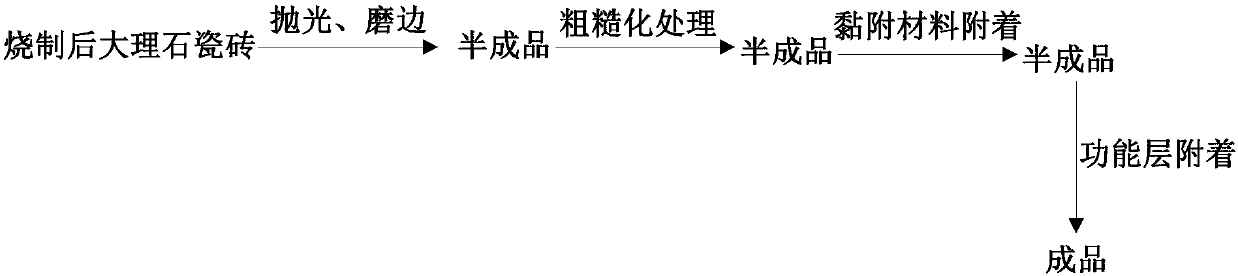

[0030] The preparation method of the formaldehyde-degradable marble tile described in this embodiment com...

Embodiment 2

[0034] An embodiment of the formaldehyde-degradable marble tile described in the present invention, the structure diagram of the formaldehyde-degradable marble tile described in this embodiment is as attached figure 1 Shown:

[0035] It includes the marble tile base layer 1, the intermediate adhesive layer 2 solidified on the upper surface of the marble tile base layer 1, and the formaldehyde removal functional layer 3 combined with the upper surface of the intermediate adhesive layer 2. The upper surface of the marble tile base layer 1 is provided with micropores. The tile base 1 is a marble tile base with polished surface (polished marble tile with enamel on the surface), the middle adhesive layer 2 is an adhesive layer, the material of the middle adhesive layer 2 is an organic material, and the formaldehyde-removing functional layer 3 is a formaldehyde scavenger layer .

[0036] The preparation method of the formaldehyde-degradable marble tile described in this embodiment ...

Embodiment 3

[0041] An embodiment of the formaldehyde-degradable marble tile described in the present invention, the structure diagram of the formaldehyde-degradable marble tile described in this embodiment is as attached figure 1 Shown:

[0042] It includes the marble tile base layer 1, the intermediate adhesive layer 2 solidified on the upper surface of the marble tile base layer 1, and the formaldehyde removal functional layer 3 combined with the upper surface of the intermediate adhesive layer 2. The upper surface of the marble tile base layer 1 is provided with micropores. Ceramic tile base 1 is a polished marble tile base (polished marble tile with enamel on the surface), and the intermediate adhesive layer 2 includes an antifouling layer and an adhesive layer. The material of the intermediate adhesive layer 2 is a mixture of organic materials and inorganic materials. The formaldehyde functional layer 3 is a formaldehyde dissolving enzyme layer.

[0043] The preparation method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com