Floating blockage-proof energy-saving low-noise intermediate conveying device

A conveying device and anti-clogging technology, which is applied in the field of floating, anti-clogging, energy-saving and low-noise intermediate conveying devices, can solve problems such as increasing machine noise and increasing power consumption, and achieve the effects of reducing noise, reducing power consumption and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

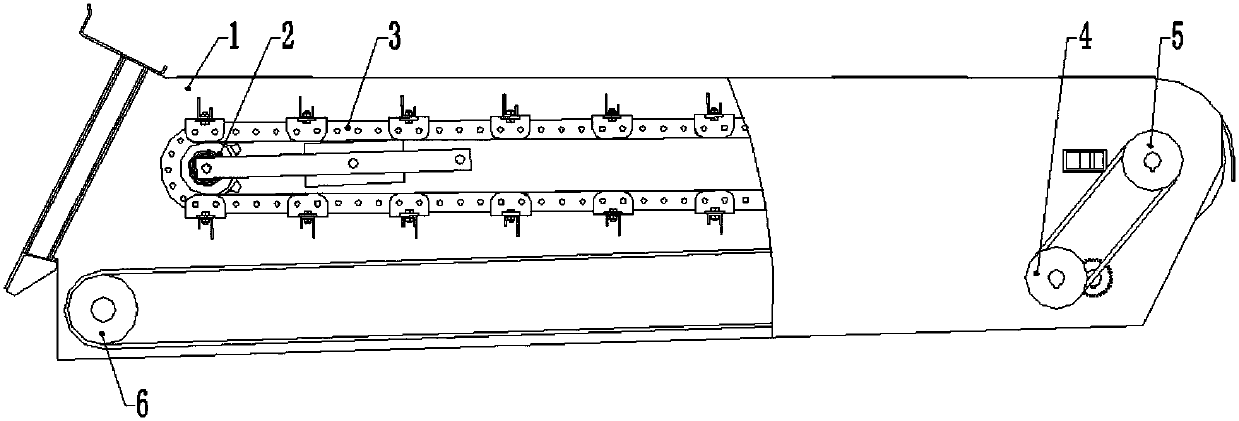

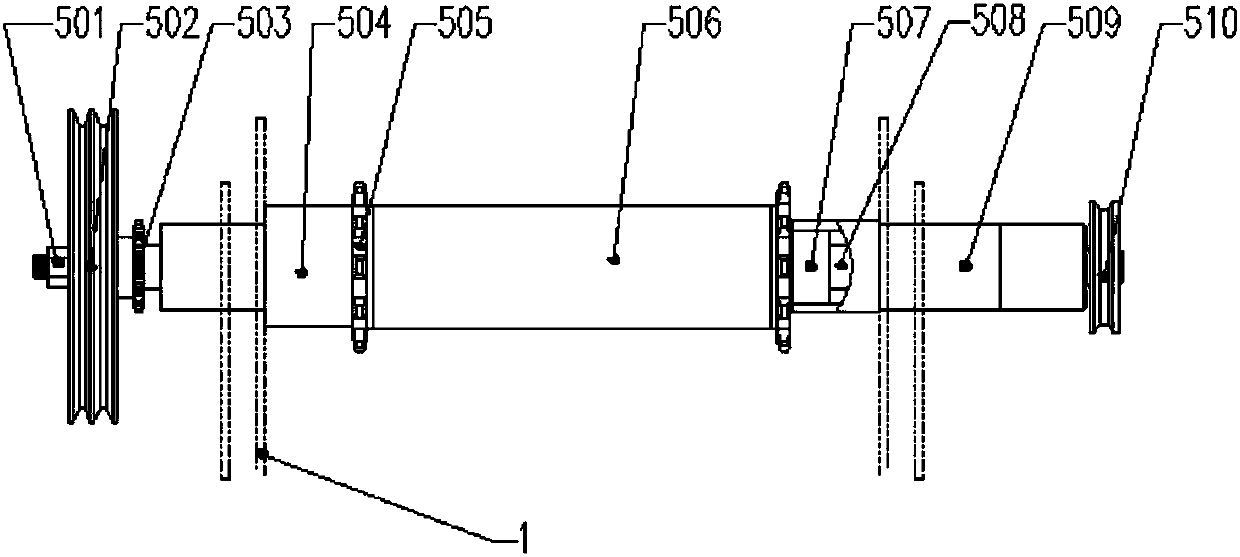

[0026] like figure 1 As shown, the floating anti-blocking energy-saving and low-noise intermediate conveying device of the present invention includes a frame 1, a driven shafting 2, a chain 3, a secondary driving shafting 4, a driving shafting 5, and a lower conveyor belt system 6. The driven shaft system 2 is installed on the left end of the frame 1; the driving shaft system 5 is installed on the right end of the frame 1; ; The lower conveyor belt system 6 is installed below the driving shafting 5 and the driven shafting 2, and gear transmission is used between the auxiliary driving shafting 4.

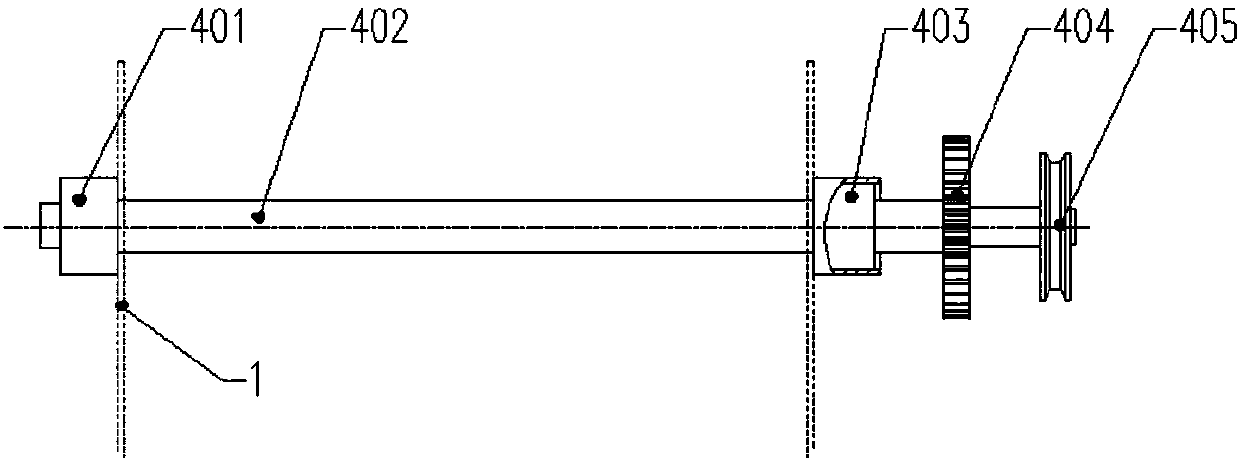

[0027] like figure 2 As shown, the auxiliary driving shaft system 4 is mainly composed of bearings B403, gears A404, and pulleys C405; Stretch out the frame 1, the gear A404...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com