Over thick wood chip crusher

A wood chip and crusher technology, applied in the direction of raw material separation, can solve the problems of ineffective utilization of wood resources, high fragmentation rate, wood fiber damage, etc., and achieves good re-shredding effect, low fragmentation rate, and easy operation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples, but these embodiments do not limit the protection scope of the present invention.

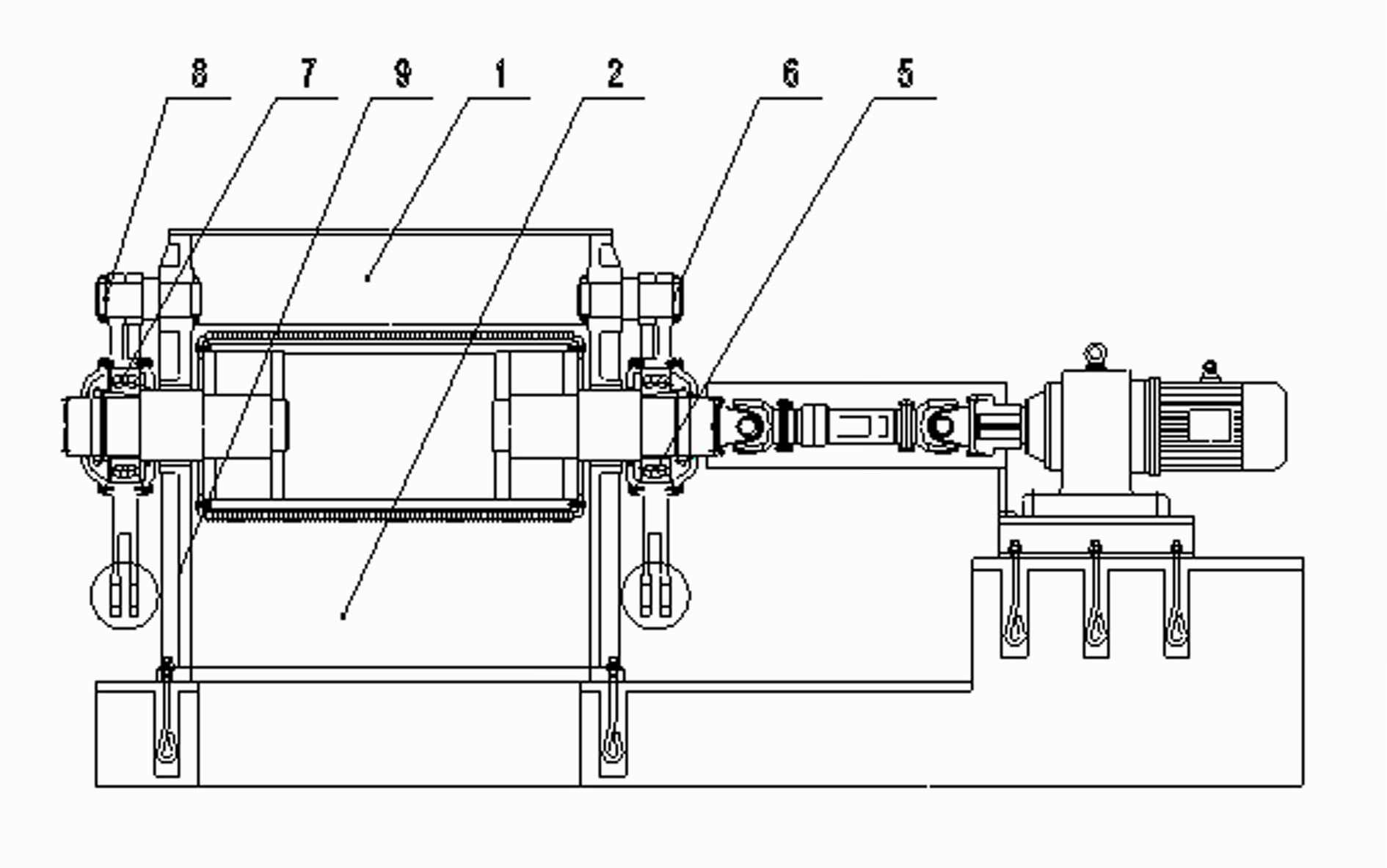

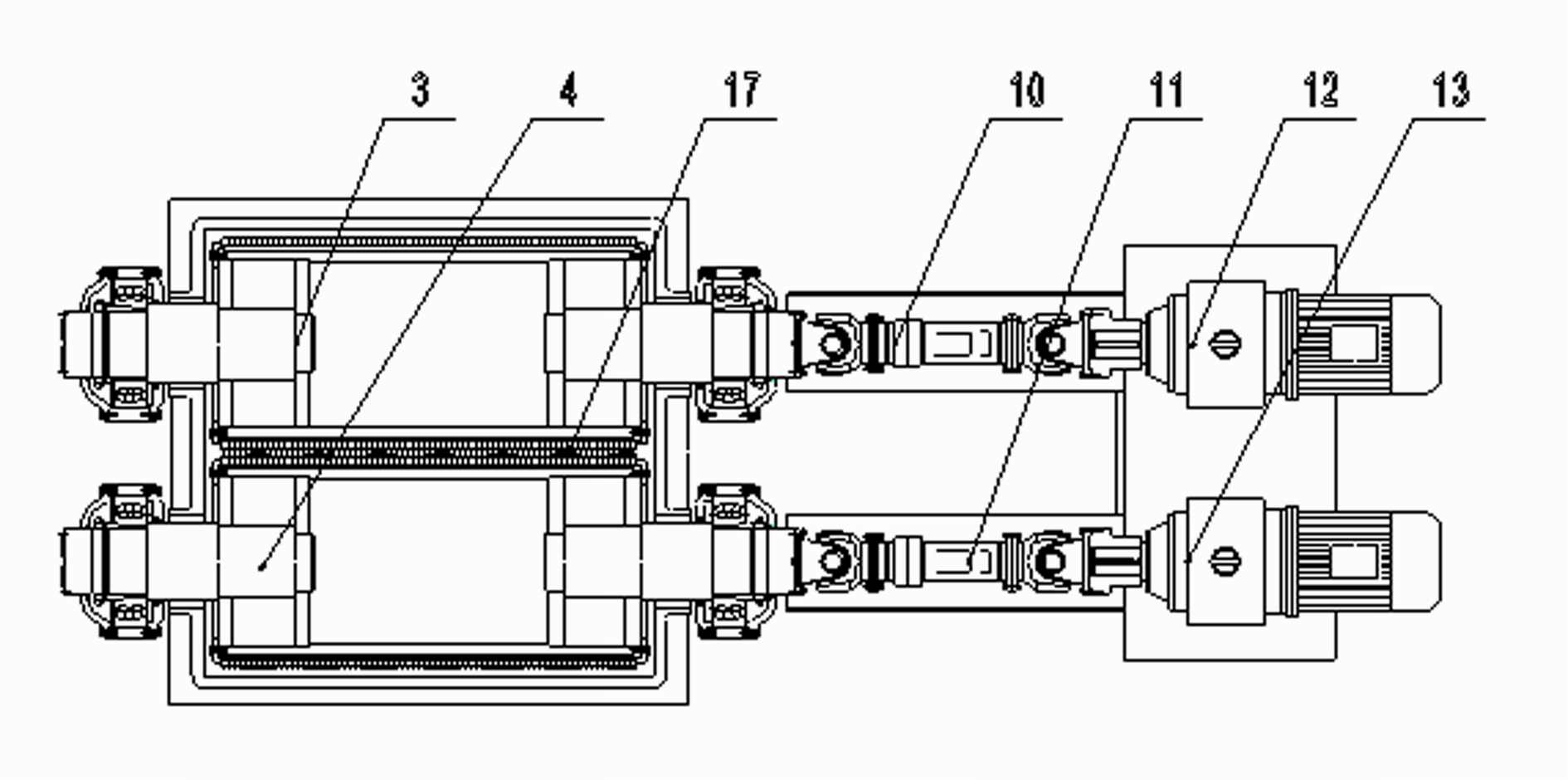

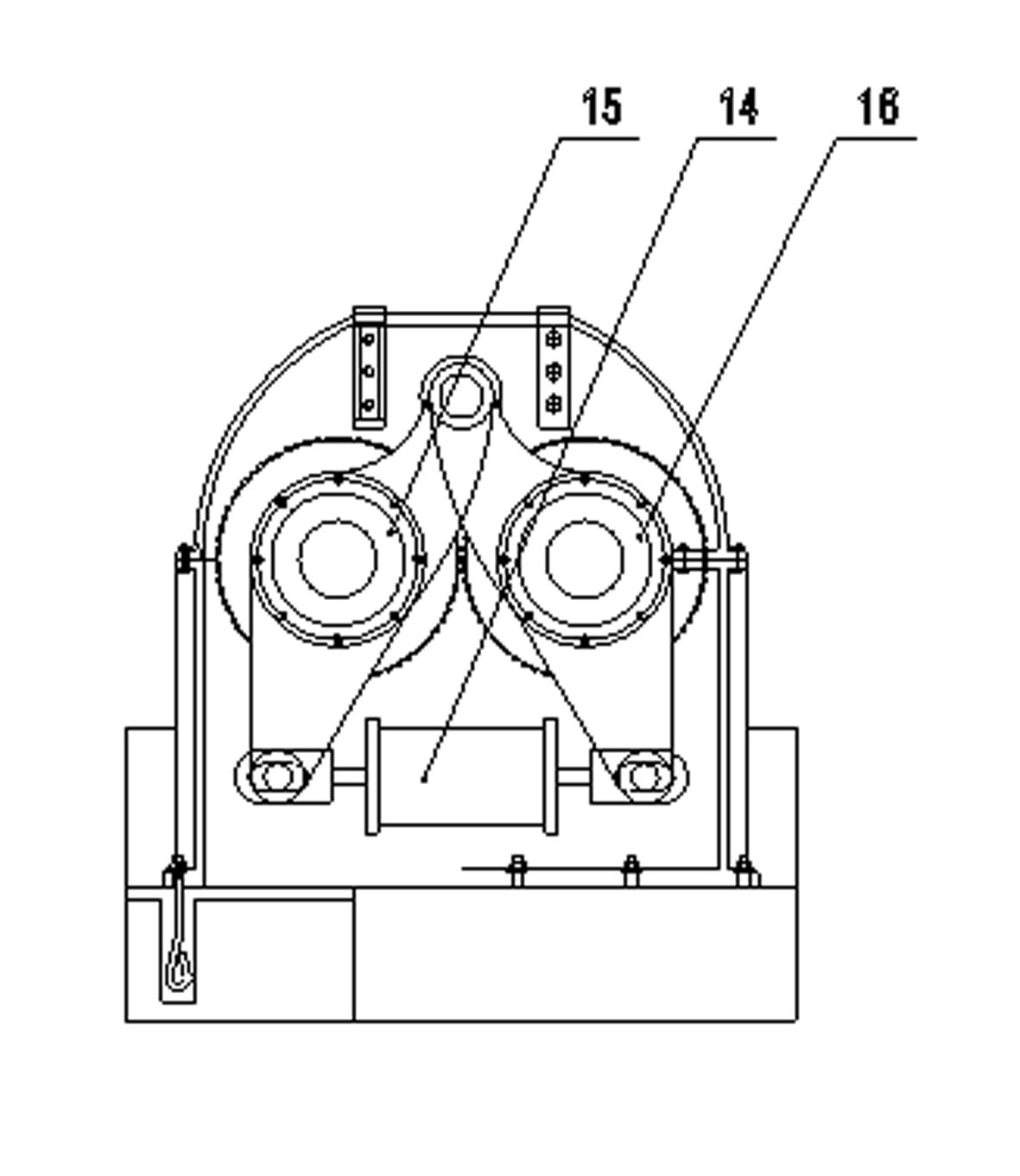

[0014] Such as figure 1 , figure 2 , image 3 As shown, the casing 9 of the present invention is a fixed box-type structure, which is divided into detachable upper and lower parts. There are supporting short shafts 6, 8 at both ends of the casing. The upper pressure roller 3 and the lower pressure roller 4, the two pressure rollers have the same diameter, equal rotational speed, and opposite directions. The surface of each pressure roller is regularly covered with grooves and convex teeth. The ring gear is assembled, and the ring gear is made of wear-resistant materials; the pressure roller and the pressure roller are parallel to each other, and are installed on the supporting short shaft through the rocker arm bearing seat 15, 16, and are combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com