Automatic printing interval adjusting lettering method and device

An automatic adjustment and gap technology, applied in the direction of power transmission device, printing, transfer materials, etc., can solve the problems of increasing the deflection angle between the print head and the printing platform, affecting the life of the print head, and affecting the printing medium, etc., and achieve the production cost. Low, strong practical value, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

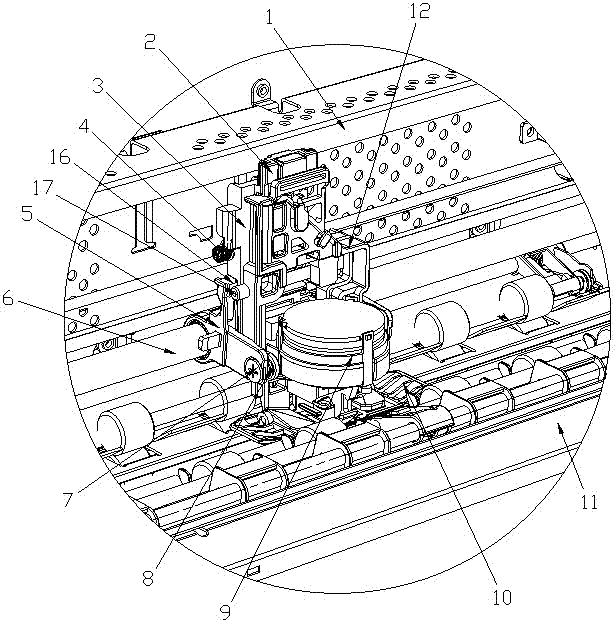

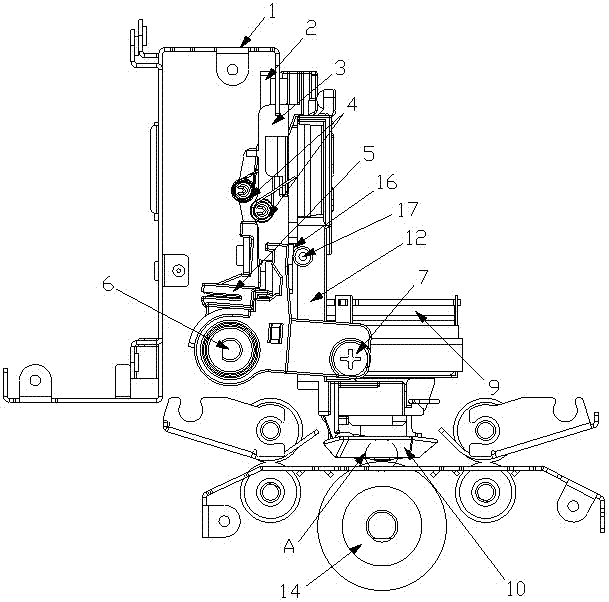

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

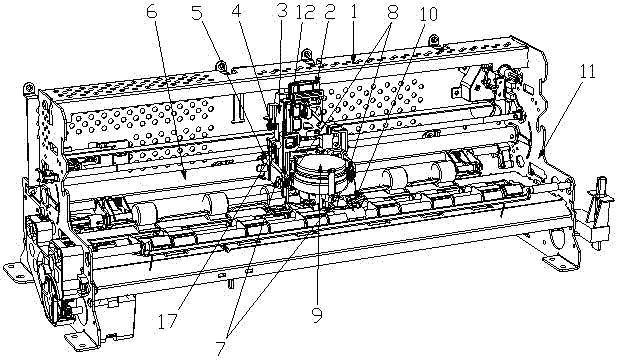

[0022] Such as Figure 1~6 As shown in the figure, a printing device for automatically adjusting the printing gap includes a printer body, the printer body is provided with a carriage assembly and a guide rail 1 for guiding the carriage assembly to move laterally, and the two ends of the guide rail 1 are fixed on a frame 11 , the character car assembly includes character car guide shaft 6, character car split body A 5, character car split body B 3, character car split body C 12 and print head 9, and the print head 9 is installed on character car split body C 12, the rear part of the character car split body A5 and the lower part of the character car split body B3 are respectively rotatably sleeved on the character car guide shaft 6, and the character car split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com