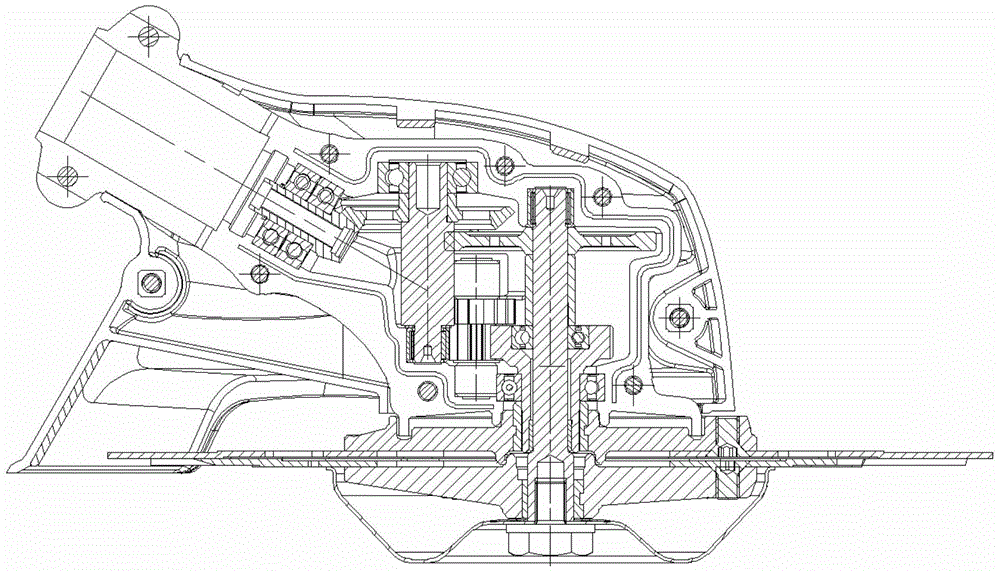

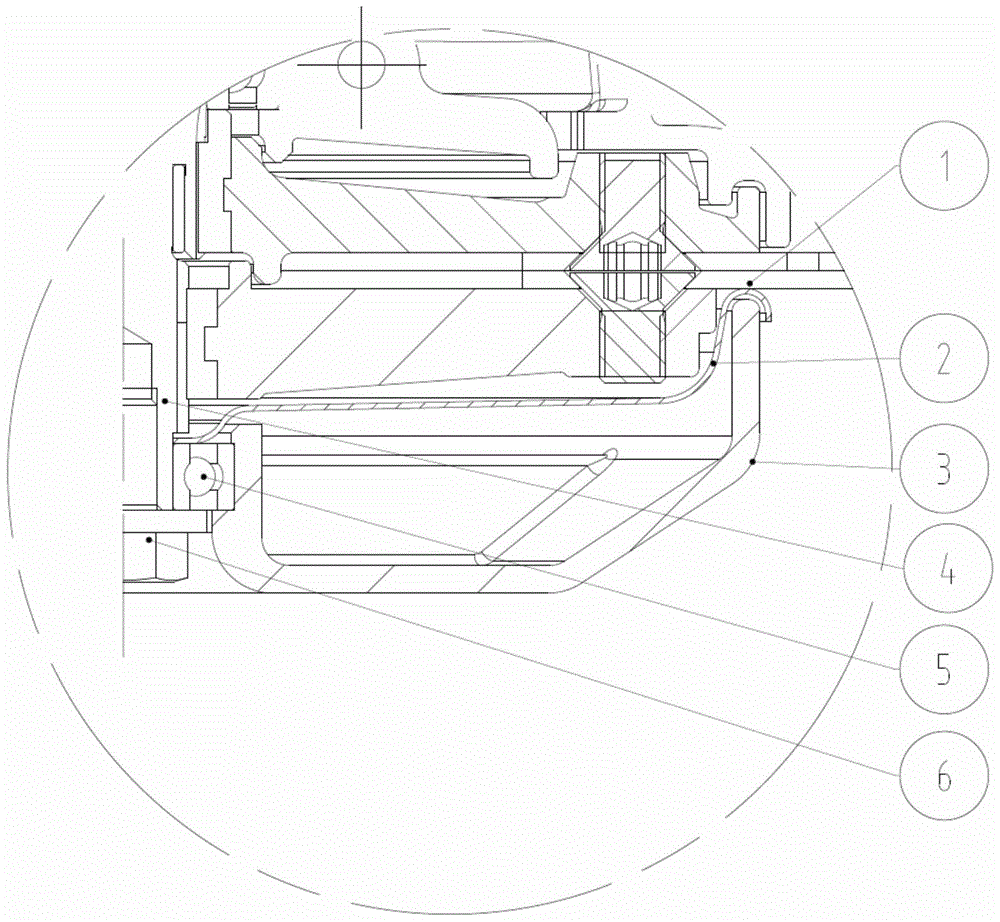

A bearing support structure applied to a double-blade bidirectional rotary lawn mower

A bi-directional rotation, bearing support technology, applied in the direction of lawn mowers, applications, harvesters, etc., can solve problems such as abnormal operation, reduced work efficiency, bottom cover cracking, etc., to achieve the elimination of cracking or severe wear, and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention utilizes the characteristics of the force deformation of the disc spring to control the pressure between the upper and lower blades to a set value within a small range, and the noise is low. The cut way works.

[0026] The bottom cover is separated from the blade by the disc spring, and the bottom cover is separated from the output shaft by the bearing. The bottom cover itself does not rotate, and it will not collide with hard objects such as the ground surface and stones, and there is no rupture or serious wear. It can ensure long-term effective work without damage; the bottom cover is made of nylon plastic, which is light in weight, reduces the burden on the operator, and improves work efficiency; the operator can place the body on the ground and drag it, so that the mower can cut smoothly without suspending the lawn mower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com