Disc brake caliper

A disc brake and brake caliper technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problem that the braking performance cannot be fully guaranteed, the elasticity of the piston seal ring, heat resistance, and wear resistance High surface roughness requirements and other problems, to achieve the effect of accurate return, reliable performance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

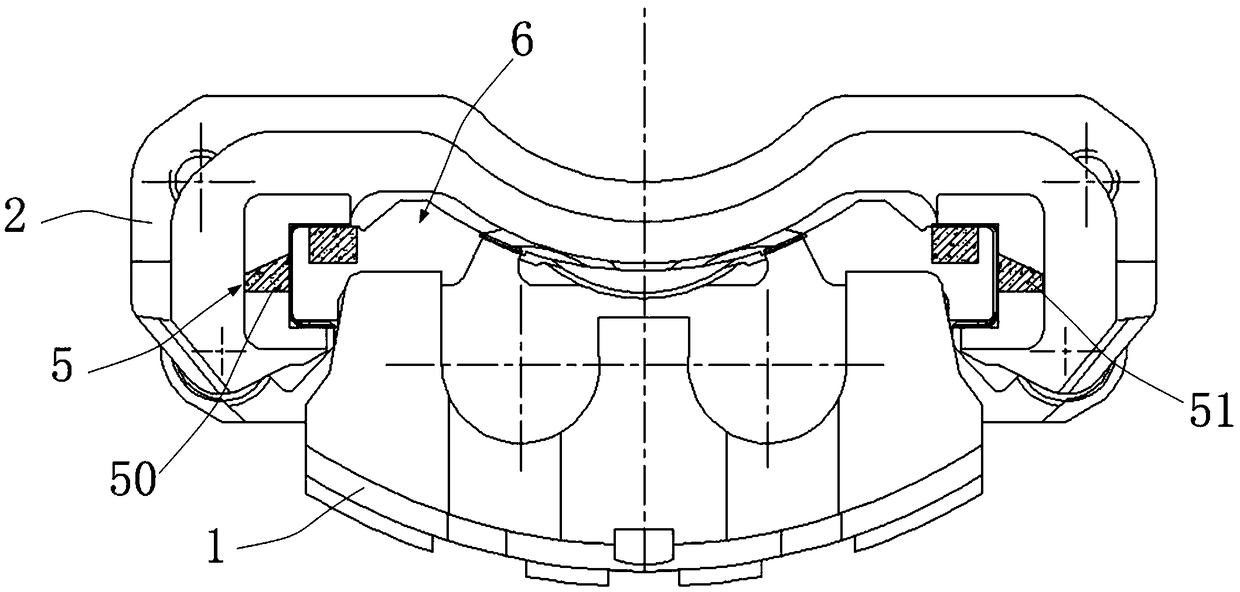

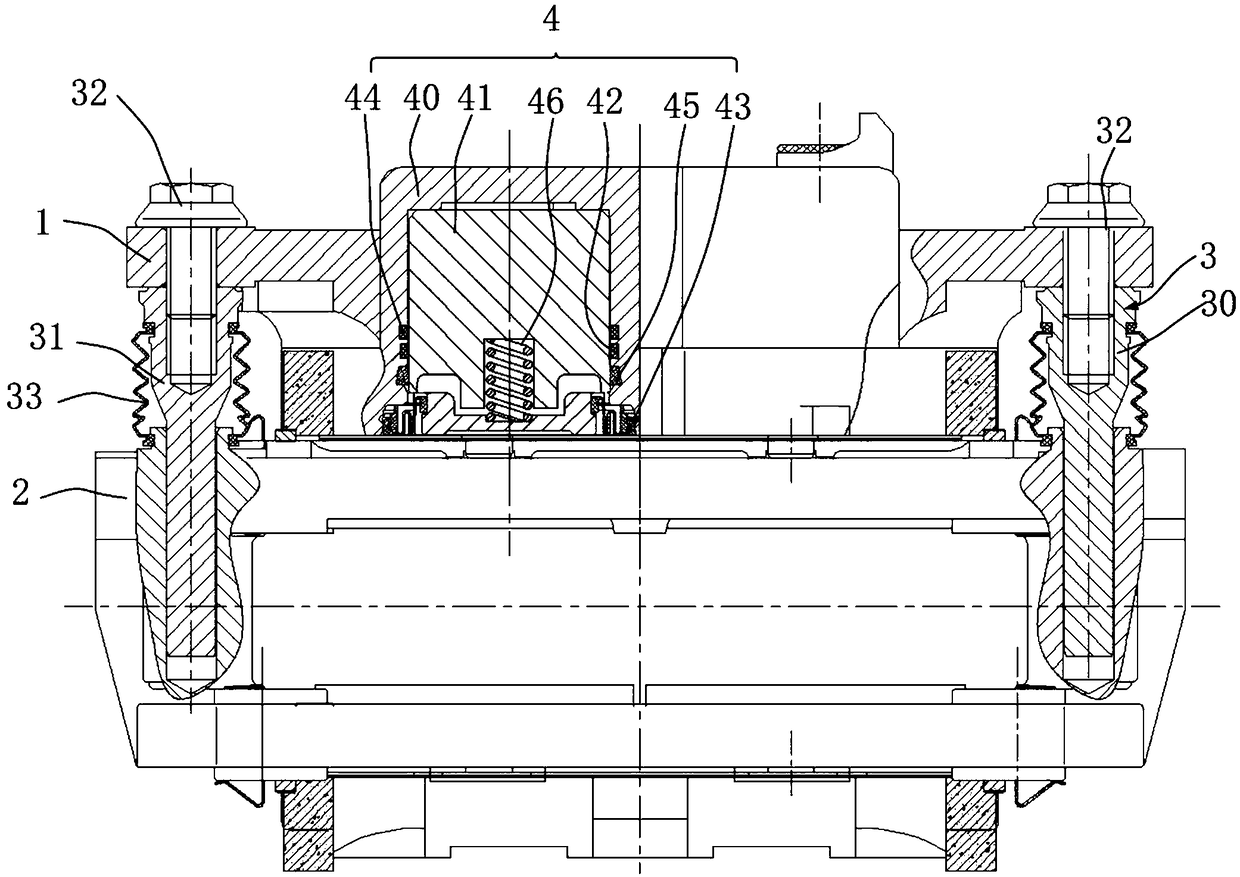

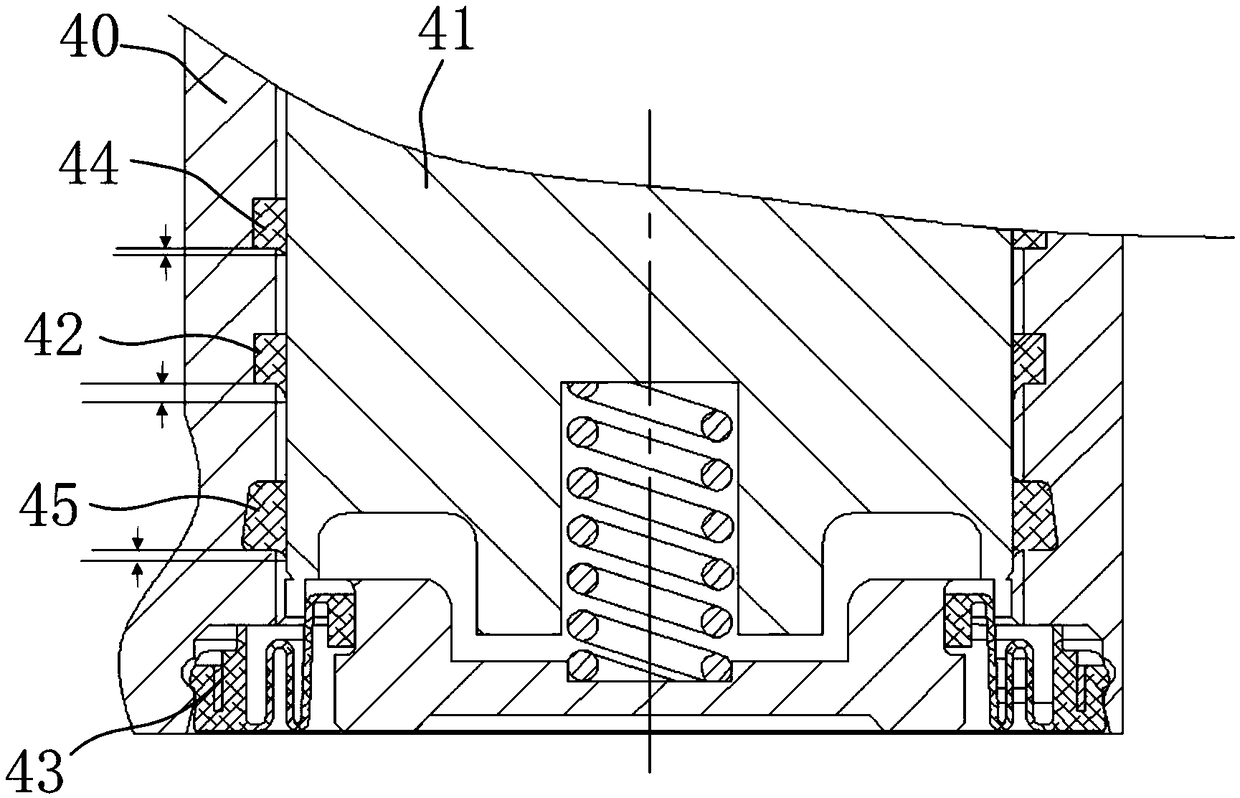

[0026] A disc brake caliper provided in an embodiment of the present application includes: a brake caliper body 1; a brake caliper bracket 2; a sliding shaft 3; the sliding shaft 3 includes: a main sliding shaft 30; an auxiliary sliding shaft 31; Sliding shaft bolt 32; sliding shaft dust cover 33; hydraulic cylinder 4; said hydraulic cylinder 4 includes a hydraulic cylinder block 40; piston 41; piston sealing ring 42; piston dustproof ring 43; guide ring 44; And return spring 46; Stop spring 5; The stop spring 5 includes a first jumper 50; A second jumper 51; Friction block assembly 6; The brake caliper bracket 2 is fixed on the vehicle steering knuckle; The brake caliper body 1 is connected with the sliding shaft 3 through the sliding shaft bolt 32; the main sliding shaft 30 and the auxiliary sliding shaft 31 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com