Die return type full automatic flexible tube shoulder-injecting machine

A hose shoulder injection machine, return-type technology, applied in the direction of coating, etc., can solve the problems of high cost of use, high machine cost, high mold cost, etc., and achieve low machine manufacturing cost, simple action and structure, and easy mold replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

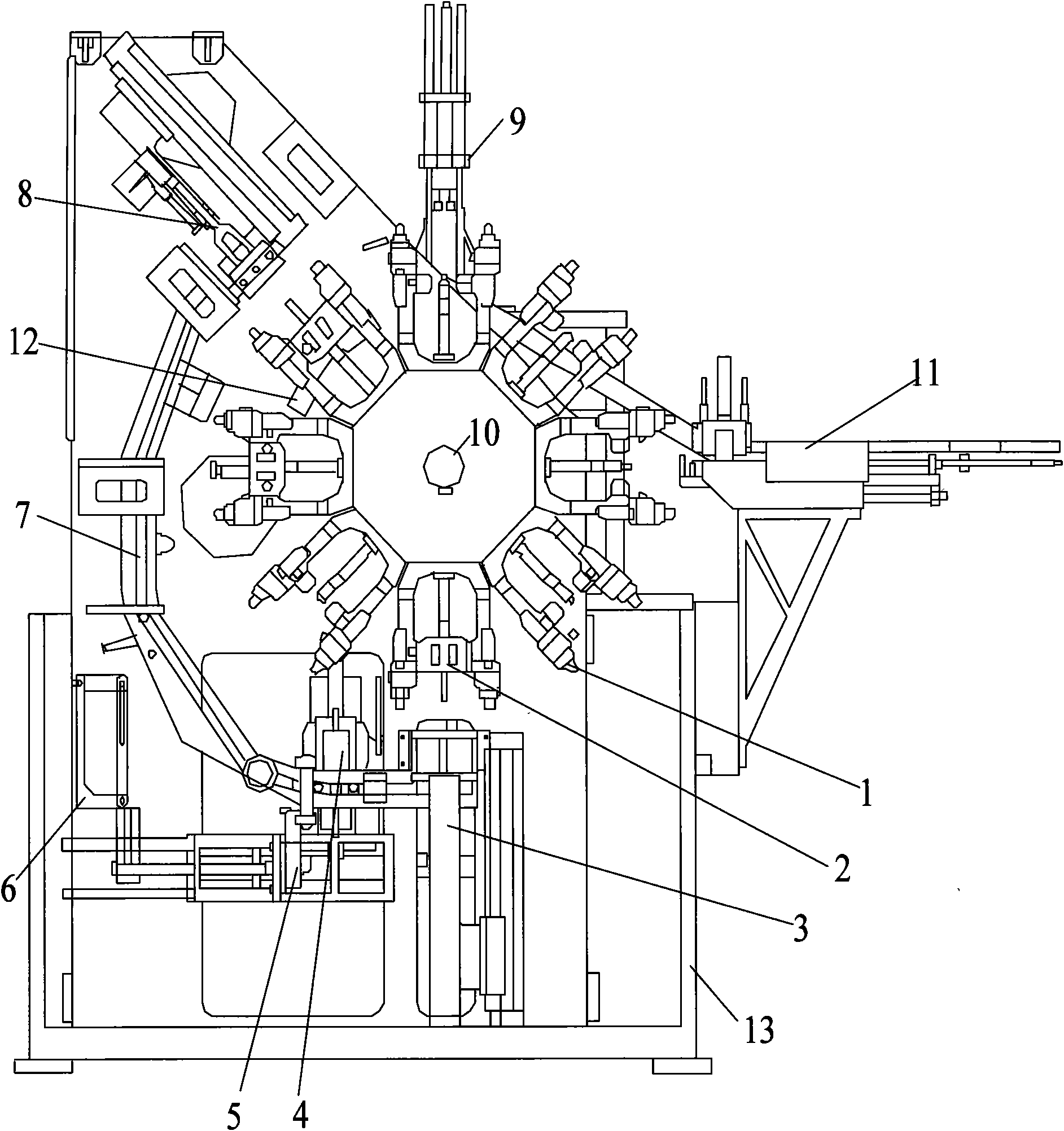

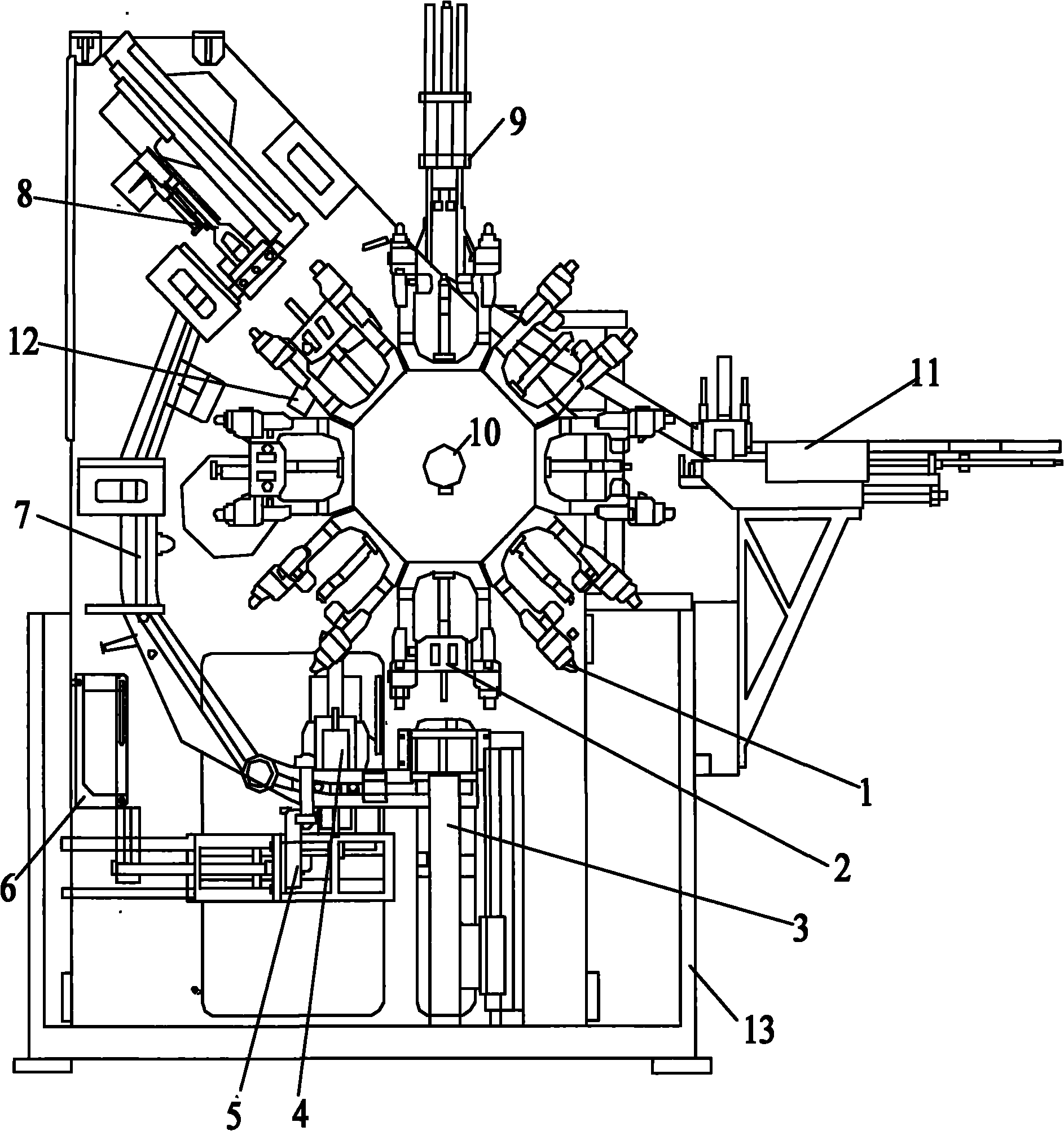

[0022] Such as figure 1 As shown, the mold return type automatic hose shoulder injection machine of the present invention adopts a vertical turntable operation mode, which can expand unlimitedly in the horizontal axis direction and produce at least two hoses, thereby improving production efficiency. The mold return type automatic hose shoulder injection machine includes a mold holding mechanism 1, a concave mold 2, a mold pushing mechanism 3, a plastic ejecting mechanism 4, a mold sending mechanism 5, a buffer mechanism 6, a return track 7, a pulling mechanism 8, a pulling mechanism Pipe mechanism 9, transmission mechanism 10, intubation mechanism 11, automatic unlocking mechanism 12, frame 13 and cooling system, wherein, frame 13 is the shelf of the hexahedron that is welded by square pipe and channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com