Overlength tube cold-drawing machine

A technology of cold drawing machine and pipe, which is applied in the direction of metal drawing forming tools, metal wire drawing, manufacturing tools, etc. It can solve the problems of heavy weight of roller chains, uneven drawing speed, affecting surface quality, etc., and achieve stable operation , reduce mutual friction, improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

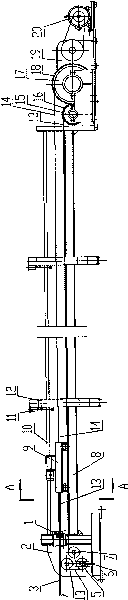

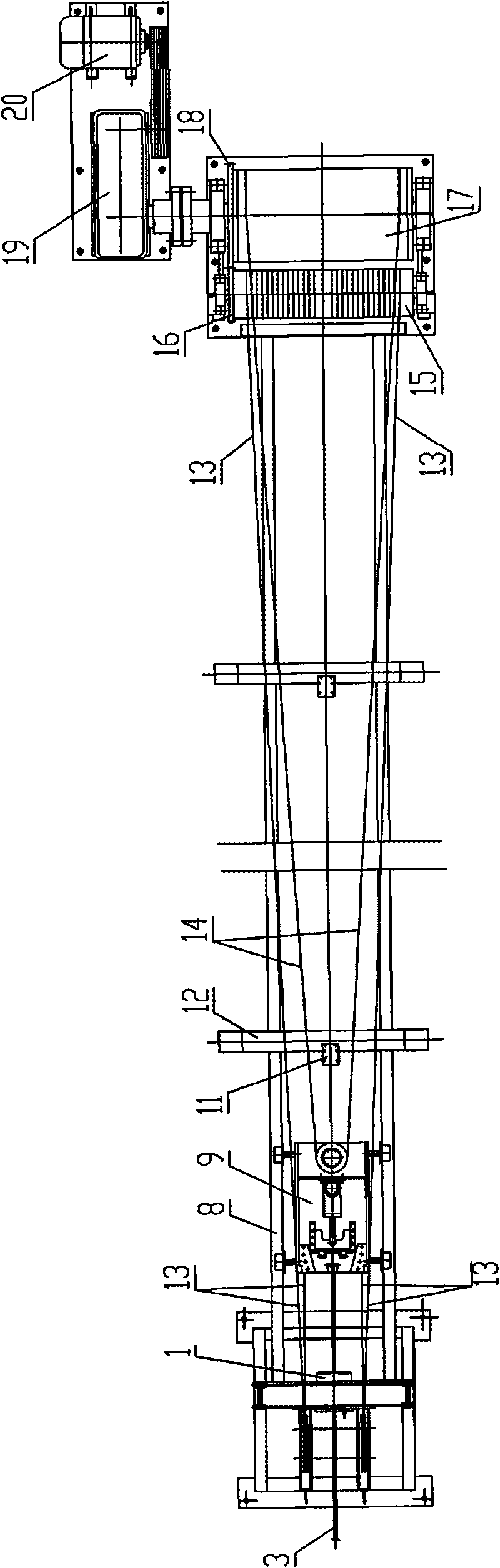

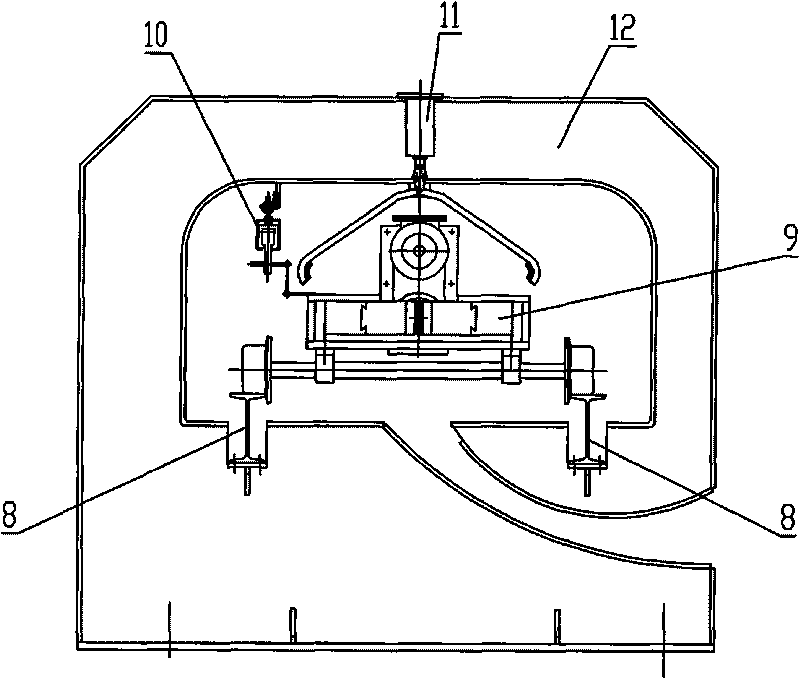

[0022] The structure of this embodiment is as figure 1 and figure 2 As shown, a super-long pipe cold drawing machine includes a drafting die 1 arranged on a head seat 2, a drawing trolley 9 that can move along a track 8 and a traction device connected to the drawing trolley 9. The traction device includes a The pulley block on the headstock 2, the motor 20 and the reducer 19 connected with the motor 20, the pulley block includes a fixed pulley 4, a movable pulley 5 and a fixed pulley 7; The adjusting lead screw 6 that the tension plays a regulating role, the thin steel wire rope 13 passes through one end of the fixed pulley 4 to connect the rear end of the drawing trolley 9, passes through the other end of the fixed pulley 7 and the small reel 15 located at the front end of the track 8 Connect, the front end of drawing trolley 9 is connected with the large reel 17 that is installed on small reel 15 sides by thick steel wire rope 14, and one end of small reel 15 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com