Multi-unit modularized plate type ozone generator

An ozone generator and multi-unit technology, which is applied in the direction of ozone preparation, chemical instruments and methods, and discharge method to prepare ozone, etc., can solve the problems of difficulty in further increasing ozone concentration, small single machine output, and affecting development, so as to improve ozone conversion efficiency , avoid too many connection points, avoid the effect of too many sealing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

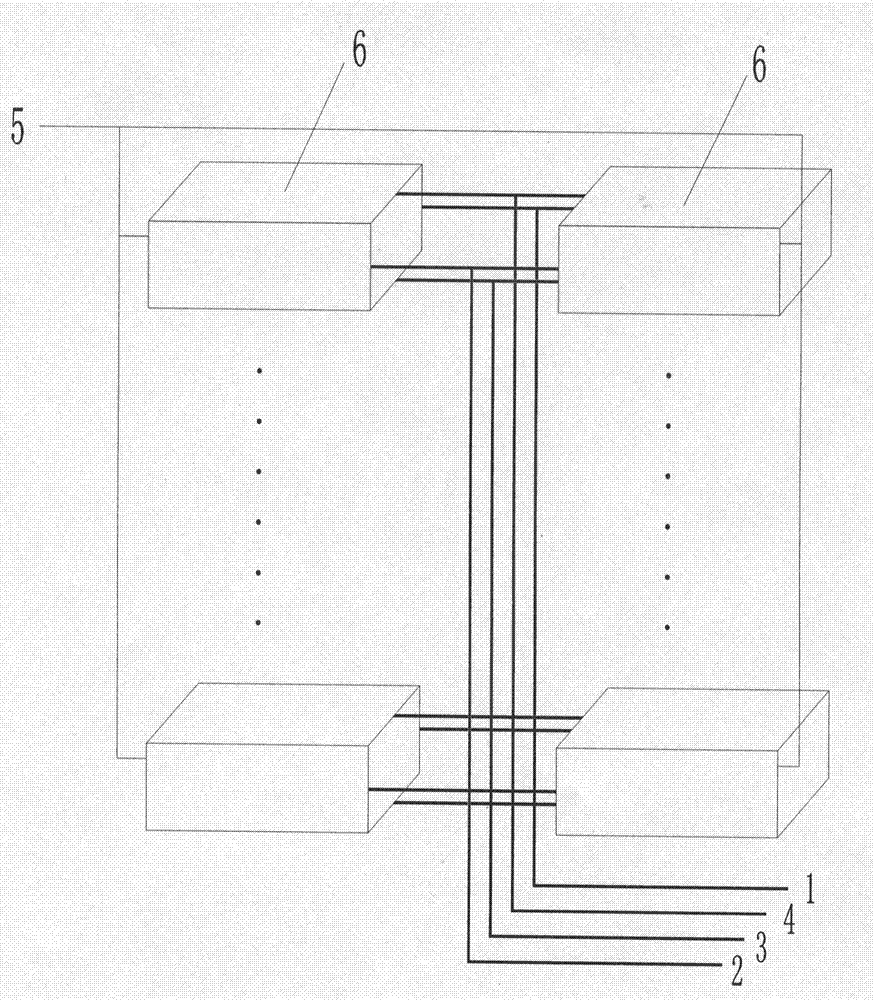

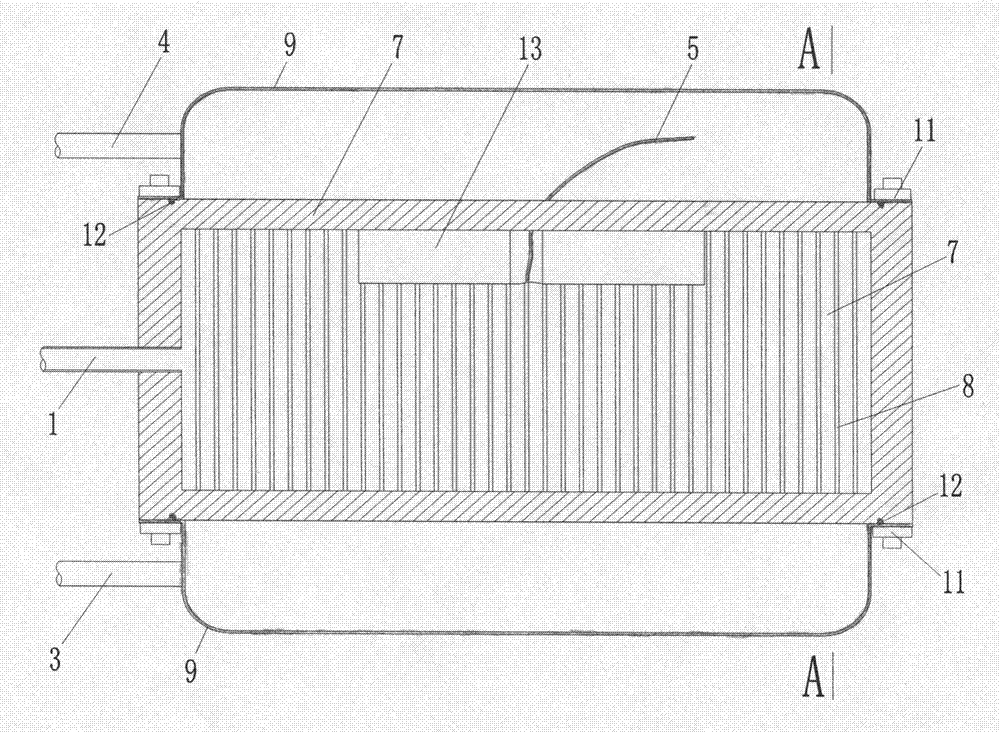

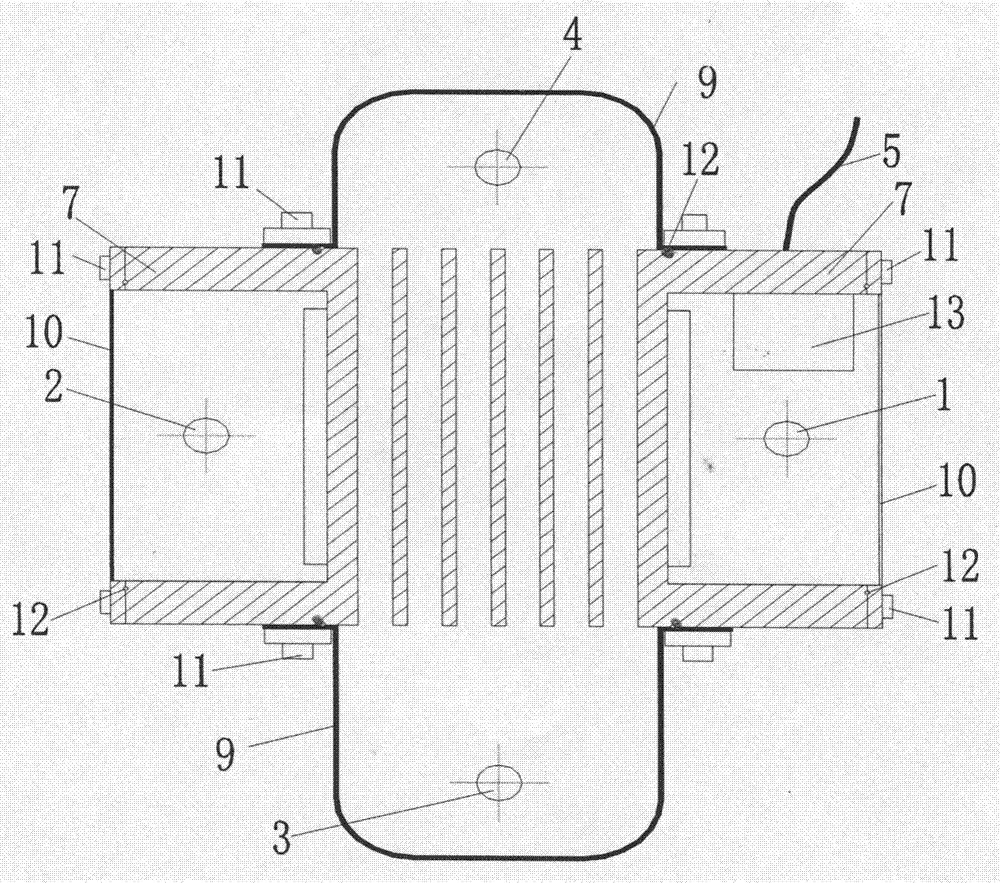

[0024] The multi-unit modular plate type ozone generator that the present invention proposes, its module structure is as follows figure 2 , image 3 As shown, there are two implementation methods.

[0025] One is to use a specially developed assembly platform to neatly place a certain number of discharge units 8 on the assembly platform and apply pressure evenly so that the holes on each ground electrode plate 14 in the discharge unit group are aligned with the holes on the two side plates 15. One-to-one correspondence, and then use welding or drawing tubes or hollow studs or cold drawing to assemble a group of ground electrode plates 14, two side plates 15 and two end plates 16 into a whole ground electrode frame 7, Such as Figure 4 , Figure 5 As shown, the sealing of the connection between the ground electrode plate 14 and the side plate 15, and the connection between the side plate 15 and the end plate 16 should be ensured, and the overall conductivity is good; an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com