Preparation technology for medical beta type titanium alloy capillary tubes

A preparation process and capillary technology, applied in the direction of temperature control, mandrel, etc., can solve the problems of medical β-type titanium alloy microcracks, high cost, low processing efficiency, etc., to achieve flexible production, low cost, and pass reduction big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation process of a medical β-type titanium alloy capillary, comprising the following steps:

[0034] Step 1, extruding to prepare the tube blank

[0035] The β-type medical titanium alloy ingot is prepared by vacuum consumable arc melting method, and then the titanium alloy ingot is forged and billeted into a round ingot, and then the round ingot is extruded into a tube billet on an extruder;

[0036] The diameter of the round ingot is Φ120-150mm, the diameter of the tube blank is Φ60-90mm, and the wall thickness is 10-30mm.

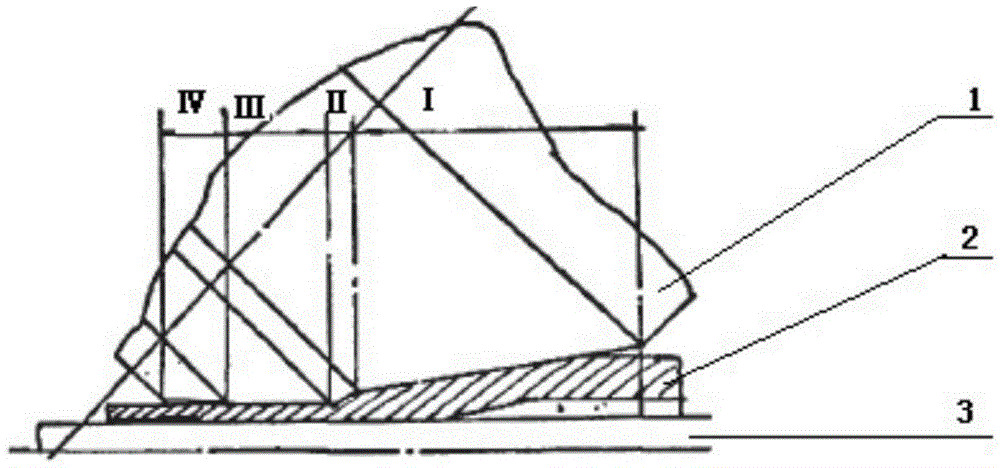

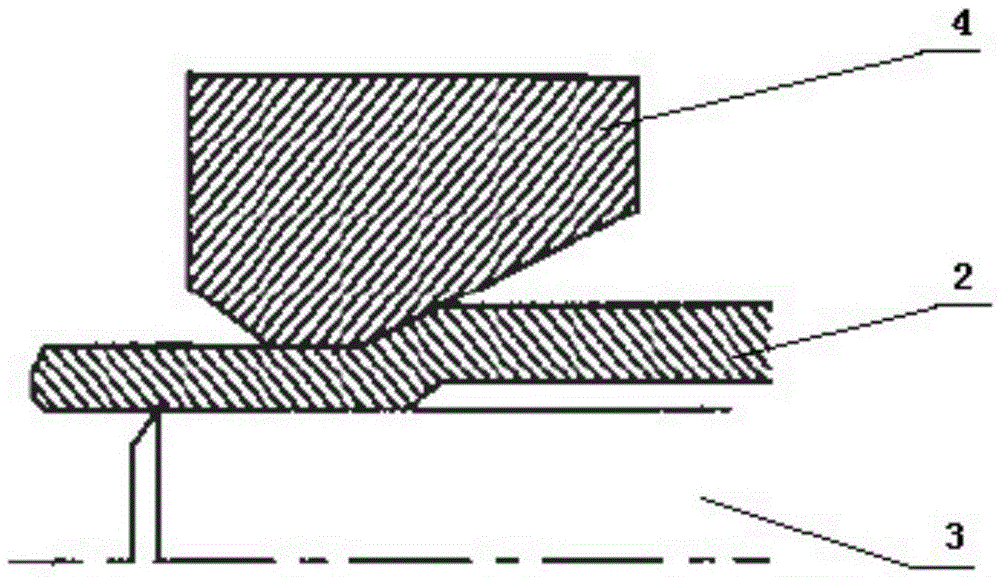

[0037] Step 2. Rolling and shrinking

[0038] The above-mentioned tube blank is rolled by a three-roll planetary rolling mill, and the tube blank is subjected to online induction heating during rolling, and the specific heating temperature value is determined by the material of the tube blank; the heating temperature is 800-1000°C.

[0039] The three-roller planetary rolling mill rolls the tube blank twice, and the first time rolls the t...

Embodiment 1

[0048] A β-type medical titanium alloy capillary with a composition of Ti-20Nb-3Zr was prepared.

[0049](1) Extrusion to produce tube blanks: Ti-20Nb-3Zr is smelted into titanium alloy ingots by vacuum consumable arc melting method. After forging and billeting, a round ingot with a diameter of Φ120mm is made, and the 1250-ton extrusion machine Extrude a tube blank with a diameter of Φ60mm and a wall thickness of 10mm, and polish the inside and outside.

[0050] (2) Rolling diameter reduction: The extruded Ti-20Nb-3Zr titanium alloy tube blank is rolled twice by a three-roller planetary rolling mill: the first rolling is to a tube blank with a diameter of Φ32mm and a wall thickness of 3mm; The second rolling is to a tube blank with a diameter of Φ12mm and a wall thickness of 1.5mm. The tube blank is heated by online induction during rolling. The heating temperature is 850°C. The rolling feed speed is 2m / min for the first time, and the second The time is 4m / min;

[0051] (3) ...

Embodiment 2

[0055] The β-type medical titanium alloy capillary with the composition of Ti-14Nb-5Ta was prepared.

[0056] (1) Extrusion to produce tube blanks: Ti-14Nb-5Ta is smelted into titanium alloy ingots by vacuum consumable arc melting method. After forging and billeting, a round ingot with a diameter of Φ140mm is made, and the 1250-ton extrusion machine Extrude a tube blank with a diameter of Φ70mm and a wall thickness of 15mm, and polish the inside and outside.

[0057] (2) Rolling diameter reduction: The extruded Ti-14Nb-5Ta titanium alloy tube billet is rolled twice by a three-roller planetary rolling mill: the first rolling is to a tube billet with a diameter of Φ35mm and a wall thickness of 3.5mm ; The second rolling is to a tube blank with a diameter of Φ15mm and a wall thickness of 1.8mm. During rolling, the tube blank is heated by online induction. The heating temperature is 900°C, and the rolling feed rate is 2.5m / min for the first time. The second time is 4.5m / min.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com