Automatic production line of light partition board

An automatic production line and lightweight partition board technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve problems such as low production efficiency, unstable product quality, and high labor intensity, and achieve high production efficiency, The effect of stable product quality and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

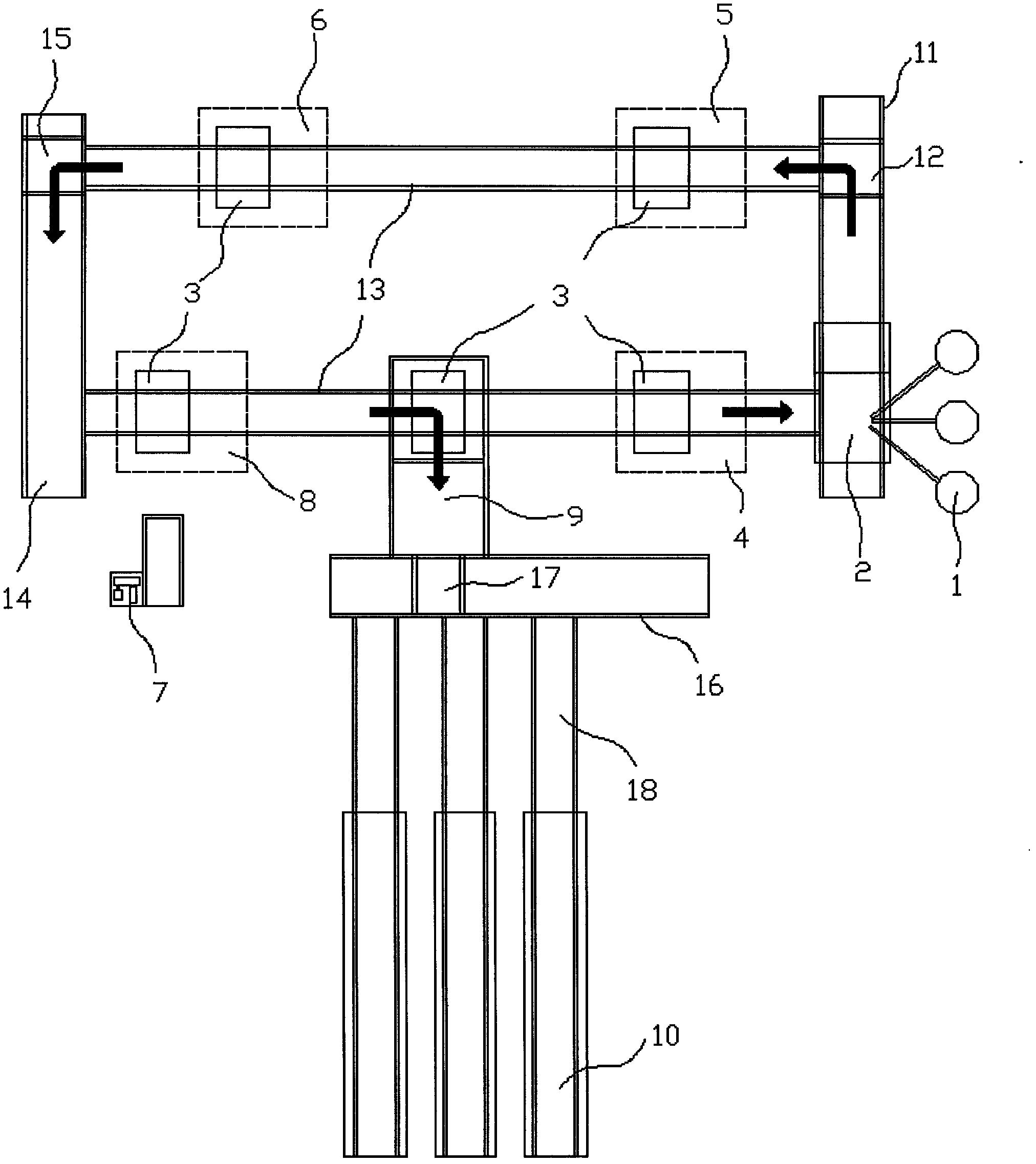

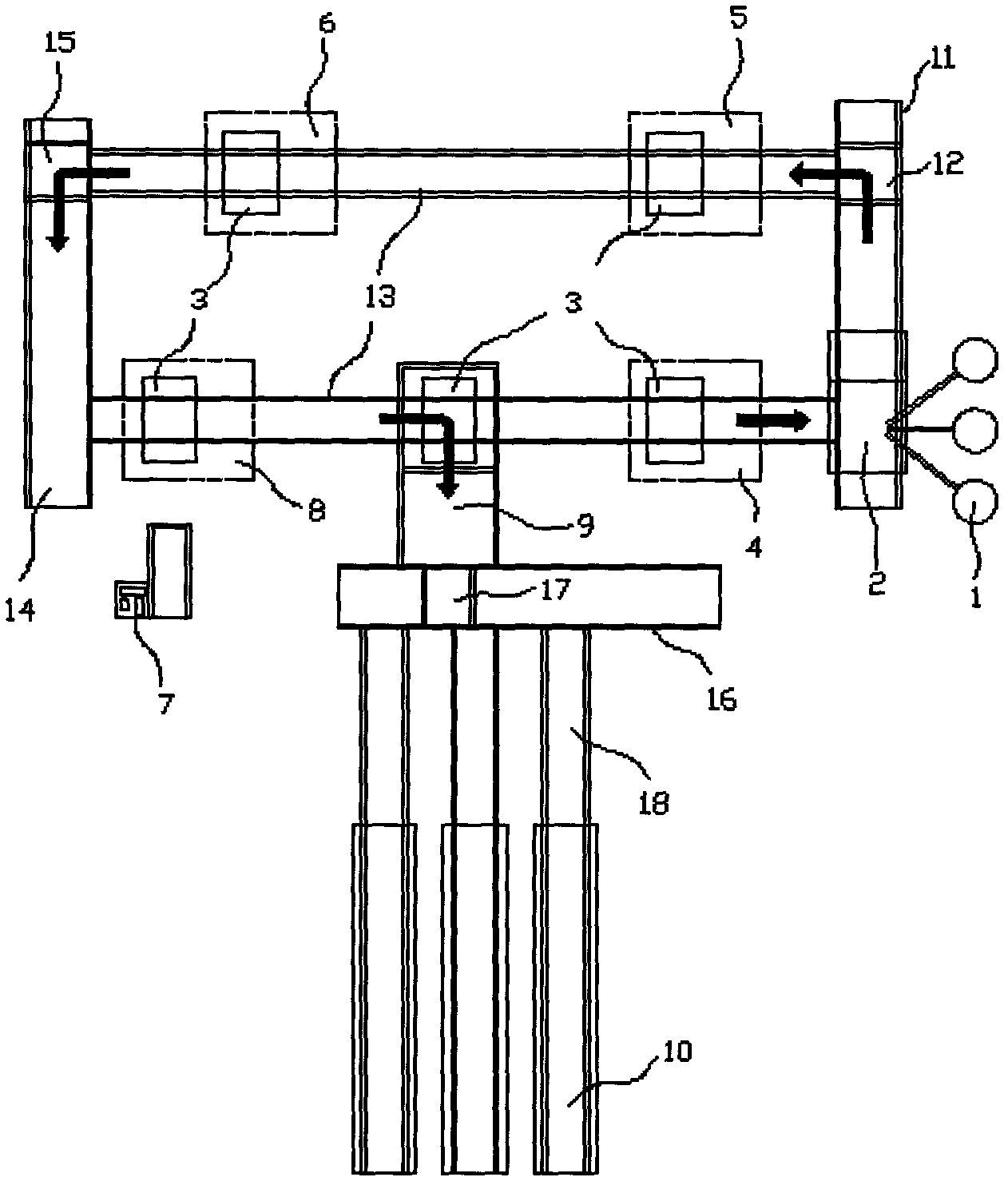

[0013] figure 1 It is an automatic production line for lightweight partition panels, which is composed of a material warehouse 1, a grouting device 2, a wall panel machine 3, a pipe loading machine, a winch 7, an autoclave 10, a hoisting machine, and a driving track and a ferry car. .

[0014] In the production area, the tracks 11, 13, and 14 laid parallel to each other form a circulating production flow line, and there are grouting area, pipe fitting area, curing forming area, solidification area, tube removal area, and hanging area near the track. Board area and other work areas. Among them, a material bin 1 and a grouting device 2 for batching are installed in the grouting area, a tube loading machine is installed in the tube loading and mold clamping area 4, a hoist 7 for tube pulling is installed in the tube pulling area 8, and a hoist 7 for tube pulling is installed in the hanging plate area 9 A hoisting machine is installed, and a plurality of wallboard machines 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com