Copper tube drawing internal film oil composition and its use

A composition and copper tube technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as insufficient annealing cleanliness of oil products, and achieve the effect of improving annealing cleanliness and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

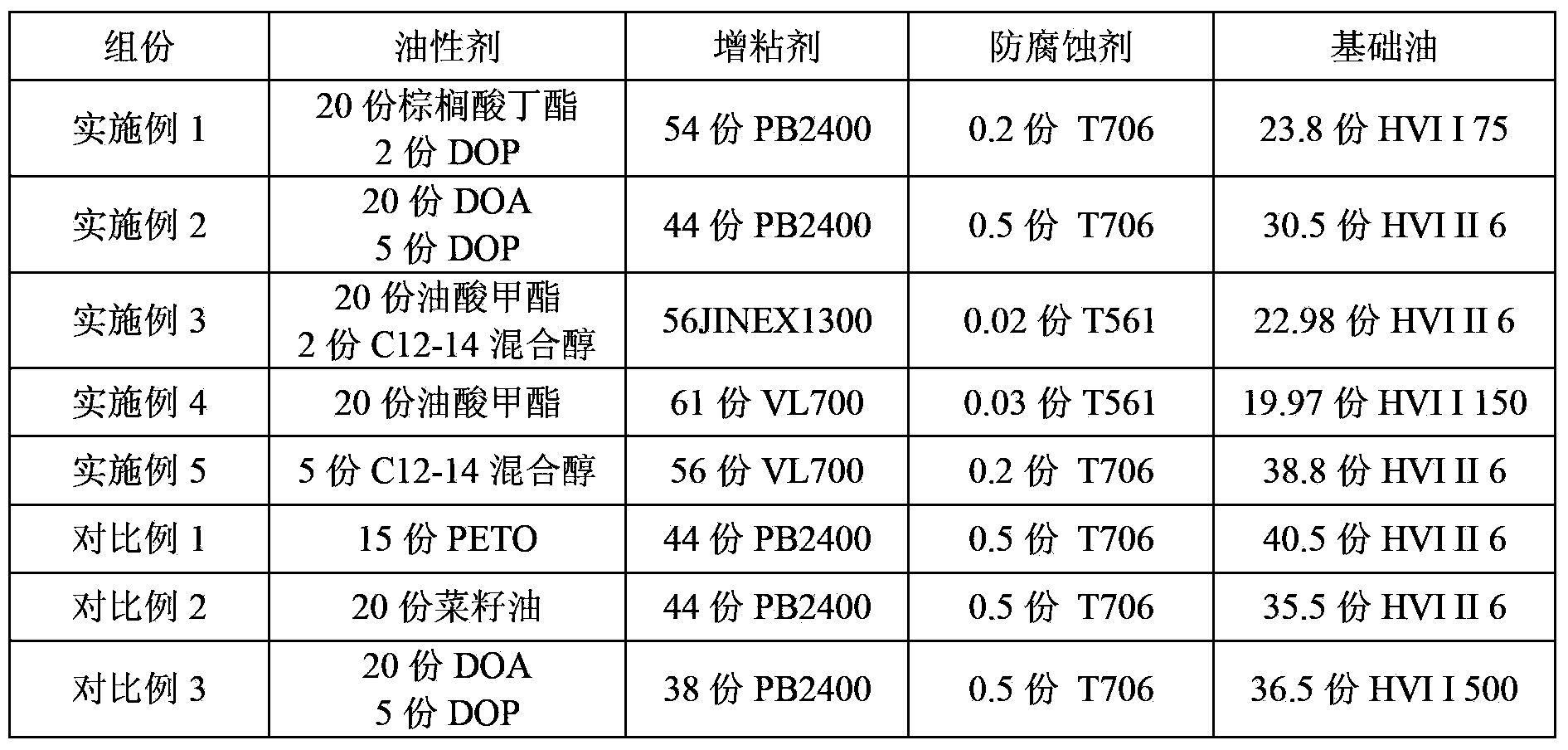

[0027] Mix the required amount of base oil, oily agent, tackifier, and anti-corrosion agent, heat to 60°C, stir at constant temperature for 60 minutes, and pack in cans after passing the inspection. Wherein each component and its parts by weight are shown in Table 1, and the product properties are shown in Table 2.

[0028] In Table 1, DOP is diisooctyl phthalate, DOA is dibutyl phthalate, PB2400 is polyisobutylene with molecular weight of about 2400, JINEX1300 is polyisobutylene with molecular weight of 1300, and VL700 is polyisobutylene with molecular weight of 100000. ethylene propylene rubber, T706 is benzotriazole, T561 is thiadiazole derivatives, HVI I75, HVI I150 are solvent refined mineral oil, HVI II6 is hydrogenated refined mineral oil.

[0029] HVI I75 has a kinematic viscosity of 15mm at 40°C 2 / s, the kinematic viscosity of HVI I150 at 40°C is 30mm 2 / s, HVI II6 has a kinematic viscosity of 30mm at 40°C 2 / s.

[0030] In Table 2, PB is the maximum non-seizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com