Glass tube drawing machine

A tube drawing machine and glass tube technology, applied in glass production, glass forming, glass reshaping, etc., can solve the problems affecting the glass tube drawing tube forming, reducing the yield, glass tube twisting, etc., to avoid twisting, Improve yield rate and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

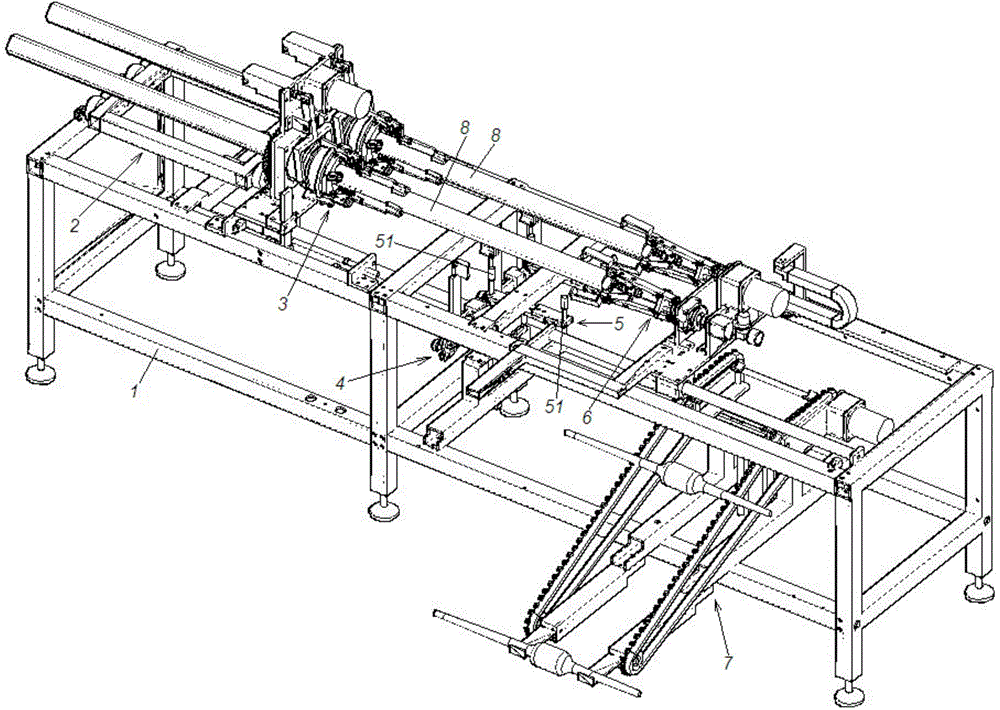

[0027] figure 1 A glass drawing machine according to an embodiment of the present invention is schematically shown.

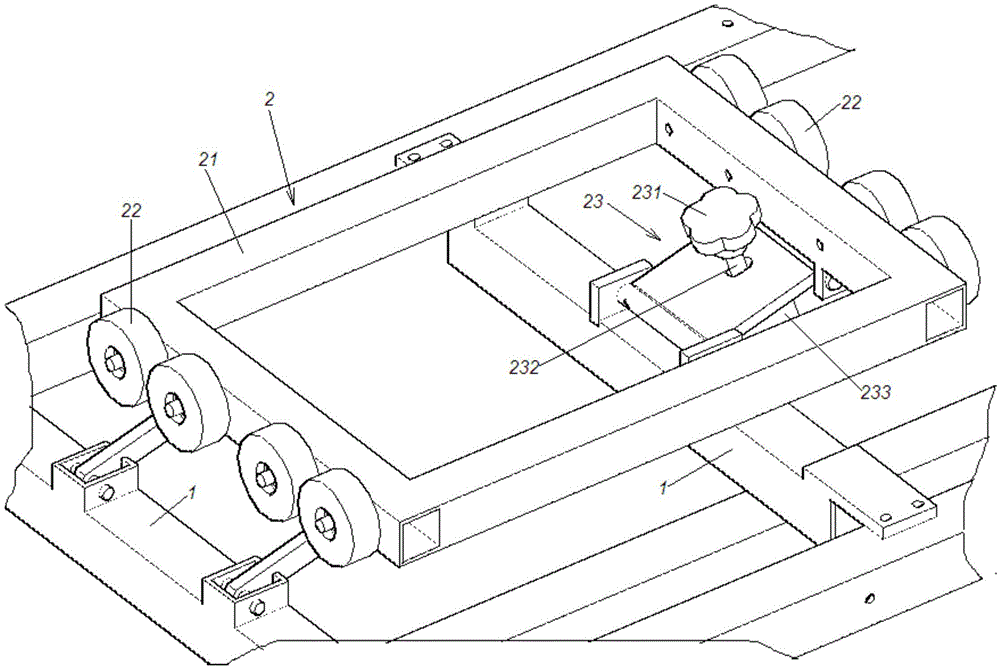

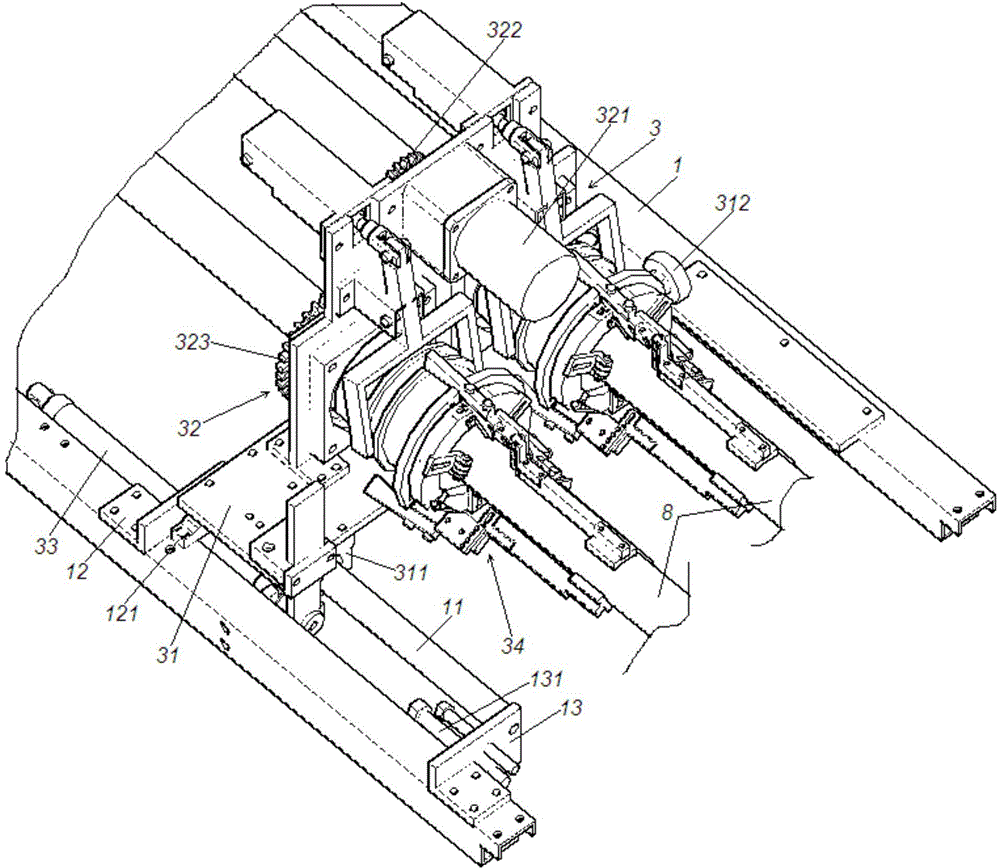

[0028] Such as figure 1 As shown, the glass tube drawing machine includes a frame 1, a supporting mechanism 2, a tube feeding mechanism 3, a tube clamping mechanism 4, a flame spraying device 5, a tube pulling mechanism 6 and a tube discharging mechanism 7. In order to improve the processing efficiency, the frame 1 is equipped with two sets of the same tube feeding mechanism 3, tube clamping mechanism 4 and tube pulling mechanism 6, which can simultaneously process two glass tubes 8, and can process glass tubes with a diameter of 55mm to 95mm. Glass tube8. The supporting mechanism 2 and the pipe outlet mechanism 7 are installed on the head and tail ends of the frame 1 respectively. The tube feeding mechanism 3 and the tube pulling mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com