Hydraulic cold drawn pipe machine

A pipe extruding machine and hydraulic technology, which is applied in the field of metal pipe cold drawing equipment, can solve the problems of high compressive strength and rigidity requirements, and achieve the effects of low cost, overcoming lateral movement and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

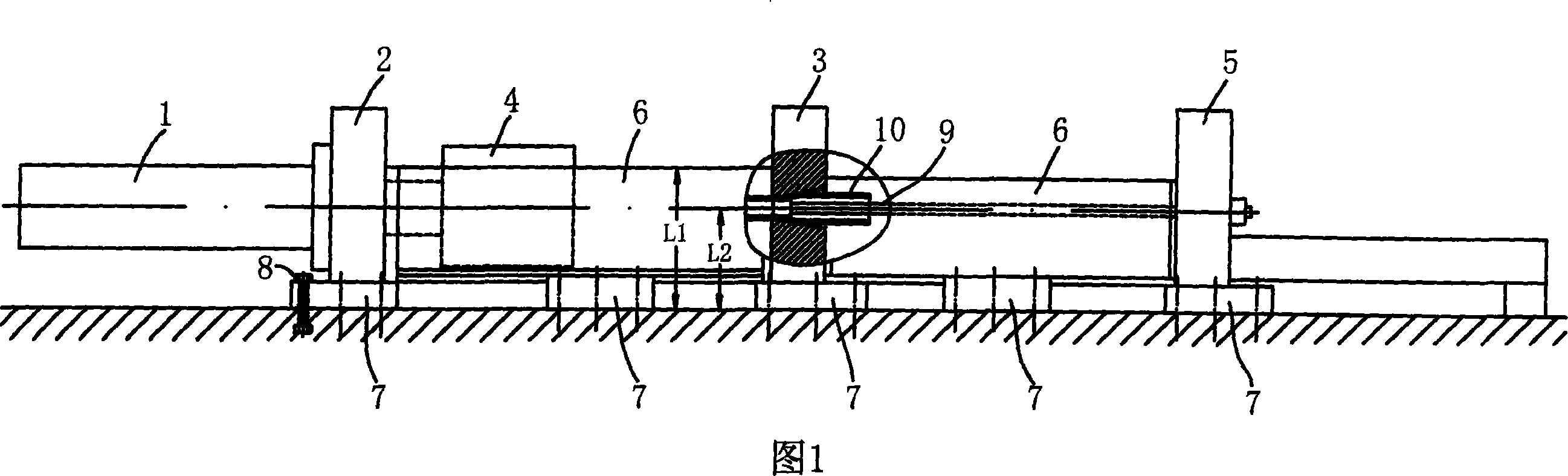

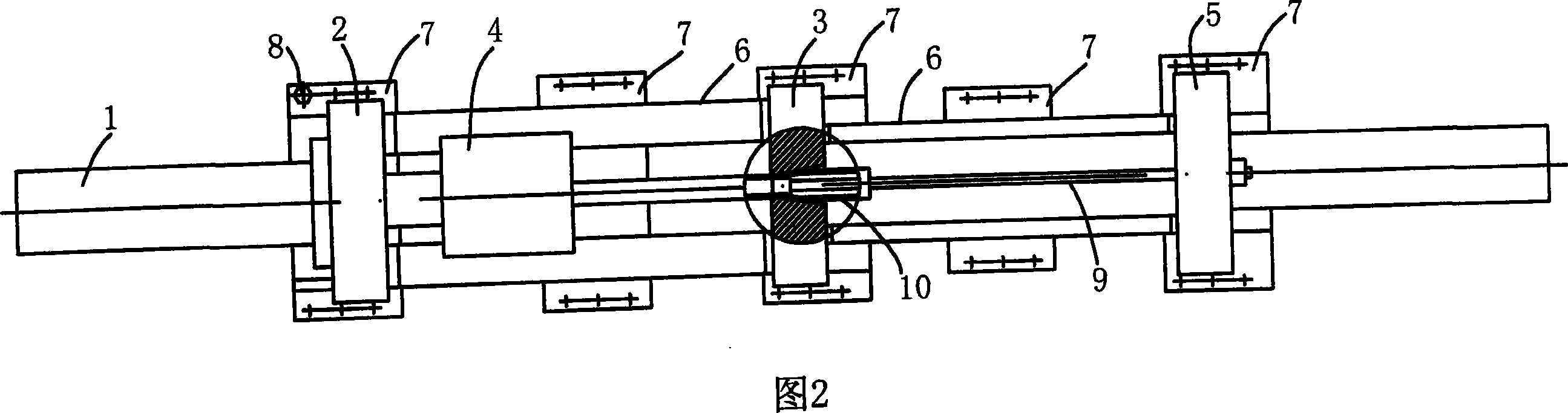

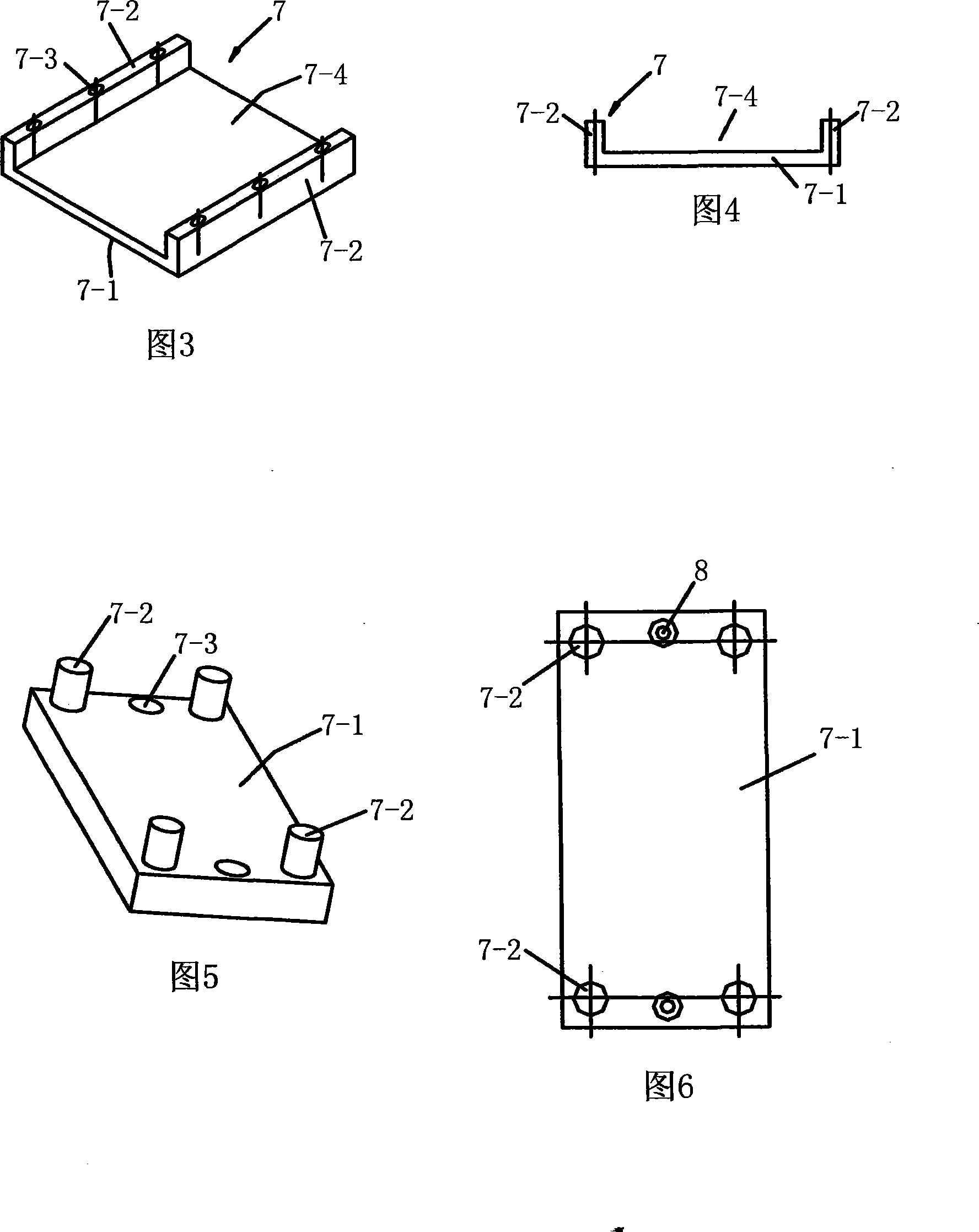

[0028] The accompanying drawings disclose the specific structures of the embodiments of the present invention, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] It can be seen from Fig. 1 and Fig. 2 that the hydraulic cold drawn pipe machine includes a main cylinder seat 2 for installing the main cylinder 1, and a drawing die seat 3 inside which can draw the drawn pipe blank 10 into a forming mold, and Located between the main cylinder base 2 and the drawing die base 3, there is a clamp trolley 4 driven by the main cylinder 1 and used to clamp the drawn tube blank 10, and the end is provided for penetrating The core rod seat 5 of the positioning core rod 9 is fixedly connected with two segmented independent bed bodies 6 between the main cylinder seat 2, the drawing die seat 3 and the core rod seat 5, the main oil cylinder seat 2, the drawing die The seat 3, the clamp trolley 4, the mandrel seat 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com