Early-strength type cement-based grouting material and using method thereof

A technology of cement-based and grouting material, applied in the field of cement-based grouting material, can solve the problems of high cost, poor fluidity, failure to meet architectural design standards, etc., and achieve the effect of high fluidity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

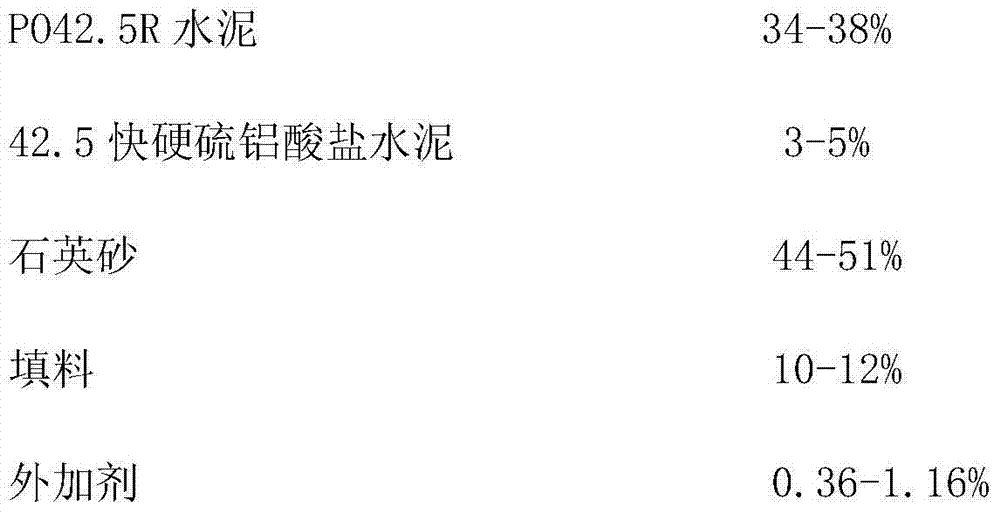

[0019] An early-strength cement-based grouting material, the mass percentage of its components is as follows:

[0020]

[0021]

[0022] How to use: Put the weighed raw materials in a forced mixer and mix them evenly, then pack them into bags, and then transport them to the construction site after passing the inspection. Add water according to the water-material ratio of 0.15:1, and measure the basic performance:

[0023] Initial fluidity 355mm, 30min fluidity 315mm, 24h compressive strength 27.2MPa, 3d compressive strength 50.4MPa, 28d compressive strength 75.4MPa, 1d vertical expansion rate 0.08%, bleeding rate 0%, in line with JC / T986- The requirements stipulated in the 2005 cement-based grouting material standard.

Embodiment 2

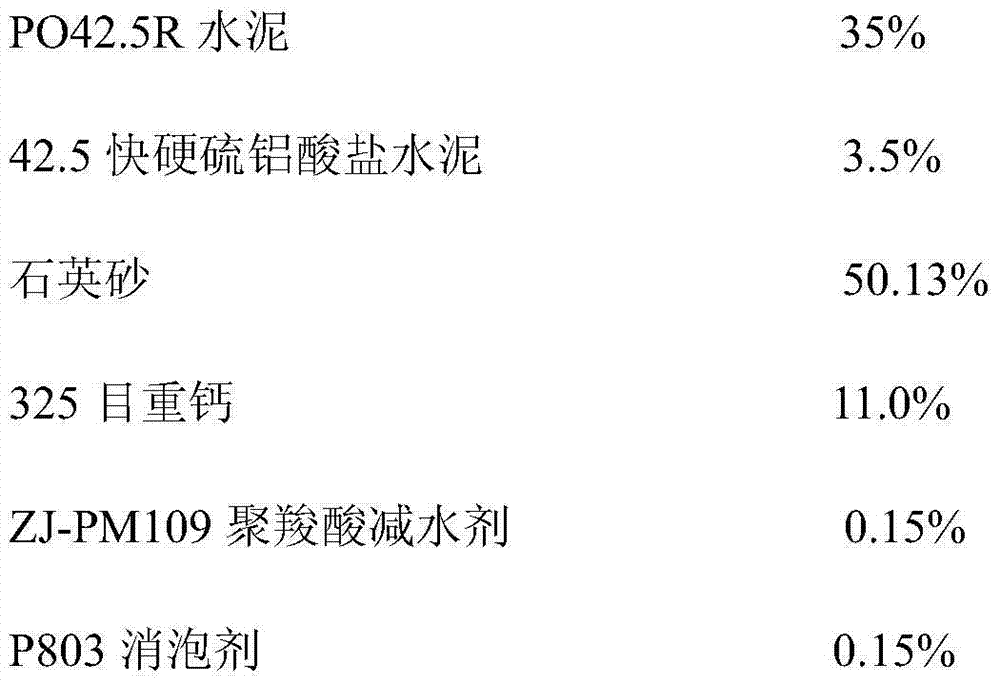

[0025] An early-strength cement-based grouting material, the mass percentage of its components is as follows:

[0026]

[0027] How to use: Put the weighed raw materials in a forced mixer and mix them evenly, then pack them into bags, and then transport them to the construction site after passing the inspection. Add water according to the water-material ratio of 0.15:1, and measure the basic performance:

[0028] Initial fluidity 345mm, 30min fluidity 305mm, 24h compressive strength 29.3MPa, 3d compressive strength 54.1MPa, 28d compressive strength 77.4MPa, 1d vertical expansion rate 0.06%, bleeding rate 0%, in line with JC / T986- The requirements stipulated in the 2005 cement-based grouting material standard.

Embodiment 3

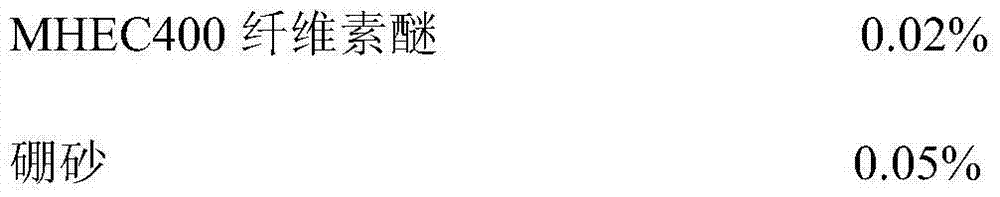

[0030] An early-strength cement-based grouting material, the mass percentage of its components is as follows:

[0031]

[0032] How to use: Put the weighed raw materials in a forced mixer and mix them evenly, then pack them into bags, and then transport them to the construction site after passing the inspection. Add water according to the water-material ratio of 0.15:1, and measure the basic performance:

[0033] Initial fluidity 350mm, 30min fluidity 300mm, 24h compressive strength 30.3MPa, 3d compressive strength 56.1MPa, 28d compressive strength 81.4MPa, 1d vertical expansion rate 0.05%, bleeding rate 0%, in line with JC / T986- The requirements stipulated in the 2005 cement-based grouting material standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com