Construction method of thermal insulation buildings roof of foam glass

A foam glass, thermal insulation technology, applied in the direction of building roofs, roof cladding, roof insulation materials, etc., can solve the problems of short service life, poor fireproof performance of insulation materials, and affecting the performance of insulation layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

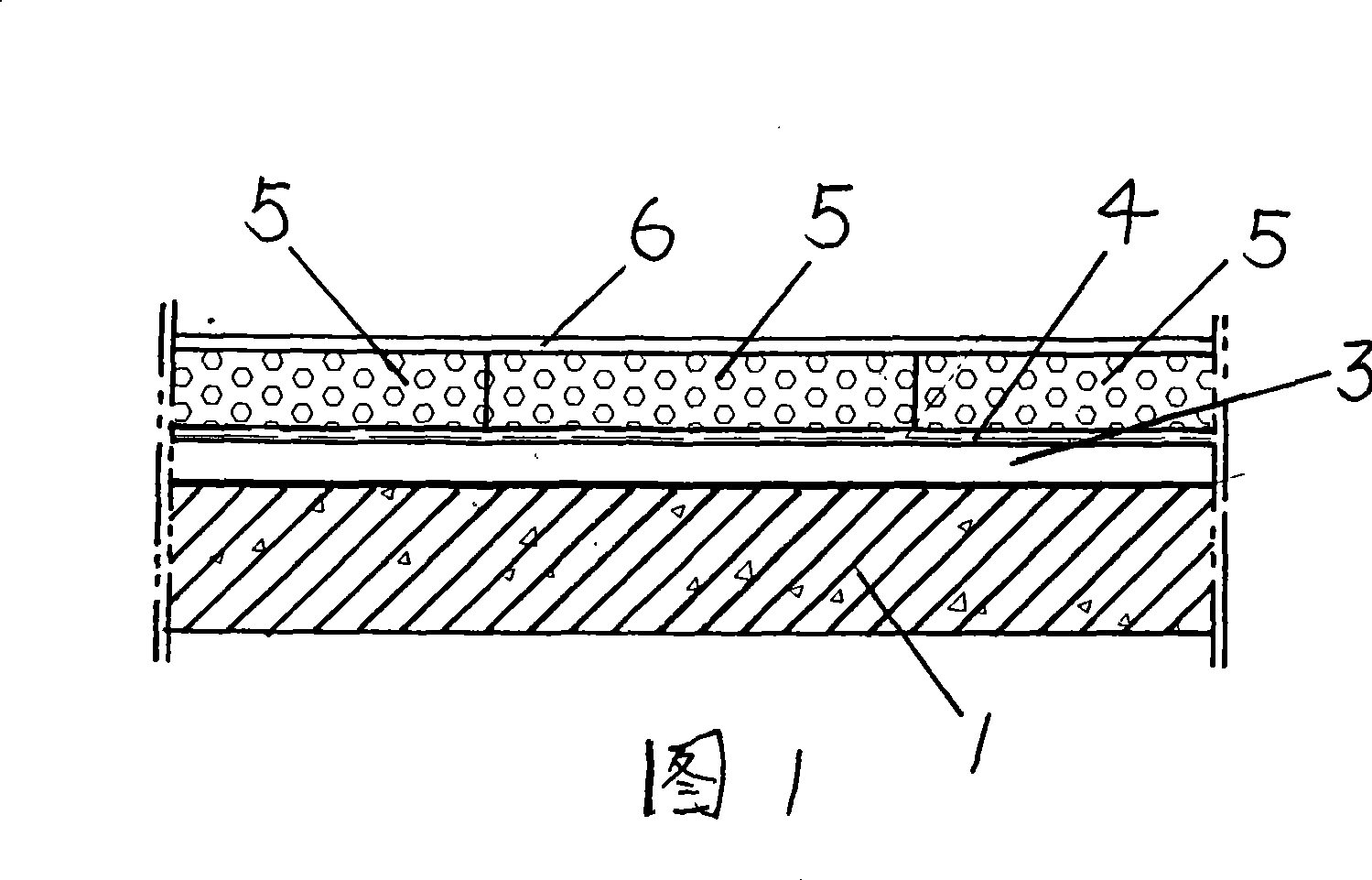

[0007] Embodiment 1: With reference to Fig. 1. This embodiment is a construction method of laying a layer of insulation board on the roof of a building that is a sloped roof or a tiled roof. Firstly, a leveling layer is poured on the sloped roof or tiled roof of the building, then a waterproof layer and a layer of insulation board are laid on the leveling layer in turn, and finally a protective layer is poured on the insulation board. The purpose of the invention of the present invention can be realized because the insulation board adopts the foam glass insulation board.

Embodiment 2

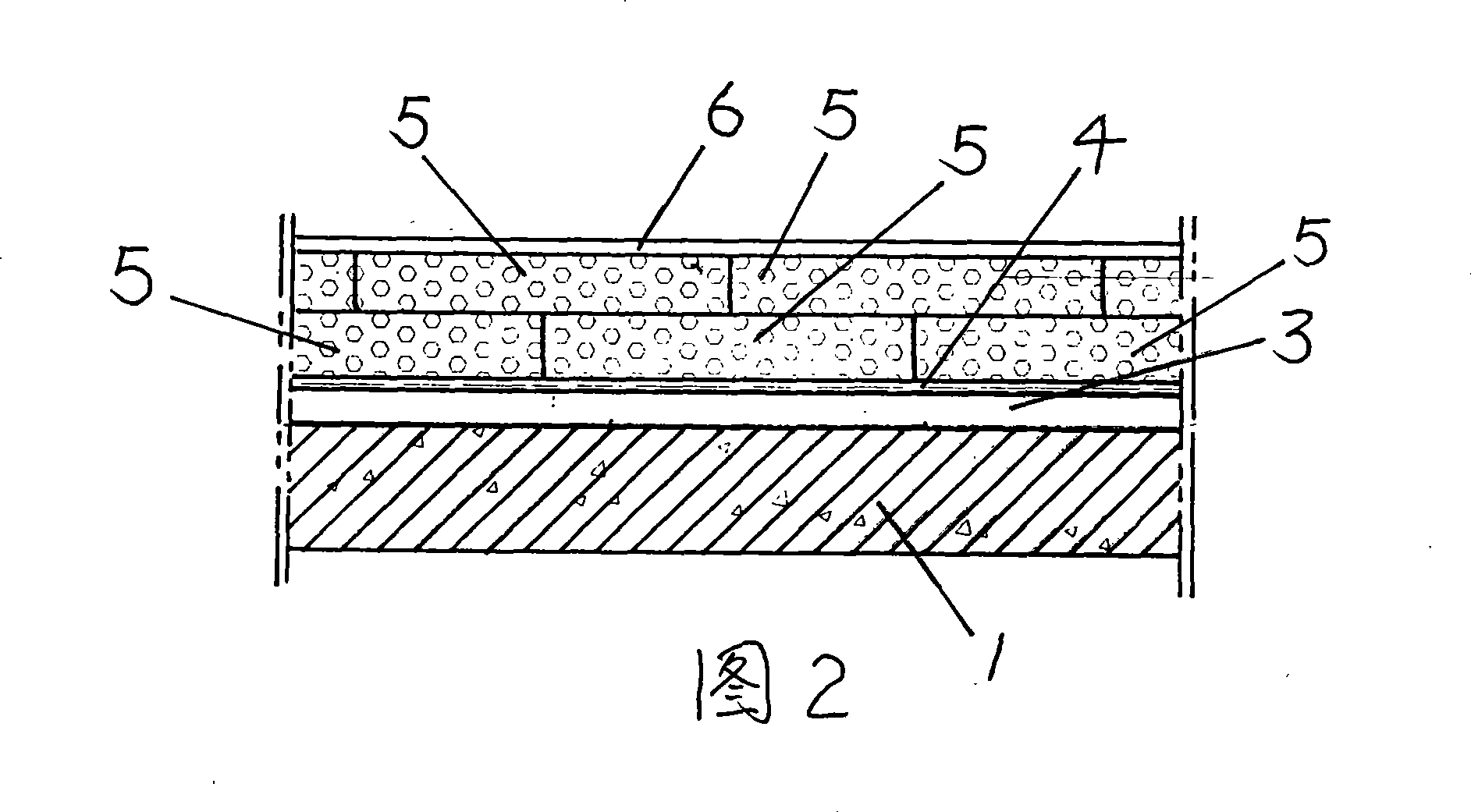

[0008] Embodiment 2: with reference to Fig. 2. This embodiment is a construction method of laying two layers of thermal insulation boards on a building roof that is a sloping roof or a tiled roof. This embodiment is on the basis of embodiment 1, except laying two layers of insulation boards, all the other implementation steps are the same as embodiment 1.

Embodiment 3

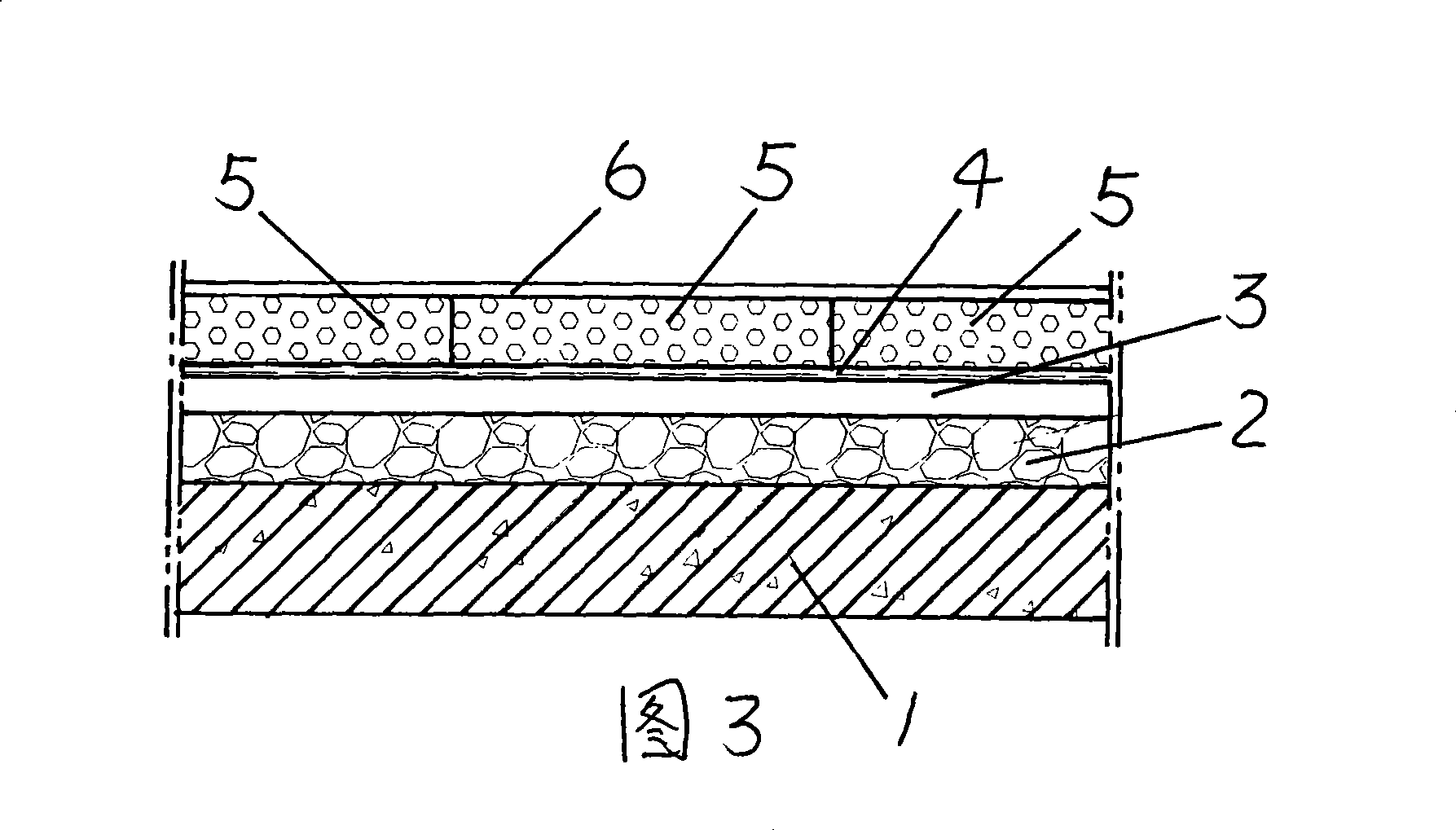

[0009] Embodiment 3: With reference to Fig. 3. This embodiment is a construction method of laying a layer of thermal insulation board on the roof of a building that is a flat roof or a raised roof, a planted roof, and a basement roof (roof) with thermal insulation requirements. Firstly pour the slope layer and leveling layer on the flat roof or overhead roof, planting roof, and basement roof (roof) with thermal insulation requirements, and then lay a waterproof layer and a layer of insulation board on the leveling layer in sequence , and finally pour a protective layer on the insulation board. The purpose of the invention of the present invention can be realized because the insulation board adopts the foam glass insulation board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com