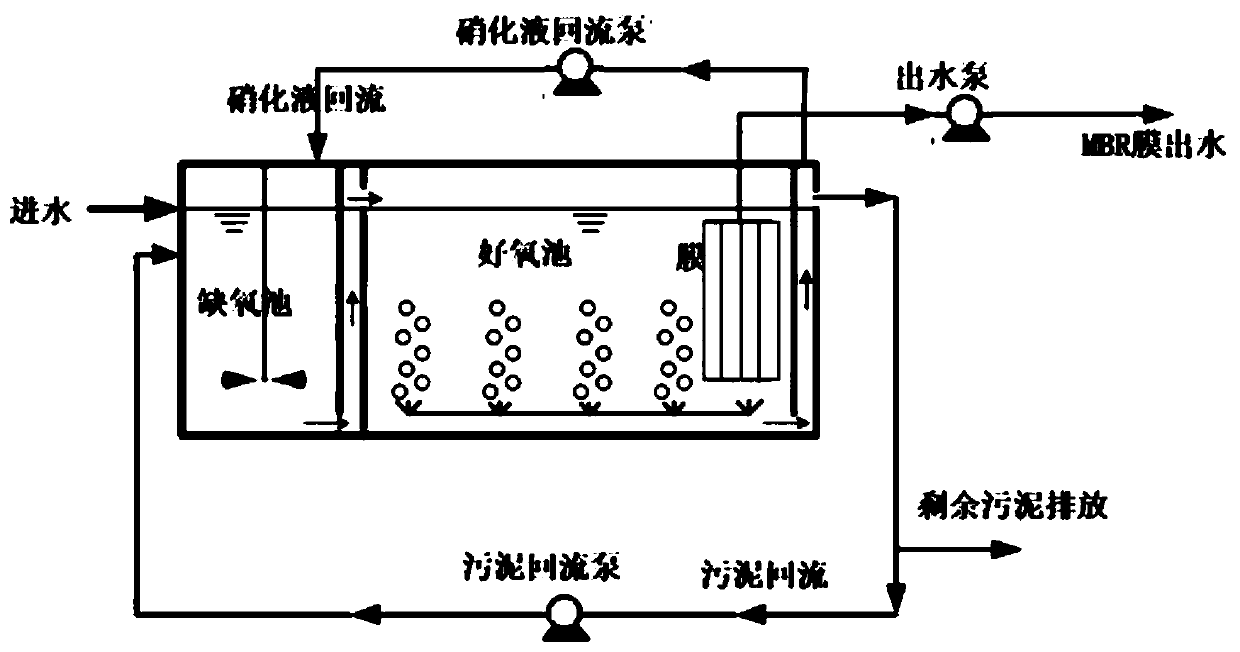

Device and method for in-situ sludge reduction by intensive AOMBR (anoxic/aerobic membrane bioreactor) process

A sludge in-situ reduction and process technology, applied in the field of sewage treatment, can solve the problems of high operating energy consumption and infrastructure costs, increased energy consumption and operating costs, and large capacity of sludge storage tanks, etc., to achieve enhanced sludge attenuation Phenomenon, energy saving, enhanced effect of dissimilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The experimental sludge was taken from the activated sludge of the aerobic pool of Zigong City Wastewater Treatment Plant, and the concentration of the inoculum sludge was 5000-6000mg / L.

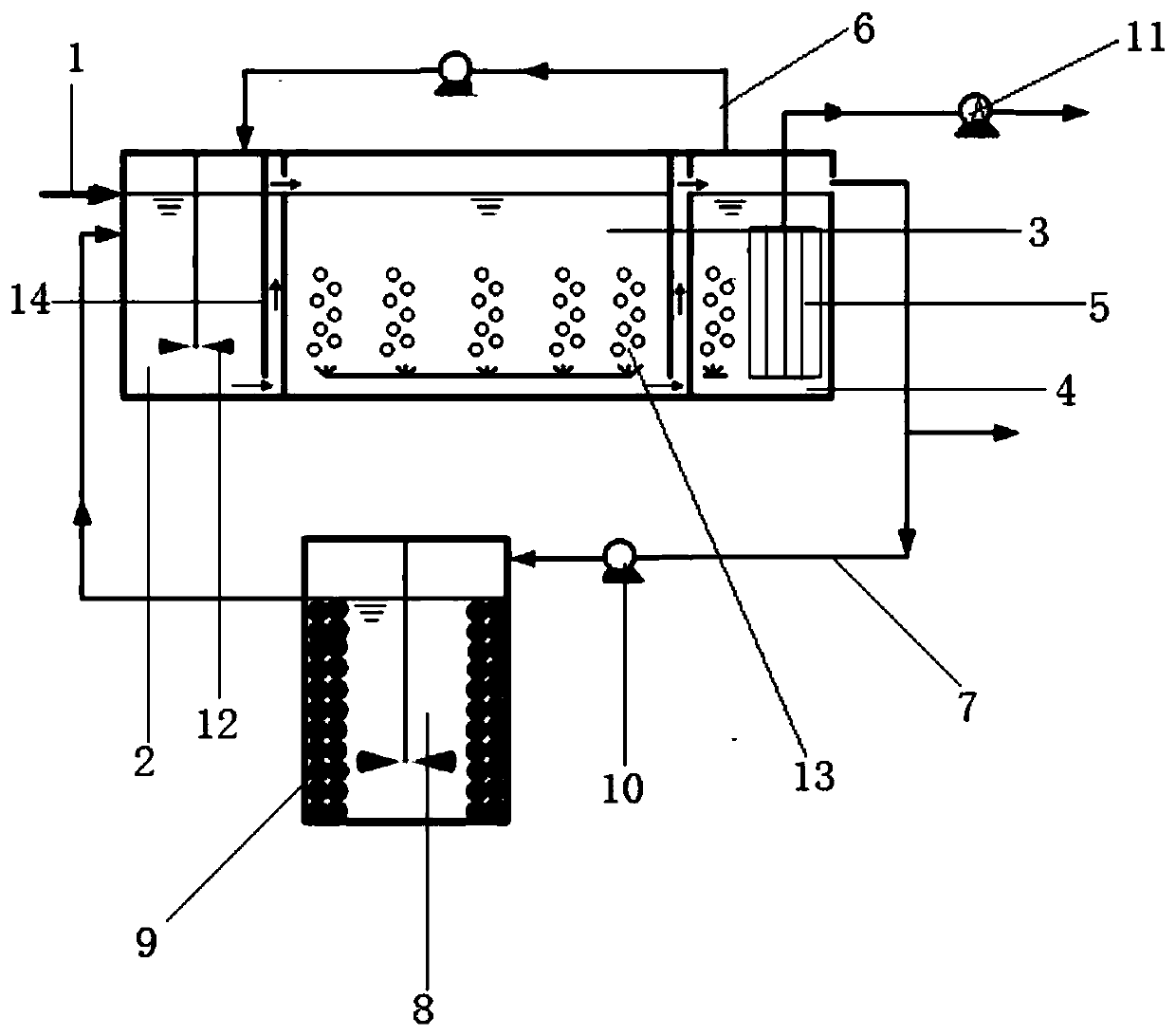

[0037] The present invention a kind of technology that strengthens the in-situ reduction of AOMBR process sludge, such as figure 2 As shown, the following steps are included: the sewage enters the anoxic tank 2 through the water inlet 1, and the sewage and the sludge are fully mixed through the action of the mechanical agitator 12, and part of the granular, colloidal, and dissolved carbon sources in the raw sewage It is hydrolyzed and acidified by the action of microbial flora, and converted into easily biodegradable small molecular substances, and then the mixed solution degraded by the anoxic pool 2 passes through the partition baffle 14 between the anoxic pool 2 and the aerobic pool 3, and is formed by the anoxic pool 2. The bottom of the oxygen tank 2 enters the upper part of the...

Embodiment 2

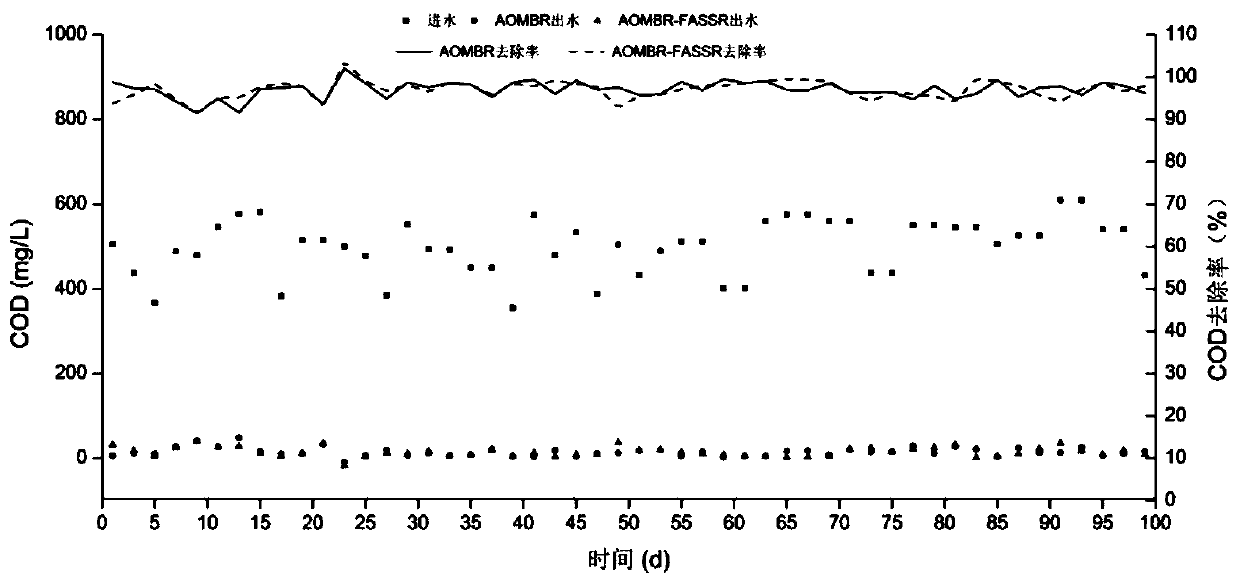

[0040] The experimental sludge was taken from the activated sludge of the aerobic pool of Zigong City Wastewater Treatment Plant, and the concentration of the inoculum sludge was 5000-6000mg / L. Attached figure 2 Device, set the dissolved oxygen in the anoxic tank to be controlled at 0.3mg / L, the DO in the aerobic tank to be controlled at 3.0mg / L, the dissolved oxygen in the side stream anaerobic reactor to be lower than 0.1mg / L, and the dissolved oxygen in the membrane tank to be controlled at 7mg / L; the flow rate of water controlled by the peristaltic pump is 49L / d. Influent water quality is chemical oxygen demand (COD) concentration 500mg / L; ammonia nitrogen (NH4+-N) content 55mg / L; total nitrogen (TN) content 70mg / L, total phosphorus (TP) content 4.5mg / L.

Embodiment 3

[0042] The experimental sludge was taken from the activated sludge of the aerobic pool of Zigong City Wastewater Treatment Plant, and the concentration of the inoculum sludge was 5000-6000mg / L. Attached figure 2 Device, set the dissolved oxygen in the anoxic tank to be controlled at 0.5mg / L, the DO in the aerobic tank to be controlled at 3.5mg / L, the dissolved oxygen in the side stream anaerobic reactor to be lower than 0.1mg / L, and the dissolved oxygen in the membrane tank to be controlled at 8mg / L; the flow rate of water controlled by the peristaltic pump is 49L / d. The influent water quality is as follows: chemical oxygen demand (COD) concentration 600mg / L; ammonia nitrogen (NH4+-N) content 60mg / L; total nitrogen (TN) content 75mg / L, total phosphorus (TP) content 5mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com