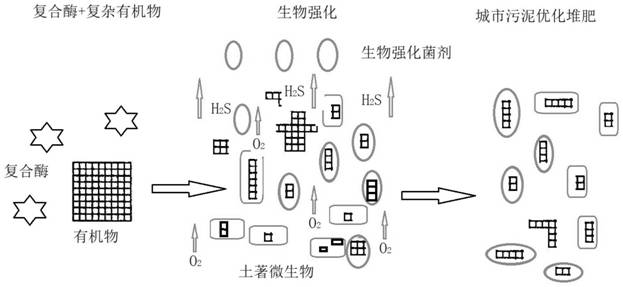

Method for optimizing rapid composting of municipal sludge through combination of enzymolysis pretreatment and biological enhancement

A technology that combines biological and municipal sludge, applied in the field of solid waste recycling, to achieve the effect of quick start-up of the reactor and obvious effect of nitrogen retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

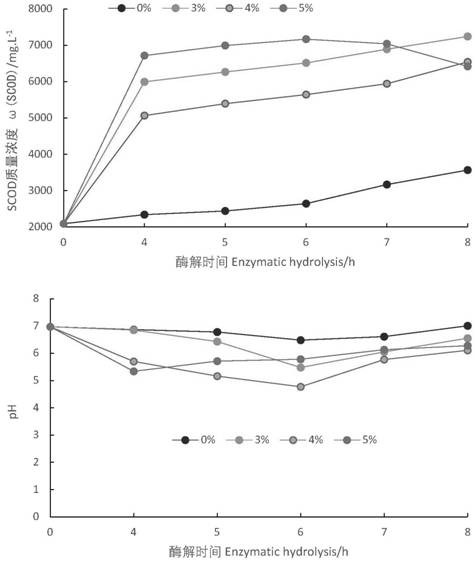

[0041] Compound enzyme hydrolysis pretreatment sludge process:

[0042] Place the remaining sludge of urban sewage treatment plants in a fermentation device for compound enzyme hydrolysis. The compound enzymes include lysozyme: protease: amylase: cellulase in a ratio of 1:1:1:1, and the addition ratio is 3%, 4%. and 5%. Insulate at 45°C, seal and let stand for hydrolysis for 4-8 hours. According to SCOD and pH, the added amount of compound enzyme was determined to be 4%, and the hydrolysis time was 6 hours. Under the same conditions, municipal sludge was anaerobically hydrolyzed as a control.

[0043] Biofortified and mixed material aerobic composting:

[0044] Mix 300mL HS-DO per kg reed stalk powder.

[0045] The pretreated municipal sludge and (reed stalk powder+HS-DO) are mixed according to the mass ratio of wet basis 2kg:500g to obtain the mixed material. The moisture content of the material is 65-70%, and the carbon-nitrogen ratio is 21-25. In the control, reed sta...

Embodiment 2

[0050] Biofortified and mixed material aerobic composting:

[0051] Mix 150mL HS-DO and 150mL phosphate buffer (pH 6.61) per kg reed stalk powder.

[0052] The pretreated municipal sludge and (reed stalk powder+HS-DO) are mixed according to the mass ratio of wet basis 2kg:500g to obtain the mixed material. The moisture content of the material is 65-70%, and the carbon-nitrogen ratio is 21-25. In the control, reed stalk powder was mixed in the same proportion without bioaugmentation.

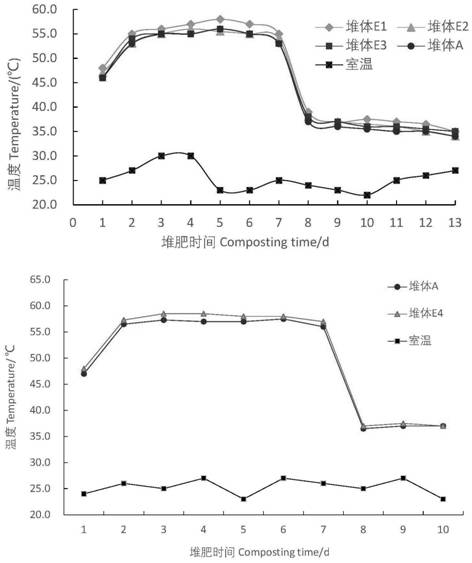

[0053] Aerobic composting includes three periods: start-up period for 1 day, heat preservation at 45°C; high temperature period for 6 days, temperature ≧50°C; natural decomposition for 6 days.

[0054] The total nitrogen content of the optimized compost product is 39.27mg·g -1 OM, increased by 33.46% compared with the initial stage, compared with the control (34.32mg·g -1 OM) increased by 14.41%, which has a certain nitrogen fixation effect. The cumulative release of ammonia and hydrogen su...

Embodiment 3

[0056] Biofortified and mixed material aerobic composting:

[0057] Mix the pretreated municipal sludge and reed stalk powder according to the wet basis mass ratio of 2kg:500g to obtain the mixed material. The moisture content of the material is 65-70%, and the carbon-nitrogen ratio is 21-25. In the control, reed stalk powder was mixed in the same proportion without bioaugmentation.

[0058] Aerobic composting includes three periods: start-up period for 1 day, heat preservation at 45°C; high temperature period for 6 days, temperature ≧50°C; natural decomposition for 6 days.

[0059] Spray the surface liquid after turning the pile every day. Mainly concentrated in the first four days.

[0060] The total nitrogen content of the optimized compost product is 39.11 mg·g -1 OM increased by 32.91% compared with the initial stage, and increased by 13.93% compared with the control (p-3 , respectively compared with the control 672.86mg·m -3 and 167.09 mg·m -3 A reduction of 22.83%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com