Preparation process of lysine fermentation culture medium

A lysine fermentation and preparation technology, applied in the direction of fermentation, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high cost of fermentation medium and low yield of lysine, and achieve easy enzymatic hydrolysis , low cost, and the effect of increasing the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A lysine fermentation medium, which comprises the following components:

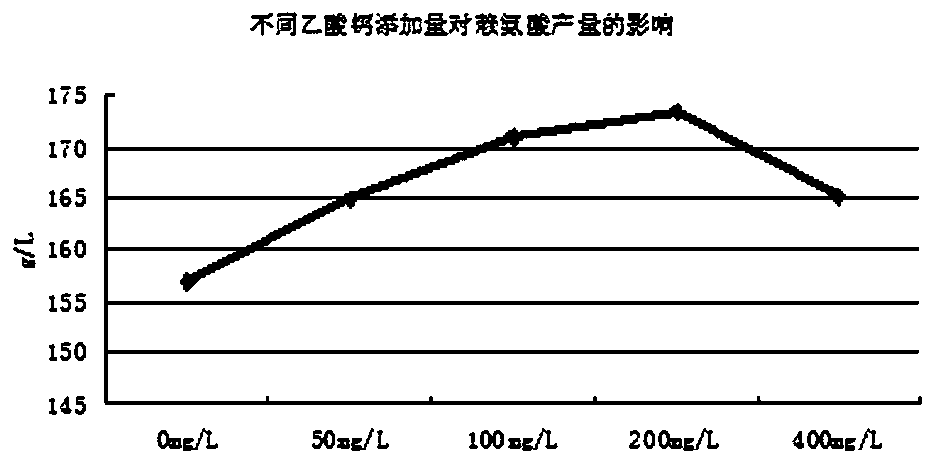

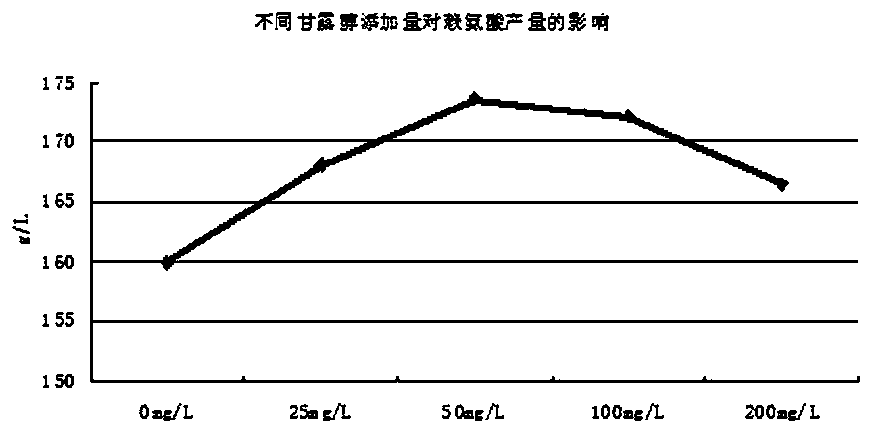

[0028] Corn husk treatment 300g / L, corn steep liquor 10g / L, potassium dihydrogen phosphate 2g / L, dipotassium hydrogen phosphate 2g / L, ferrous sulfate heptahydrate 0.2g / L, magnesium sulfate heptahydrate 0.2g / L, acetic acid Calcium 200mg / L, Mannitol 50mg / L, Biotin 10mg / L, Vitamin B 1 2mg / L, the solvent is water;

[0029] The preparation process is as follows: adding various raw materials into water, adjusting the pH to 6.8, sterilizing at 121° C. for 20 minutes, and cooling to 32° C. to obtain the product.

[0030] The fermentation process using the above-mentioned fermentation medium includes the following steps: placing the fermentation medium in a fermenter, then inserting the strain seed liquid according to the inoculation amount of 12%, controlling the temperature at 32°C, the tank pressure at 0.05MPa, and the air volume at 600L / h, the rotation speed is 350rpm, the pH is controlled at 6.8, ...

Embodiment 2

[0036] A lysine fermentation medium, which comprises the following components:

[0037] Corn husk treatment 200g / L, corn steep liquor 20g / L, potassium dihydrogen phosphate 1g / L, dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L, magnesium sulfate heptahydrate 0.1g / L, acetic acid Calcium 100mg / L, Mannitol 100mg / L, Biotin 5mg / L, Vitamin B 1 1mg / L, the solvent is water;

[0038] The preparation process is as follows: adding various raw materials into water, adjusting the pH to 6.8, sterilizing at 121° C. for 20 minutes, and cooling to 32° C. to obtain the product.

[0039] The fermentation process using the above-mentioned fermentation medium includes the following steps: placing the fermentation medium in a fermenter, then inserting the strain seed liquid according to the inoculum amount of 10%, controlling the temperature at 32°C, the tank pressure at 0.05MPa, and the air volume at 600L / h, the rotation speed is 350rpm, the pH is controlled at 6.8, the...

Embodiment 3

[0054] Using Corynebacterium glutamicum ATCC14997 as the fermentation strain, the amount of lysine produced by fermentation in Example 1 and Comparative Examples 1-3 was studied. The fermentation process was referred to in Example 1. The specific acid production by fermentation is shown in Table 1:

[0055] Table 1

[0056] group

[0057] As shown in Table 1, the amount of acid production in Example 1 is the highest, which is 17.4% higher than that of Comparative Example 1, 6.5% higher than that of Comparative Example 2, and 14.3% higher than that of Comparative Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com