Rotary distributor with point-to-point feeding discharging and point-to-point dust absorption

A rotary distributor, point-to-point technology, applied in the field of rotary distributors, can solve the problems of inaccurate material receiving elbow silo, small distance between discharge pipes, easy material channeling, etc., so as to achieve short sensing distance and avoid material channeling. , the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will now be described with reference to the accompanying drawings.

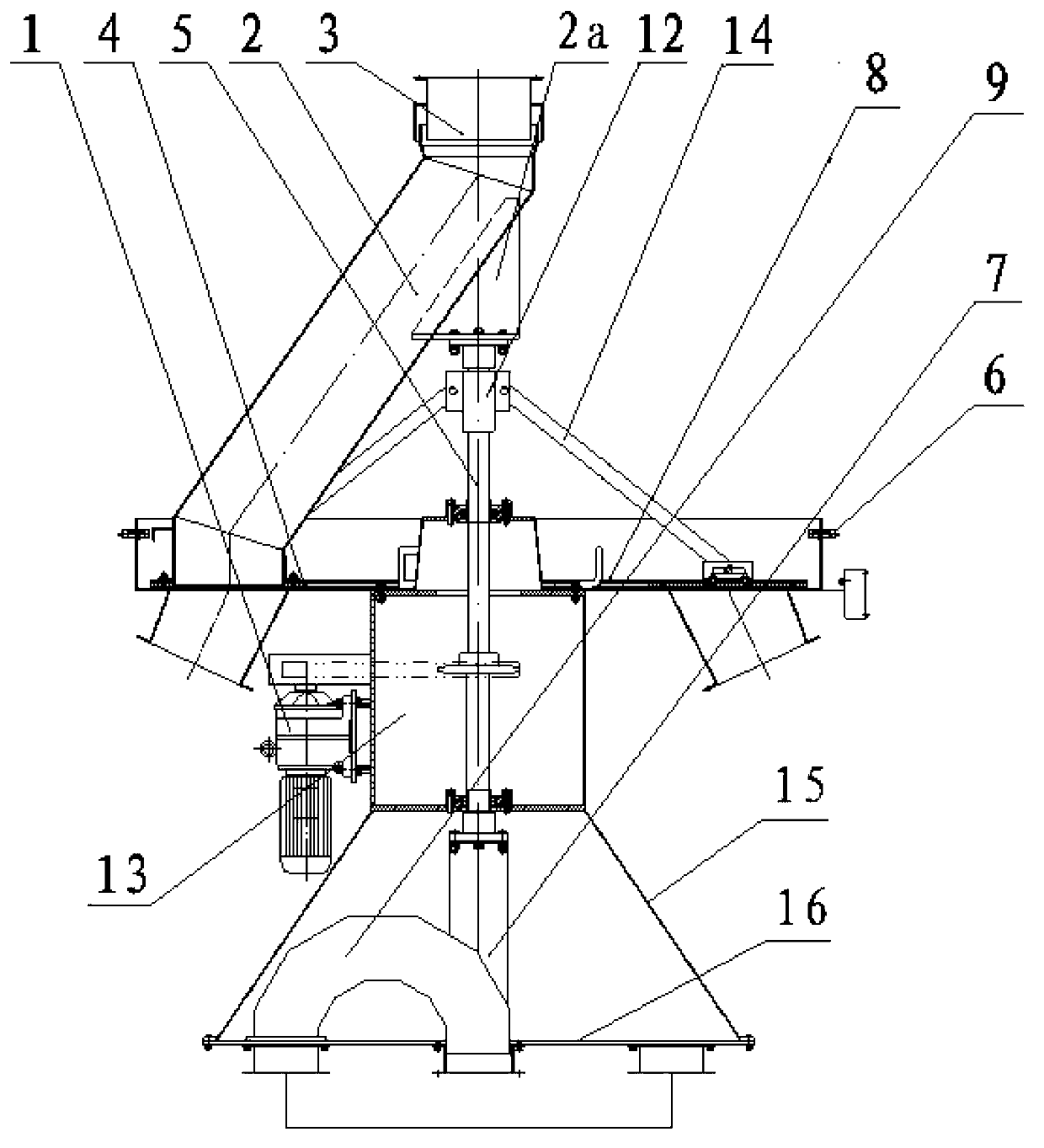

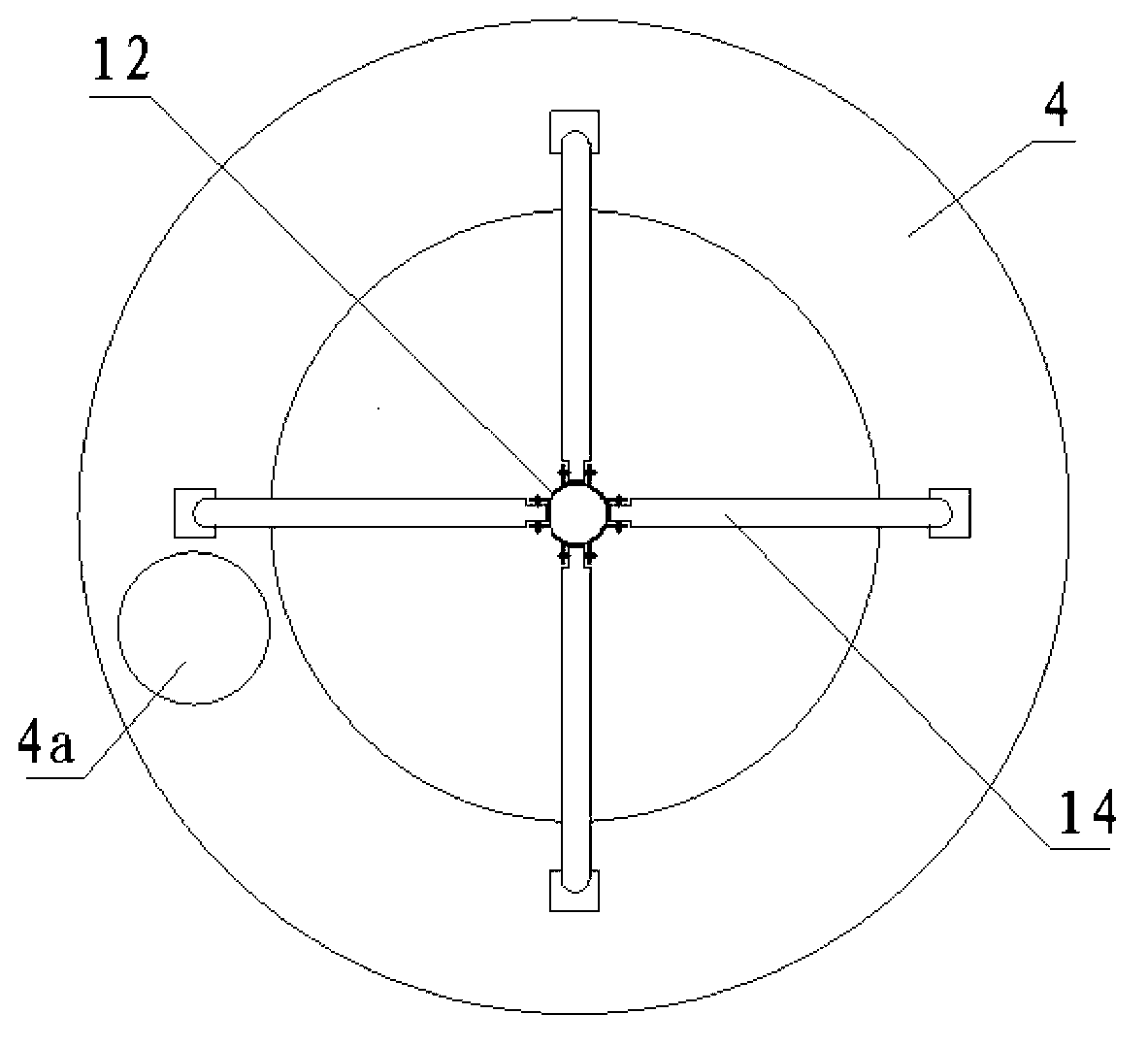

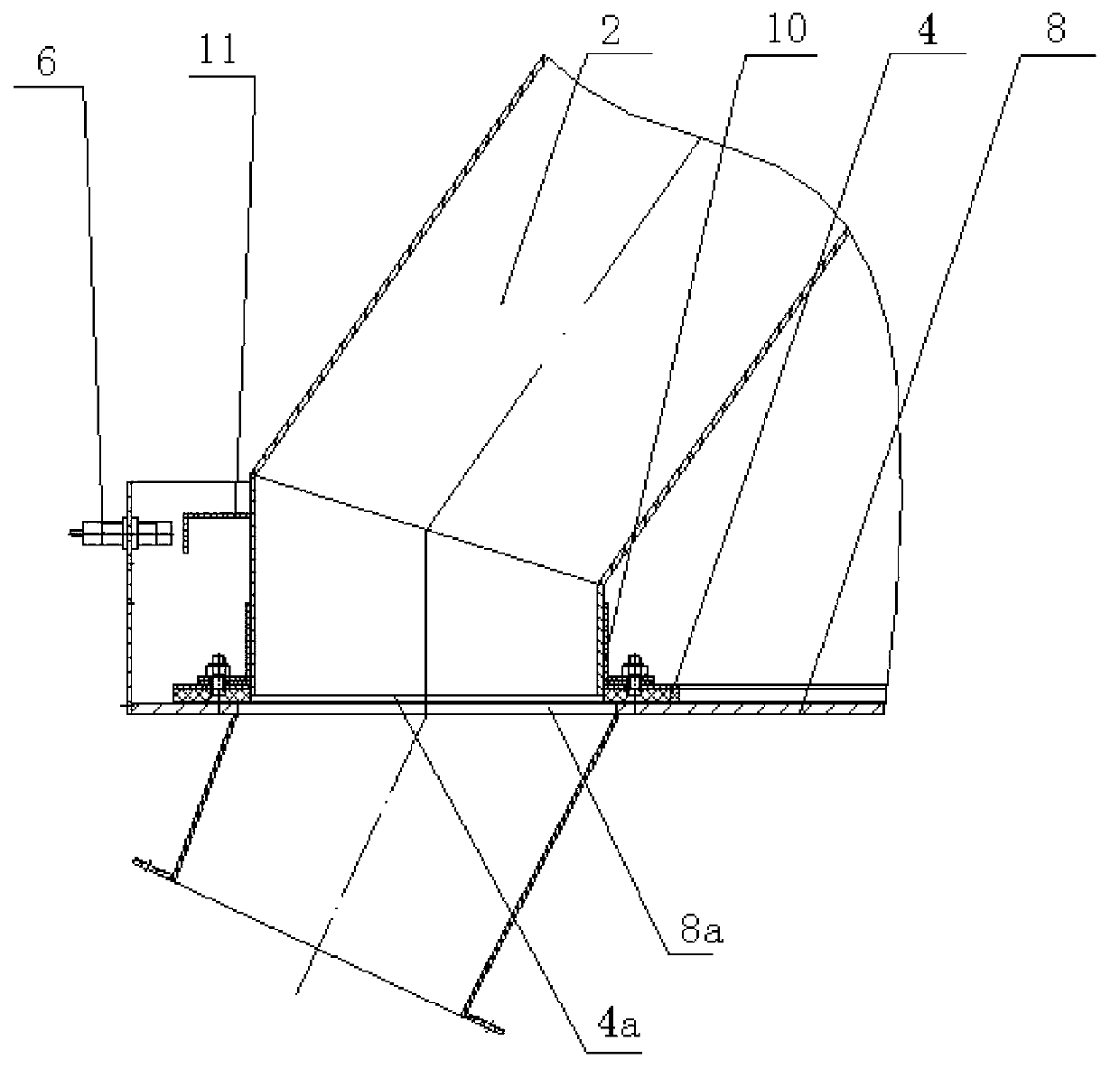

[0024] figure 1 , figure 2 , image 3 An embodiment of the rotary distributor for point-to-point feeding and point-to-point vacuuming of the present invention is given: the present invention includes a feed distribution platform assembly, a feed chute assembly and its drive part, and the drive part on the upper side of the feed distribution platform A shaft sleeve assembly 12 is installed on the main shaft 5 of the shaft sleeve assembly 12, and 3 to 4 umbrella-shaped support rods 14 protrude from the top of the shaft sleeve assembly 12 obliquely downward at the same central angle. On the feed distribution platform 8, it cooperates with the feed distribution platform 8. The radial width of the annular rotating disk 4 covers the multi-point feeding distribution port 8a on the feeding distribution platform 8. There is a blanking The opening 4a corresponds to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com