Space zinc-silver battery cathode plate module forming device and method thereof

A zinc-silver battery and forming device technology, which is applied to the electrodes of alkaline storage batteries, etc., can solve the problems of unsuitable zinc-silver paste, and achieve the effects of controlling paste overflow, uniform distribution, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

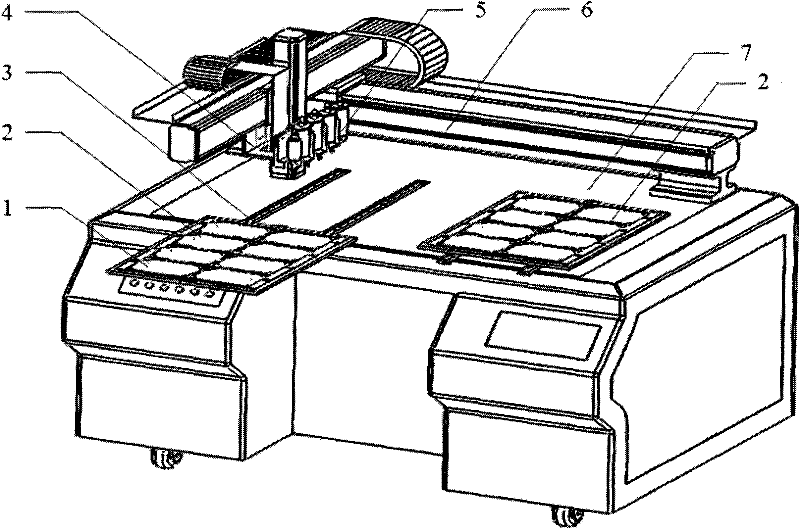

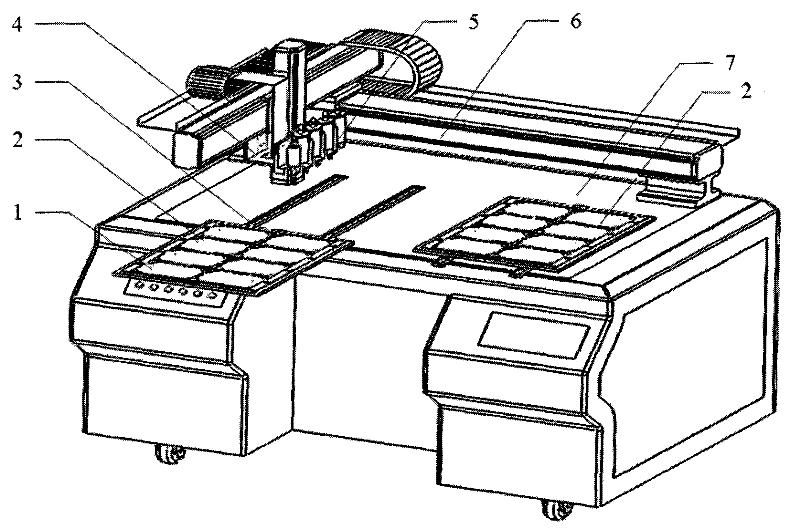

[0030] Such as figure 1 As shown, this embodiment includes: end plate 1, positioning tray 2, guide rail 3, pressing block 4, paste control valve 5, three-degree-of-freedom rectangular coordinate robot 6, workbench 7, controller 8, movable arm 9, motor 10 and an air pump 11, wherein: the end plate 1 is movably set on the workbench 7 through the guide rail 3, and the four paste control valves 5 are fixedly set on the movable arm of the three-degree-of-freedom rectangular coordinate robot 6.

[0031] The end plate 1 is provided with several positioning trays 2 for accommodating space zinc-silver battery cathode slice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com