Steel reinforced concrete sacrificial anode cathodic protection devices in atmospheric environment and method thereof

A reinforced concrete and sacrificial anode technology, which is applied in the field of sacrificial anode cathodic protection devices for reinforced concrete structures, to achieve the effects of saving manpower and material resources, significant economic and social benefits, and stable open circuit potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

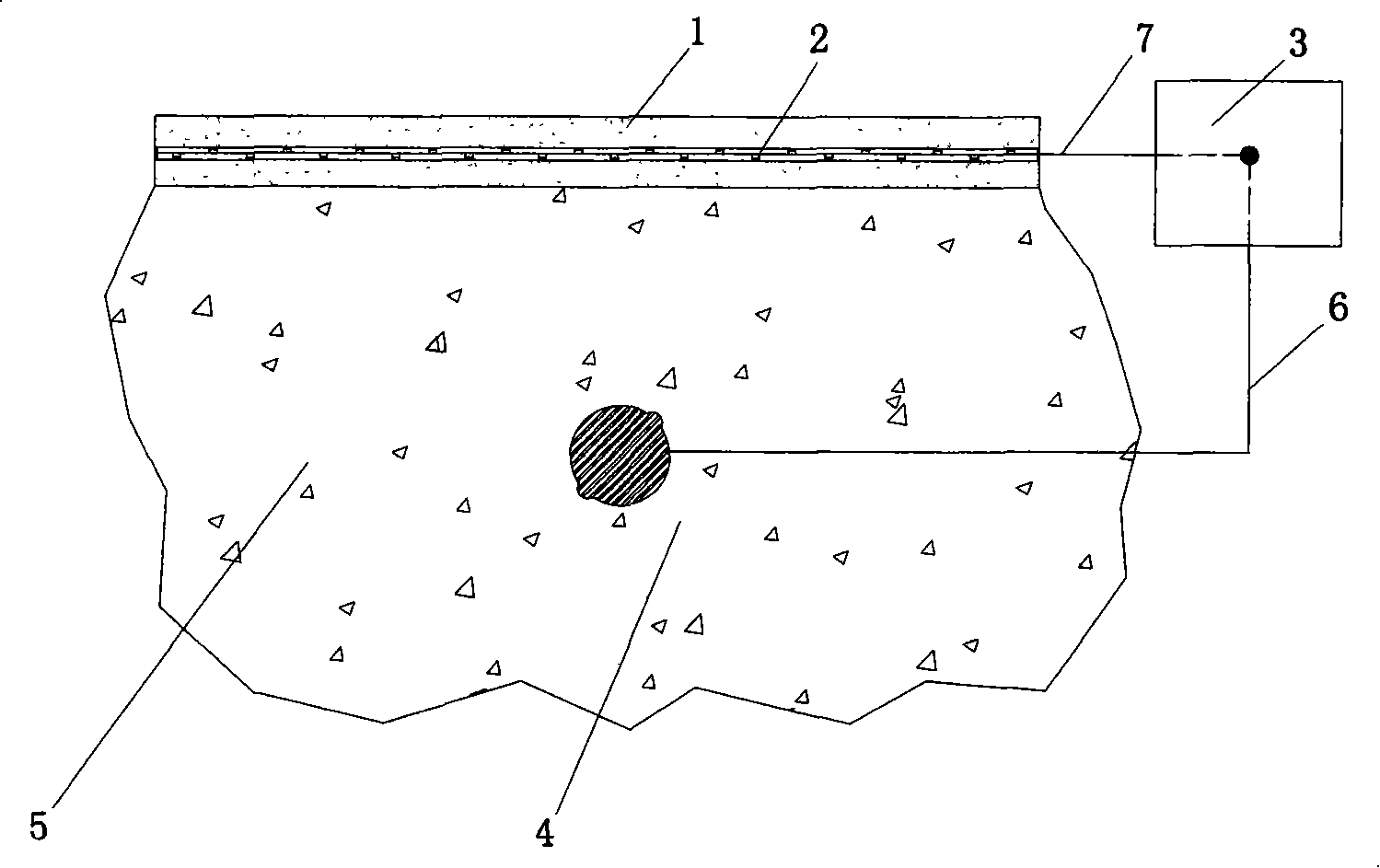

[0046] Embodiment 1, the cathodic protection method of reinforced concrete structure sacrificial anode in salt polluted atmospheric environment, refer to figure 1 : The main structure of the present invention includes active mortar 1, grid sacrificial anode 2, junction box 3, steel bar 4, reinforced concrete structure 5, cathode cable 6 and anode cable 7.

[0047] First, a small piece of concrete is chiseled on the reinforced concrete structure to expose a small section of steel bar 4, and the cathode cable 6 is welded on the steel bar 4; Both cathode cable and anode cable welds need to be waterproof and sealed. After removing the dirt and small metal parts on the surface of the reinforced concrete structure 5, lay a layer of active mortar 1, lay the grid-shaped sacrificial anode 2 that has welded the anode cable on the surface of the active mortar 1, and then lay a layer of active mortar 1. The cathode cable 6 and the anode cable 7 are connected together through the junctio...

Embodiment 2

[0048] Embodiment 2 is basically the same as Embodiment 1, but with the following changes: the sacrificial anode is made of pure zinc. The water-cement ratio of the active mortar is 0.4:1. The lime-sand ratio of the active mortar is 0.5:1. The active additive is lithium bromide and lithium nitrate in a ratio of 1:1, which is a weight ratio. The dosage of active additive is 0.15g / cm 3 . The dosage range of the synthetic fiber is 0.15% of the weight of the mortar, and the synthetic fiber is polypropylene fiber. Sacrificial anodes are fixed to the reinforced concrete façade.

Embodiment 3

[0049] Embodiment 3 is basically the same as Embodiment 1, but has the following changes:

[0050] The water-cement ratio of the active mortar is 0.55:1. The gray-sand ratio of the active mortar is 0.6:1, the active additive is lithium bromide and lithium nitrate with a mass ratio of 1:1, and the dosage range of the active additive is 0.50g / cm 3 . The content of synthetic fiber is 0.5% of the mortar weight. The synthetic fiber incorporated is cellulose. The sacrificial anode is fixed on the bottom surface of reinforced concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com