High-performance shrinkage-free cement-based grouting material prepared by manufactured sand and preparation method of cement-based grouting material

A machine-made sand and cement-based technology, which is applied in the field of cement-based materials, can solve the problems of surface laitance and easy sinking of large-volume fine aggregates, and achieve high uniformity, good fluidity, and mitigation of abuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

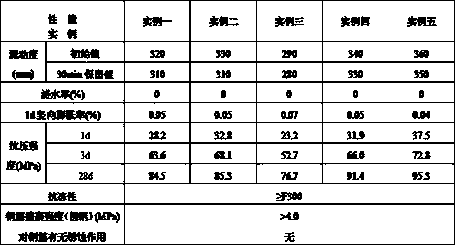

Examples

Embodiment 1

[0033] Example 1: A high-performance non-shrinkage cement-based grout prepared with machine-made sand

[0034] This high-performance non-shrinkage cement-based grouting material is composed of machine-made sand, ordinary Portland cement, fly ash, slag powder, fiber, heavy material (polycarboxylate superplasticizer dry powder, defoamer, plastic retainer, anti-early shrinkage agent and water-retaining agent), light materials (rapid hardening sulfoaluminate cement, expansion agent and gypsum are mixed), and the ratio of various materials is:

[0035] Machine-made sand 0-0.6mm 24%

[0036] Machine-made sand 0.6-2.36mm 25%

[0037] Machine-made sand 2.36-4.75mm 5%

[0038] P.O42.5 cement 35%

[0039] Fly Ash 6%

[0040] Slag powder 1.854%

[0041] Polypropylene fiber 0.02%

[0042] Polycarboxylate superplasticizer 0.09%

[0043] Sodium Glucose Plasticizer 0.0075%

[0044] Defoamer 0.006%

[0045] Anti-premature shrinkage agent 0.0175%

Embodiment 2

[0052] Example 2: A high-performance non-shrinkage cement-based grout prepared with machine-made sand

[0053] The similarities with Example 1 are no longer described, and the differences are as follows:

[0054] Machine-made sand 0-0.6mm 20%

[0055] Machine-made sand 0.6-2.36mm 25%

[0056] Machine-made sand 2.36-4.75mm 5%

[0057] P.O42.5 cement 36%

[0058] Fly Ash 6%

[0060] Polypropylene fiber 0.02%

[0061] Polycarboxylate superplasticizer 0.09%

[0062] Sodium Glucose Plasticizer 0.0075%

[0063] Defoamer 0.006%

[0064] Anti-premature shrinkage agent 0.0175%

[0065] Cellulose ether water retaining agent 0.005%

[0066]R.SAC42.5 cement 1.5%

[0067] AC expansion agent 1%

[0068] Gypsum 1.004%

[0069] The cement-based grouting material obtained in this example can be used directly after adding water and stirring evenly, wherein the weight ratio of water to material is 0.135.

Embodiment 3

[0070] Example 3: A high-performance non-shrinkage cement-based grout prepared with machine-made sand

[0071] The similarities with Example 1 are no longer described, and the differences are as follows:

[0072] Machine-made sand 0-0.6mm 26%

[0073] Machine-made sand 0.6-2.36mm 26%

[0074] Machine-made sand 2.36-4.75mm 8%

[0075] P.O42.5 cement 32%

[0076] Fly Ash 3%

[0078] Polypropylene fiber 0.03%

[0079] Polycarboxylate superplasticizer 0.08%

[0080] Sodium Glucose Plasticizer 0.0075%

[0081] Defoamer 0.006%

[0082] Anti-premature shrinkage agent 0.0175%

[0083] Cellulose ether water retaining agent 0.003%

[0084] R.SAC42.5 cement 1.5%

[0085] AC expansion agent 1%

[0086] Gypsum 1.006%

[0087] The cement-based grouting material obtained in this example can be used directly after adding water and stirring evenly, wherein the weight ratio of water to material is 0.125.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com