Composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof

A technology of high-chromium cast iron and composite rolls, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of increased production costs and high prices of rolls, and achieve low production costs, less inclusions, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

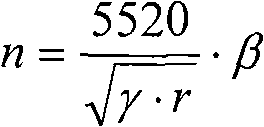

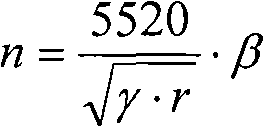

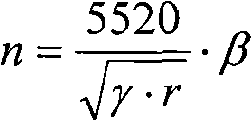

Image

Examples

Embodiment 1

[0044] The outer diameter of the high chromium cast iron composite roll of this embodiment is φ 370mm, the thickness of the roll outer layer is 60mm, and the unilateral processing amount of the roll outer layer is 8mm, and the outer layer (i.e. the roll body) and the roll core of the high chromium cast iron composite roll are respectively 1000kg and 1500kg Intermediate frequency induction furnace melting, its manufacturing process steps are:

[0045] The first step: smelting of the outer layer of high chromium cast iron:

[0046] ①Mix the alloy iron filings of the high-nickel-chromium infinite chilled cast iron roll, the silicon-calcium-barium alloy, and the low-carbon steel scrap, and compact it on a press to a size of (150-250) mm×(150-250) mm×(150~250)mm is a block whose length, width and height are 150-250mm respectively, and then put the compacted block into an induction furnace to heat and melt, and then add carbon ferrochrome and medium carbon ferromanganese in turn,

...

Embodiment 2

[0064] The body size of the high chromium cast iron composite roll in this embodiment is 650×1400mm, the outer layer (that is, the roll body) and the roll core of the composite roll are smelted in a 3t intermediate frequency induction furnace and a 5t / h cupola respectively. The manufacturing process steps are:

[0065] The first step: smelting of the outer layer of high chromium cast iron:

[0066] ①Mix the alloy iron filings of the high-nickel-chromium infinite chilled cast iron roll, the silicon-calcium-barium alloy, and the low-carbon steel scrap, and compact it on a press to a size of (150-250) mm×(150-250) mm×(150~250)mm squares, then put the compacted squares into the induction furnace to heat and melt, then add carbon ferrochrome and medium carbon ferromanganese in turn,

[0067] ②After the molten iron is melted, when the temperature of the molten iron reaches 1501°C, add aluminum, then add ferro-titanium and ferro-boron in sequence, and when the temperature of the mo...

Embodiment 3

[0084] The outer diameter of the high chromium cast iron composite roll of this embodiment is φ 370mm, the thickness of the roll outer layer is 60mm, and the unilateral processing amount of the roll outer layer is 8mm, and the outer layer (i.e. the roll body) and the roll core of the high chromium cast iron composite roll are respectively 1000kg and 1500kg Intermediate frequency induction furnace melting, its manufacturing process steps are:

[0085] The first step: smelting of the outer layer of high chromium cast iron:

[0086] ①Mix the alloy iron filings of the high-nickel-chromium infinite chilled cast iron roll, the silicon-calcium-barium alloy, and the low-carbon steel scrap, and compact it on a press to a size of (150-250) mm×(150-250) mm×(150~250)mm squares, then put the compacted squares into the induction furnace to heat and melt, then add carbon ferrochrome and medium carbon ferromanganese in turn,

[0087] ② After the molten iron is melted, when the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com