High-alloy metals reinforced by diamond-like framework and method for making the same

a diamond-like framework and high-alloy metal technology, applied in the field of metal alloys, can solve the problems of low fracture toughness of conventional ceramic materials, inability to adequately control the fine structure of solidifying metals, and rapid cooling technology, and achieves high uniformity, superior structural stability, and increased thermal stability and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

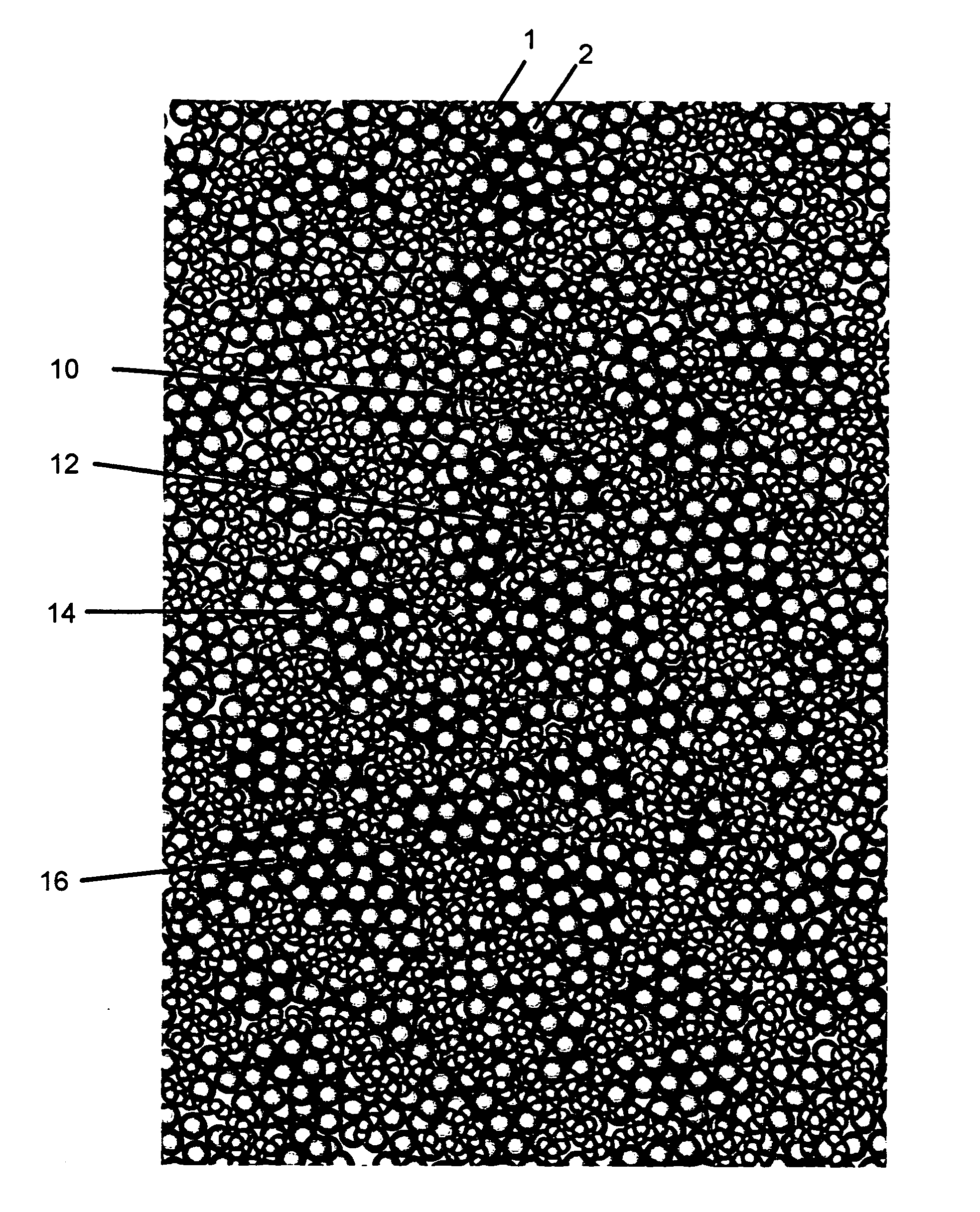

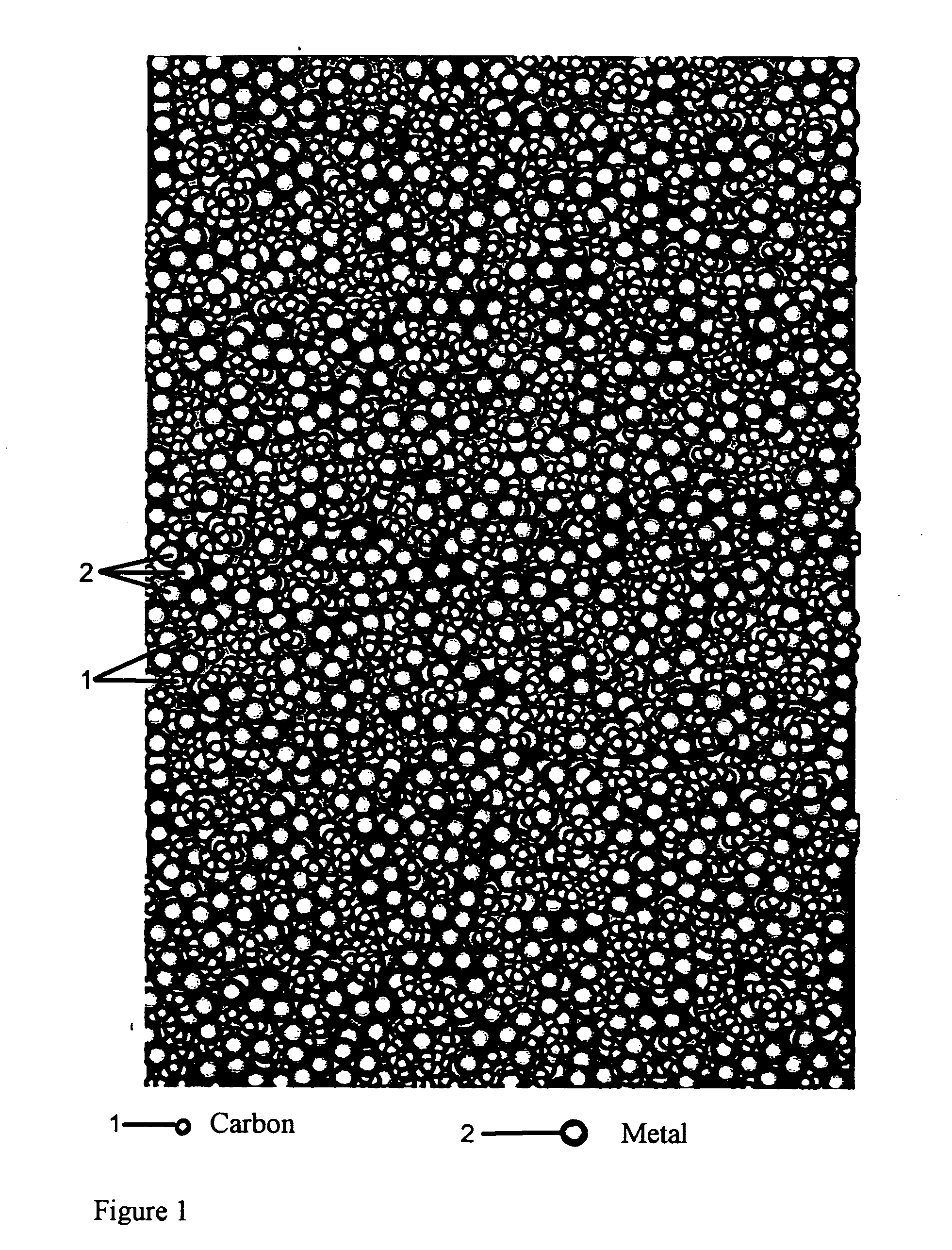

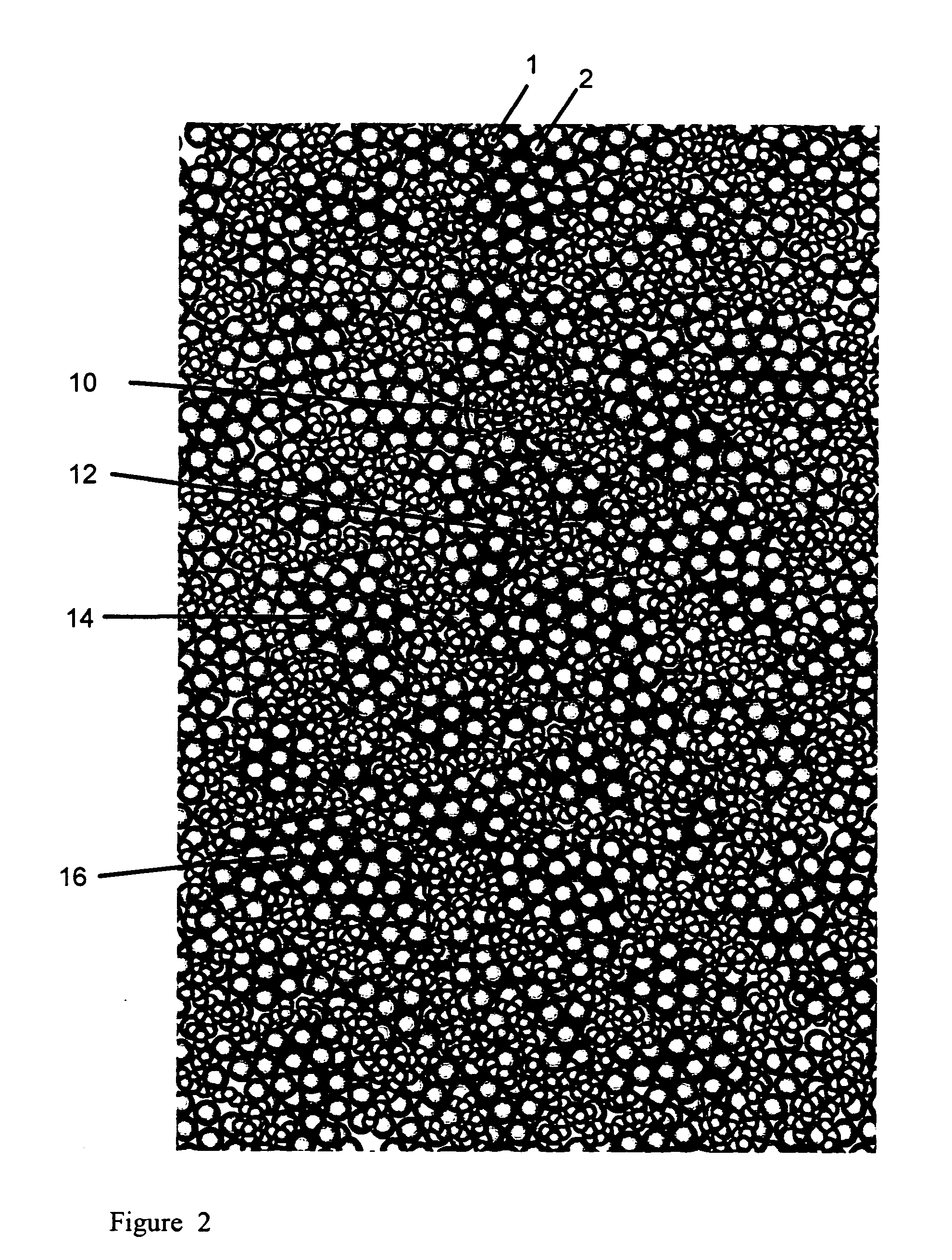

Image

Examples

example 1

[0063] Five micron films that include 52 to 80 atomic % Cr, 36 to 15 atomic % carbon, 7 to 3 atomic % silicon, and 5 to 2 atomic % oxygen, were deposited in accordance with at least one embodiment of the present invention, at a substrate temperature of about 150 degrees Celsius. Polymethylphenyldisiloxane, (CH3)3SiO[CH3C6H5SiO]3Si(CH3)—, was used as for the precursor, introduced at a flow rate of 1.1 to 1.5 cm3 / hr, to achieve a growth rate of 5 microns / hr.

[0064] Table 1 shows the electrical resistivity and structure as a function of chromium content. All films in Table 1 demonstrate thermal stability exceeding 1100° C. in the absence of oxygen, and sustain a 30-minute exposure in air up to a temperature of 950° C. After the aforementioned high temperature exposure, minor changes in the mechanical properties occur, accompanied by an increase in the percentage of nano-crystallinity. The films posses a micro-hardness of 12 to 15 GPa, high wear resistance, high thermal shock resistance...

example 2

[0065] Five micron films that include 50 to 80 atomic % Fe0.72Cr0.18Ni0.10 metal alloy, 37.5 to 15 atomic % carbon, 9.5 to 3.8 atomic % silicon, and 3 to 1.2 atomic % oxygen, were deposited in accordance with the preferred embodiments of the present invention. As in Example 1, substrate temperature was 150° C., and the polymethylphenyldisiloxane precursor was introduced at a flow rate of 1.1 to 1.5 cm3 / hr to achieve a growth rate was 5 microns / hr.

[0066] Table 2 shows the electrical resistivity and structure as a function of metal alloy content. All films in Table 2 demonstrate thermal stability up to at least 900° C. in the absence of oxygen, and sustain a 30 minute exposure in air up to a temperature of 900° C. These films possess a micro hardness in the range of 11 to 13 GPa, high wear resistance, very high thermal shock resistance, low friction, and uniform structure.

[0067] The alloy films in Table 2 have a wide range of applications, particularly as protective coatings, where ...

example 3

[0068] A series of 1 micron thick films of amorphous and nano-crystalline hafnium reinforced by a carbon diamond-like framework and stabilized by silicon and oxygen were deposited on silicon wafers in accordance with at least one embodiment of the present invention and under similar deposition conditions described in example 1. The chemical composition of the films was 40 atomic % hafnium, 45 atomic % carbon, 9 atomic % silicon, and 6 atomic % oxygen. These films have electrical conductivity in the range of 3×10−3 to 5×10−4 Ohm-cm., and demonstrated high thermal shock resistance and high chemical corrosion resistance in aggressive environments at temperatures exceeding 500° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com