Nanometer ZrO2 compound function fabric and manufacturing method and applications

A composite function and nano-technology, applied in dry-cleaning fiber products, textiles and papermaking, single-component polyester rayon, etc., can solve problems such as uneven dispersion, achieve a wide chromatographic range, rich sources of raw materials, and good UV resistance and the effect of absorbing near-infrared rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

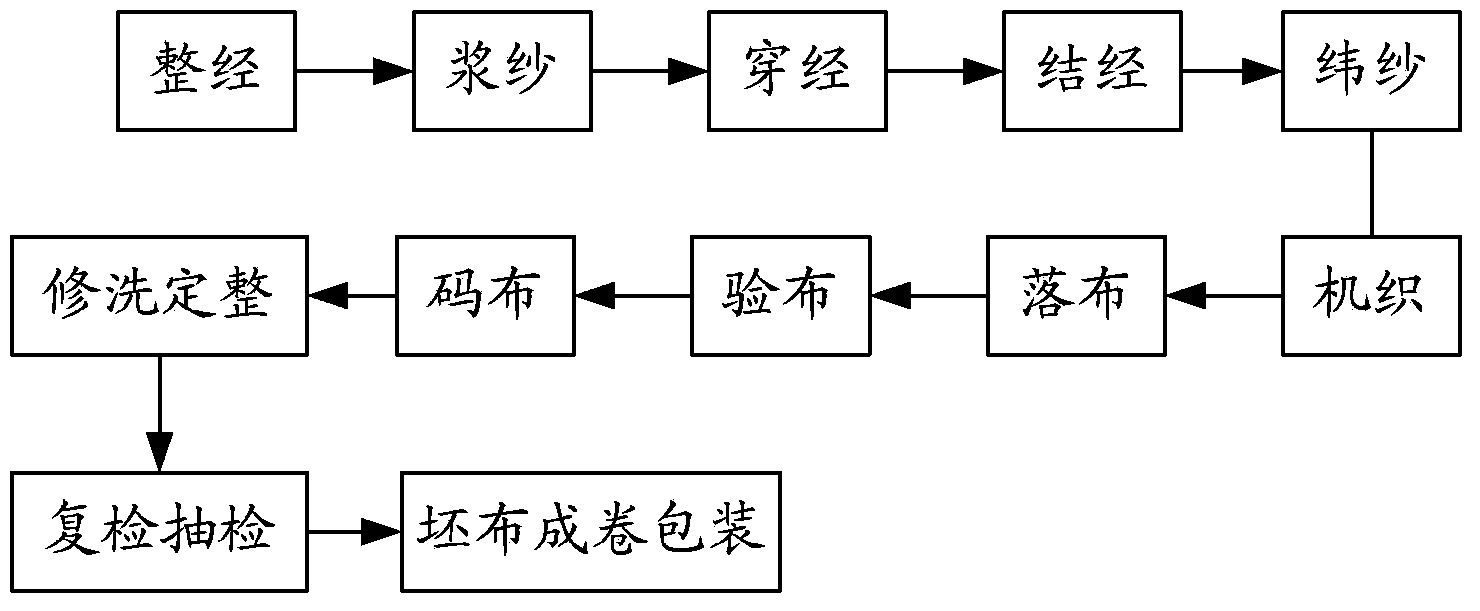

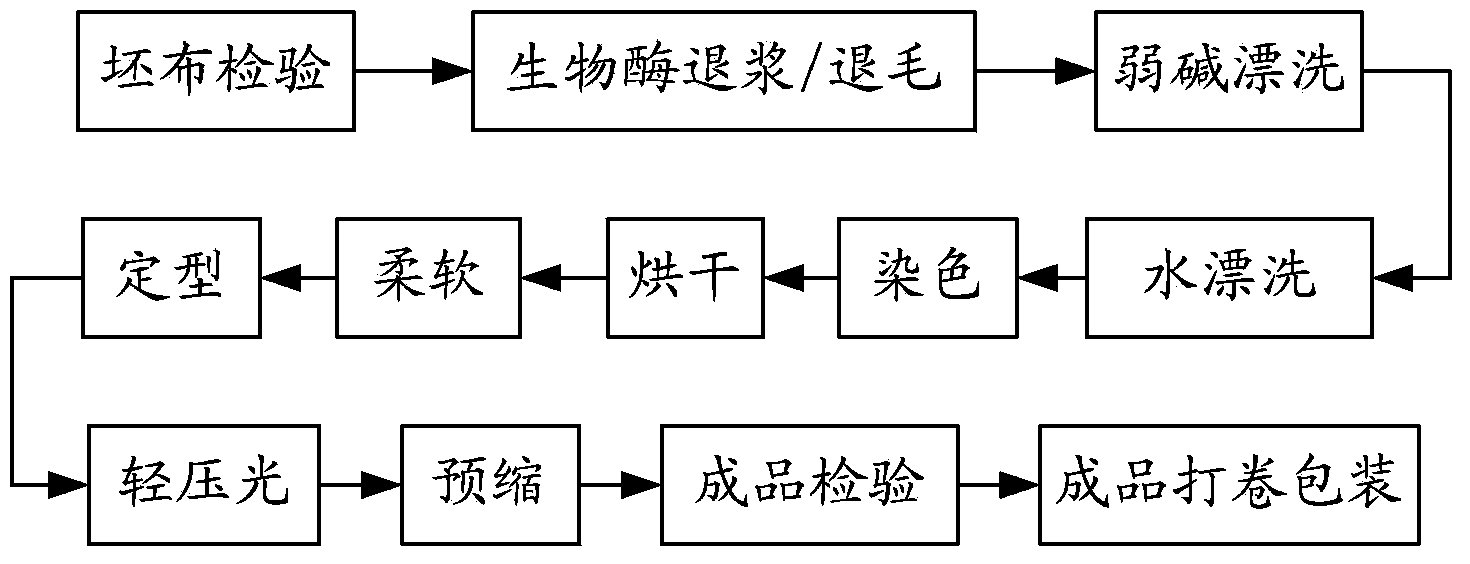

Embodiment 1

[0040] In this embodiment, nano ZrO 2 Composite functional tencel fabric, made of nano ZrO 2 Functional fiber and cotton interwoven, nano ZrO 2 The composite polyester fiber is used as the weft weave of the fabric, the cotton fiber is used as the warp weave of the fabric, and the nano ZrO in the fabric is 2Functional fiber content is 40wt%, fiber content is 60wt%; nano ZrO 2 Functional fibers contain the following raw material components: Nano ZrO 2 (particle size 10-50nm) powder: 1.8 parts by weight; polybutylene terephthalate: 2.2 parts by weight; polyethylene terephthalate: 96 parts by weight; auxiliary agent: trace amount, the auxiliary agent contains oil The reaction product of potassium ethyl ester sulfonate and rosin amine, ethylene-acrylic acid copolymer wax. The additive content is nano ZrO 2 5% of powder weight. Nano-ZrO 2 The monofilament fineness of the composite polyester fiber is 0.5D, the fiber breaking strength is greater than 3.0cN / dtex, the fiber speci...

Embodiment 2

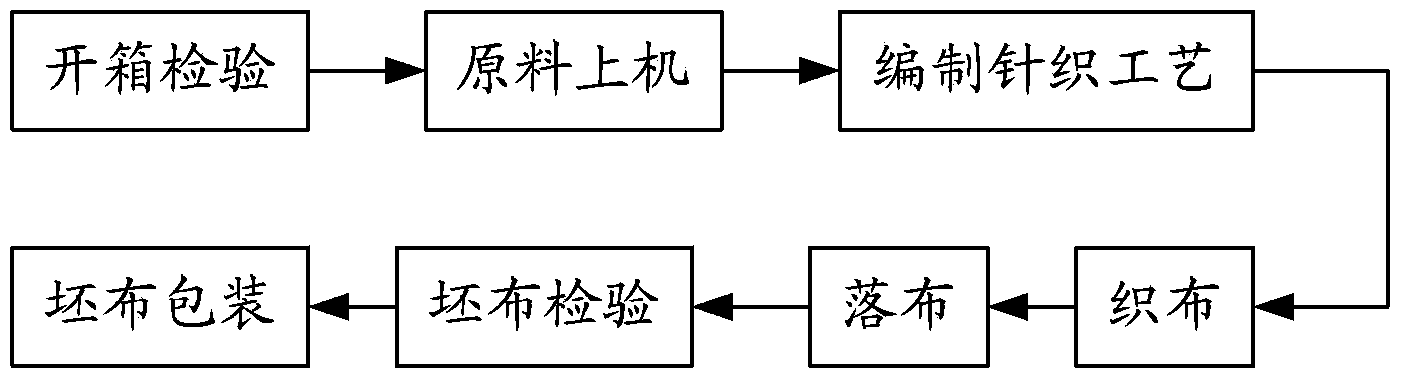

[0045] In this embodiment, nano ZrO 2 Composite functional venous socks, made of nano ZrO 2 Knitted from polyester functional fiber and spandex fiber, nano ZrO 2 Composite polyester fiber and spandex fiber mixed knitting, nano ZrO in the fabric 2 Functional fiber content is 90wt%, spandex fiber content is 10wt%; nano ZrO 2 Functional fibers contain the following raw material components: Nano ZrO 2 (particle size 10-60nm) powder: 3 parts by weight; polybutylene terephthalate: 4 parts by weight; polyethylene terephthalate: 93 parts by weight; auxiliary agent: trace amount, the auxiliary agent contains oil The reaction product of potassium ethyl ester sulfonate and rosin amine, ethylene-acrylic acid copolymer wax. The additive content is nano ZrO 2 6% of powder weight. Nano-ZrO 2 The monofilament fineness of the composite polyester fiber is 1.0D, the fiber breaking strength is greater than 3.2cN / dtex, and the fiber specification is 30D / 16F double strand; the specification ...

Embodiment 3

[0051] In this embodiment, nano ZrO 2 Composite functional fabric, made of nano ZrO 2 Functional fibers and hemp fibers are interwoven, nano ZrO 2 The composite polyester fiber is used as the weft weave of the fabric, the hemp fiber is used as the warp weave of the fabric, and the nano ZrO in the fabric is 2 The functional fiber content is 45wt%, and the hemp fiber content is 55wt%; nano ZrO 2 Functional fibers contain the following raw material components: Nano ZrO 2 Powder (10-60nm particle size): 3 parts by weight; polybutylene terephthalate: 5 parts by weight; polyethylene terephthalate: 92 parts by weight; auxiliary agent: trace amount, the auxiliary agent contains oil The reaction product of potassium ethyl ester sulfonate and rosin amine, ethylene-acrylic acid copolymer wax. The additive content is nano ZrO 2 8% of the weight. Nano-ZrO 2 The monofilament fineness of the composite polyester fiber is 2D, the fiber breaking strength is greater than 3.2cN / dtex, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com