Bone repair material allowing injection of multi-pore structure and preparation method of bone repair material

A pore structure and bone repair technology, applied in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of insufficiently combined pore structure without cell growth, etc., to promote the transmission of nutrients and promote cell adhesion and growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

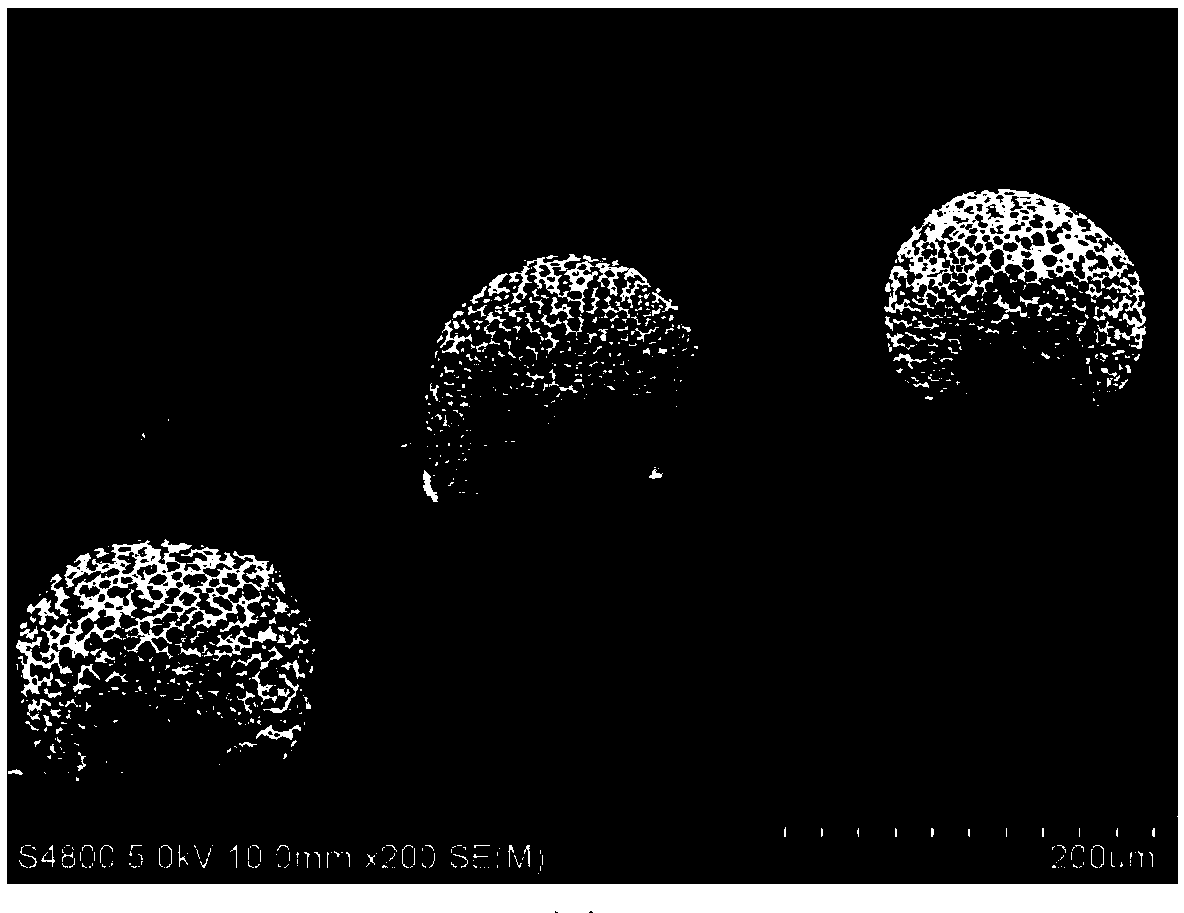

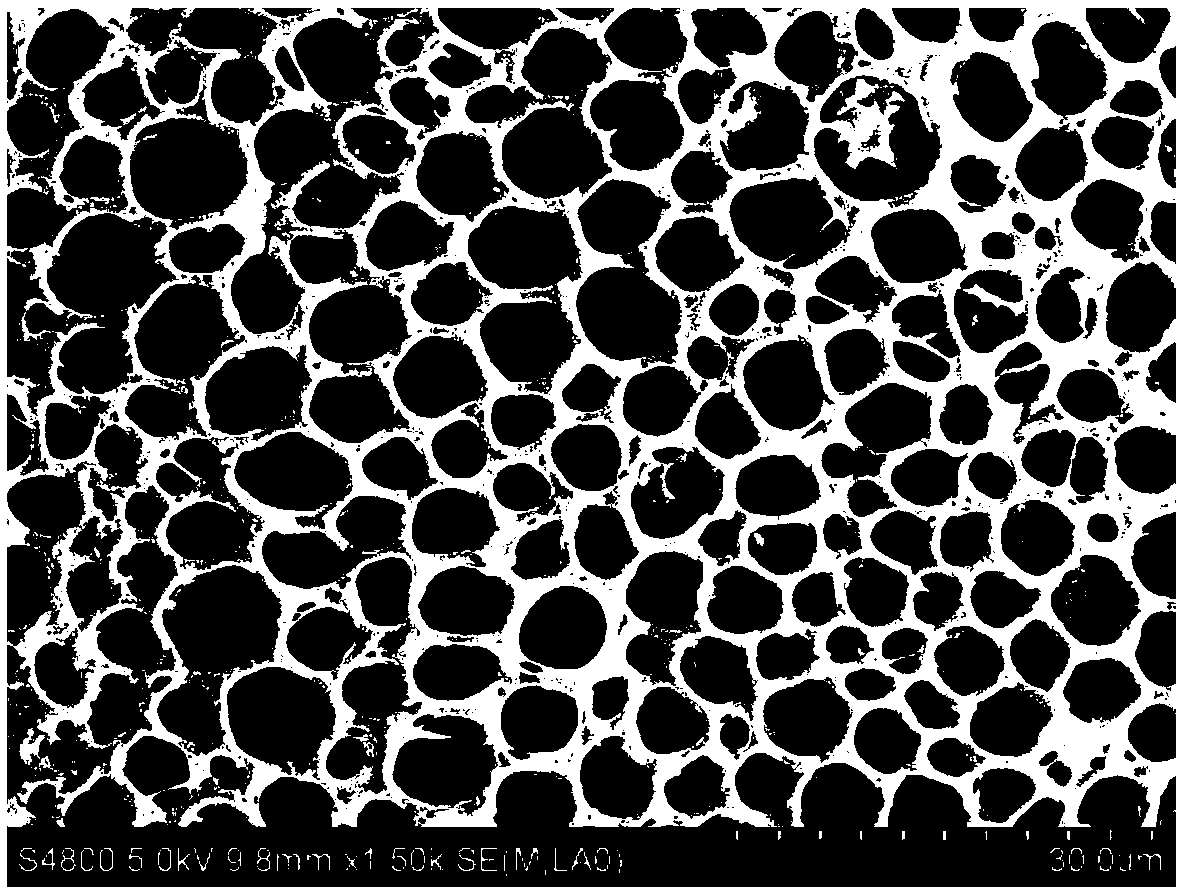

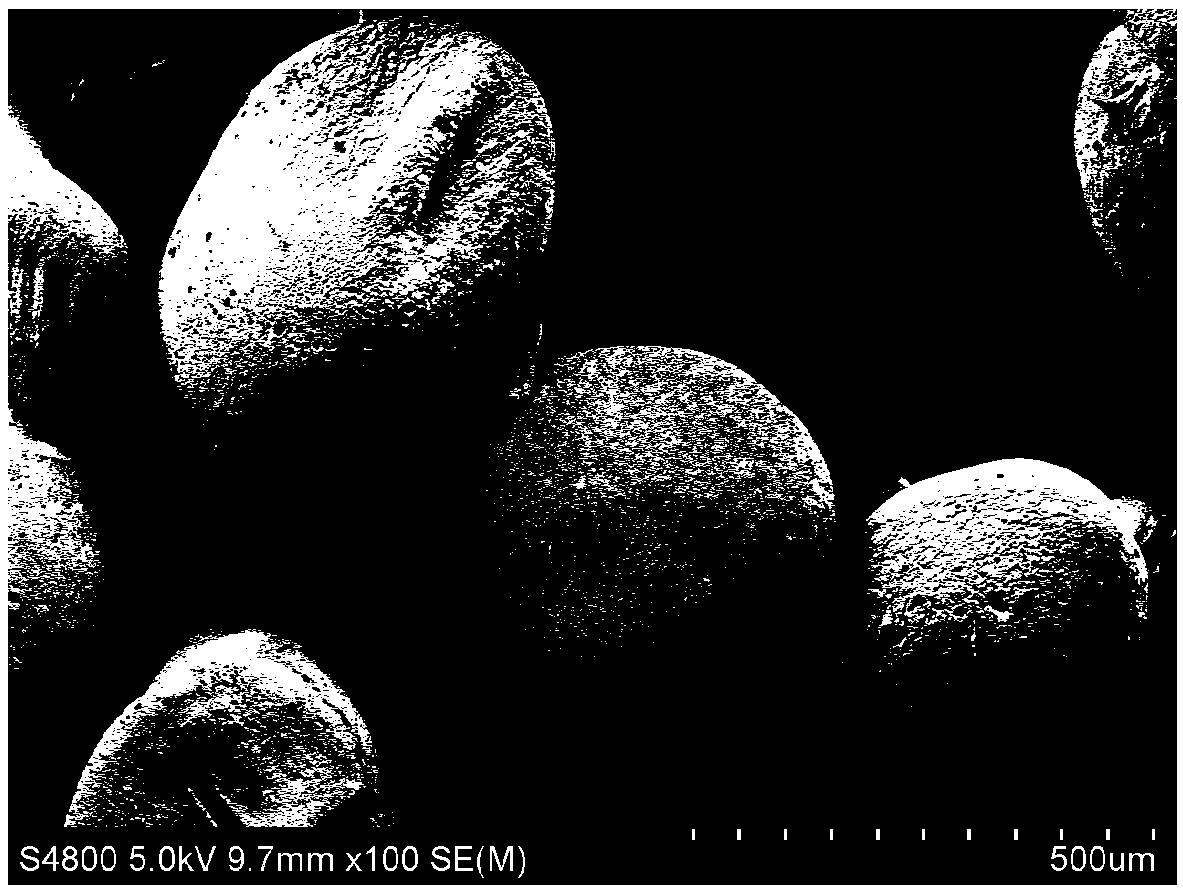

[0051] In this example, blank polylactic-co-glycolic acid (PLGA) porous microspheres and HA composite PLGA porous microspheres (HA-PLGA porous microspheres) with different hydroxyapatite (HA) contents were prepared.

[0052] 1. Preparation of PLGA porous microspheres

[0053] Weigh 1.8g of PLGA and add it to 36mL of dichloromethane, stir well at room temperature, the molecular weight of PLAG is 8.5w, and the mass ratio of LA and GA is LA / GA=85 / 15, then add 0.025g / mL of bicarbonate Ammonium solution 6mL, ultrasonic emulsification treatment for 5min, add 0.025g / mL ammonium bicarbonate solution 6mL, ultrasonic emulsification treatment for 15min, to obtain a uniformly dispersed W / O emulsion, transfer the W / O emulsion to 300mL10g / L polyvinyl alcohol (PVA) solution to obtain a W / O / W double emulsion, add 300mL deionized water, stir overnight to ensure that the dichloromethane is completely evaporated, wash with deionized water several times, and filter through a filter screen with a ...

Embodiment 2

[0069] In this example, the preparation of dopamine-hyaluronic acid (HA-DOPA), the steps are as follows:

[0070] (1) To the sodium hyaluronate (Mw=340kDa) aqueous solution with a concentration of 11.5mg / mL, add a solution of N-hydroxysuccinimide (NHS) with a concentration of 46mg / mL dropwise, and then add a solution with a concentration of 150mg / mL 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDCI) solution, stirred for 2 hours, added dropwise an aqueous solution of dopamine hydrochloride with a concentration of 2 mmol / L, stirred for 12 hours, two The pH value was controlled at 5.0 during the stirring reaction process, and the operation of this step was carried out under nitrogen protection. The molar ratio of EDCI, NHS, dopamine hydrochloride and the carboxyl group on sodium hyaluronate was 6:4:3:1;

[0071] (2) Dialyze the reaction solution obtained in step (1) with a dialysis membrane (MW=3.5-8kDa) in ultrapure water with a pH value of 3.5 for 48 hours, and ...

Embodiment 3

[0074] In this example, to prepare HA-DOPA, the steps are as follows:

[0075] (1) Add dropwise the NHS solution with the concentration of 50mg / mL to the sodium hyaluronate (Mw=500kDa) aqueous solution with the concentration of 15mg / mL, then add the EDCI solution with the concentration of 150mg / mL dropwise, stir the reaction for 3h, add dropwise Dopamine hydrochloride aqueous solution with a concentration of 0.5mmol / L was stirred for 14 hours, and the pH value was controlled at 4.8 during the two stirring reactions. The operations of this step were all carried out under nitrogen protection. EDCI, NHS, dopamine hydrochloride and sodium hyaluronate The molar ratio of the carboxyl groups on is 1:2:2.5:1;

[0076] (2) Dialyze the reaction solution obtained in step (1) with a dialysis membrane (MW=3.5-8kDa) in ultrapure water with a pH value of 3.0 for 48 hours, and then vacuum freeze-dry to obtain HA-DOPA, and store the sample in a desiccator middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com