Method for surface modification of dental implant

A surface modification, dental implant technology, applied in the direction of dental prosthesis, dentistry, dental preparations, etc., can solve the problem that the growth of surrounding bone tissue cannot effectively promote wound healing, the bonding strength of surrounding tissue is low, and the brittleness of hydroxyapatite Large and other problems, to achieve the effect of alleviating the mismatch of thermal expansion coefficients, enhancing the bonding strength, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The threaded titanium dental implants on the mechanical surface were cleaned with absolute ethanol, acetone, deionized water and ultrasonic wave for 10 minutes; then cleaned with HF:HNO 3 :H 2 O=1:3:6 acid solution for acid etching; finally use deionized water and ultrasonic cleaning for 10 minutes. Take out with tweezers and blow dry, set aside.

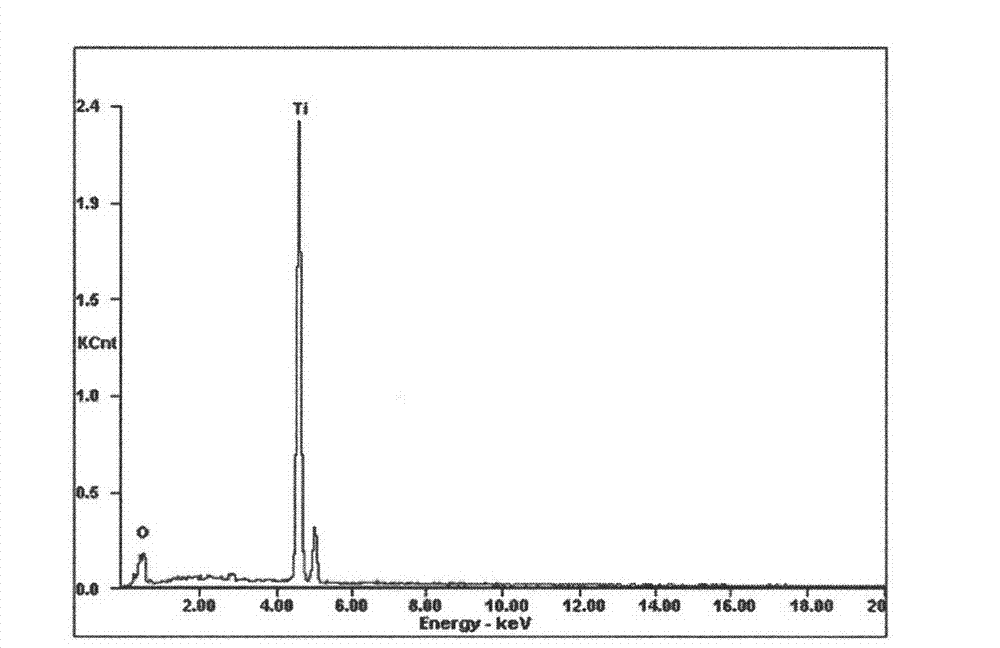

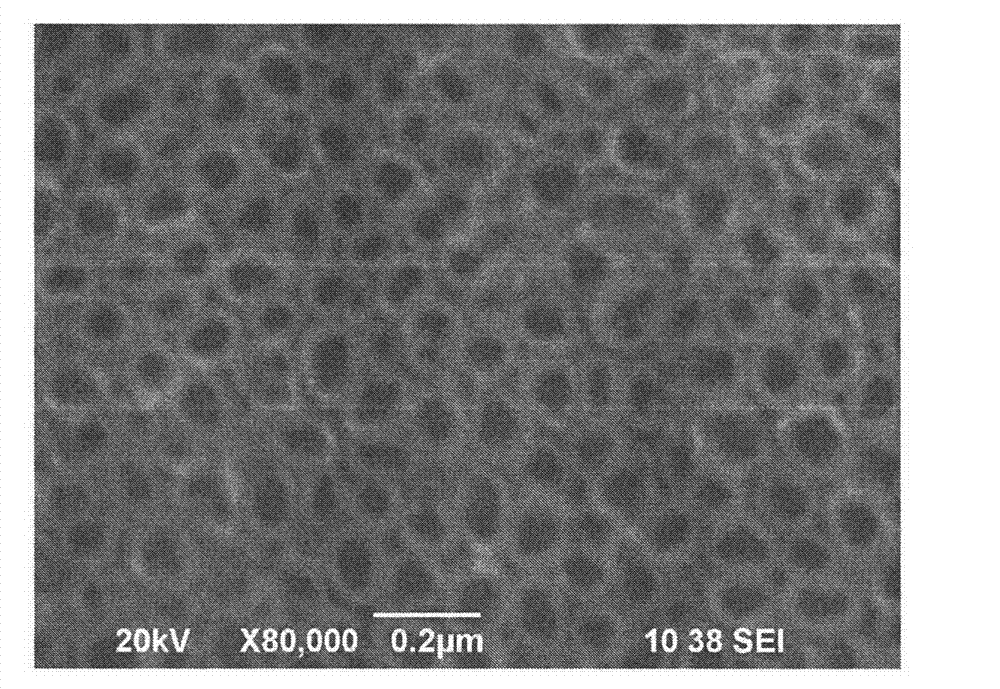

[0023] (2) Prepare 5w% hydrofluoric acid solution at room temperature as the electrolyte for anodic oxidation, use titanium implants as working electrodes, and 4 platinum electrodes as counter electrodes evenly distributed around the titanium dental implants with a working distance of 4 cm. Under magnetic stirring (80r / min), adopt 20V voltage, anodize by constant potential method for 1h, take out deionized water and ultrasonically clean, dry and set aside.

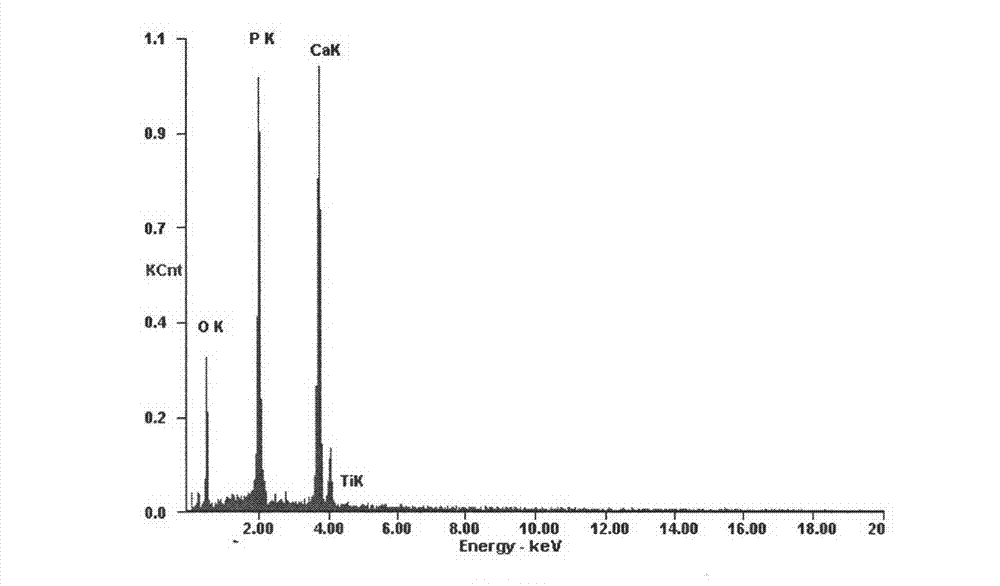

[0024] (3) Weigh 4.9592 g of calcium nitrate tetrahydrate and 1.4379 g of ammonium dihydrogen phosphate, and dissolve them in distilled water respectively. The abo...

Embodiment 2

[0029] The number of platinum electrodes in Example 1 can be more than two or ring electrodes as counter electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com