Preparation method of graphene/hydroxyapatite composite ceramic material

A technology of hydroxyapatite and composite ceramics, used in dental preparations, pharmaceutical formulations, dental prostheses, etc., can solve the problem of uneven distribution of graphene and hydroxyapatite, damage to the matrix and reinforcement phase, poor toughness of composite materials, etc. problems, to facilitate large-scale production, improve the brittleness problem, and achieve the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] As introduced in the background technology, there are some deficiencies in the preparation method of graphene / hydroxyapatite composite ceramic material in the prior art. In order to solve the above problems, the present invention proposes a graphene / hydroxyapatite composite ceramic material. The preparation method comprises the following steps:

[0033] The first step: respectively prepare Ca(NO 3 ) 2 4H 2O solution and (NH 4 ) 2 HPO 4 solution, the Ca(NO 3 ) 2 4H 2 The pH of the O solution was adjusted with ammonia water; the Ca(NO 3 ) 2 4H 2 O solution and (NH 4 ) 2 HPO 4 The solution is mixed and stirred well.

[0034] In some preferred technical solutions of the present invention, configured Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The substance concentration of the solution is 0.4-0.6mol / L, and the substance quantity ratio of calcium and phosphorus contained in the solution is 1:1.67. The concentration of this substance is used to make graphene o...

Embodiment 1

[0050] A preparation method of graphene / hydroxyapatite composite ceramic material, comprising the following steps:

[0051] (1) Preparation of graphene oxide

[0052] Pour 80ml of concentrated sulfuric acid, 9g of potassium permanganate and 2g of graphite powder refrigerated for 12 hours into the reaction kettle, let it stand at a low temperature at 0°C, and then put it into an oven. Pour the product into 320ml of deionized water for dilution, and add hydrogen peroxide and stir until the mixture turns yellowish brown or golden yellow. After standing still, the precipitate was washed by centrifugation and placed in a vacuum oven to dry to obtain graphene oxide (GO).

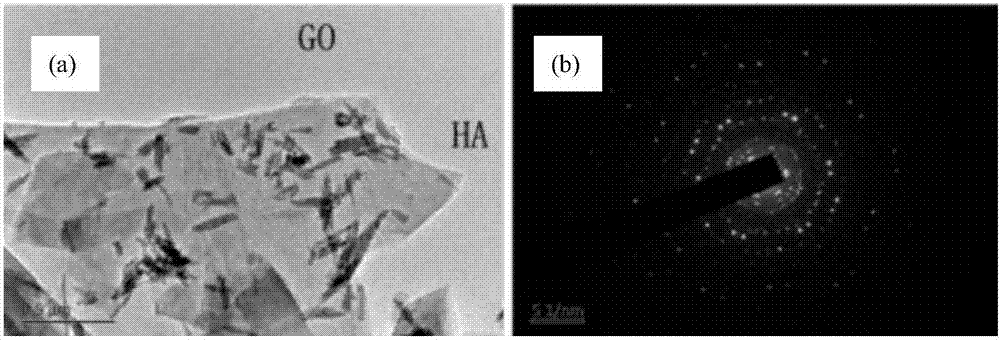

[0053] (2) Preparation of graphene / hydroxyapatite

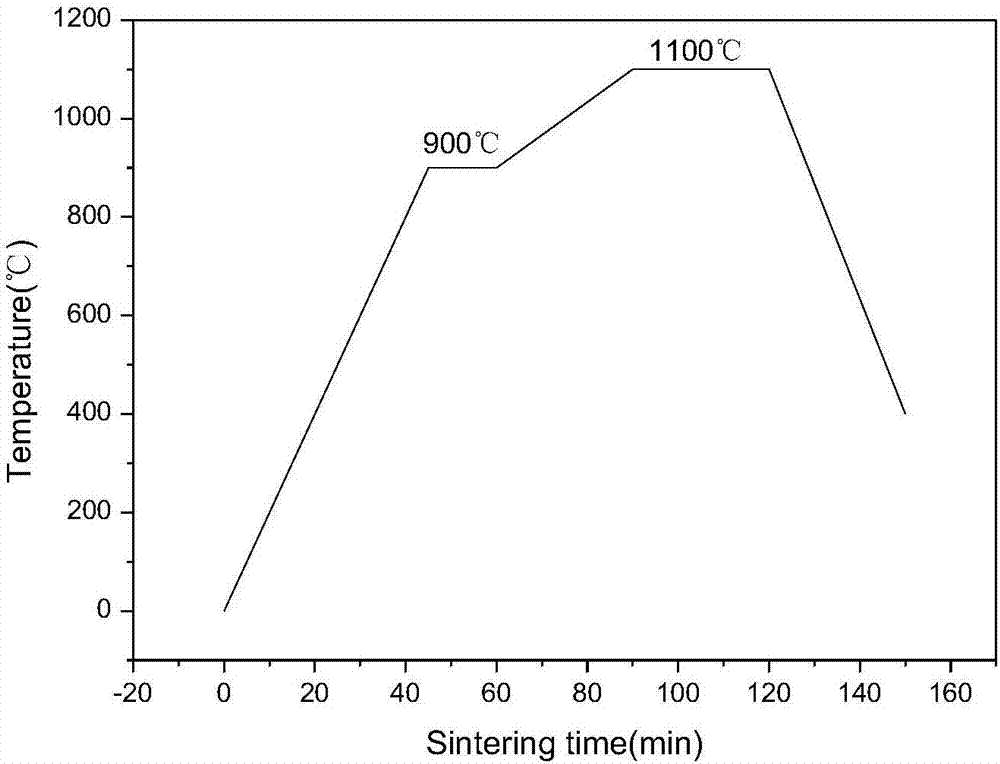

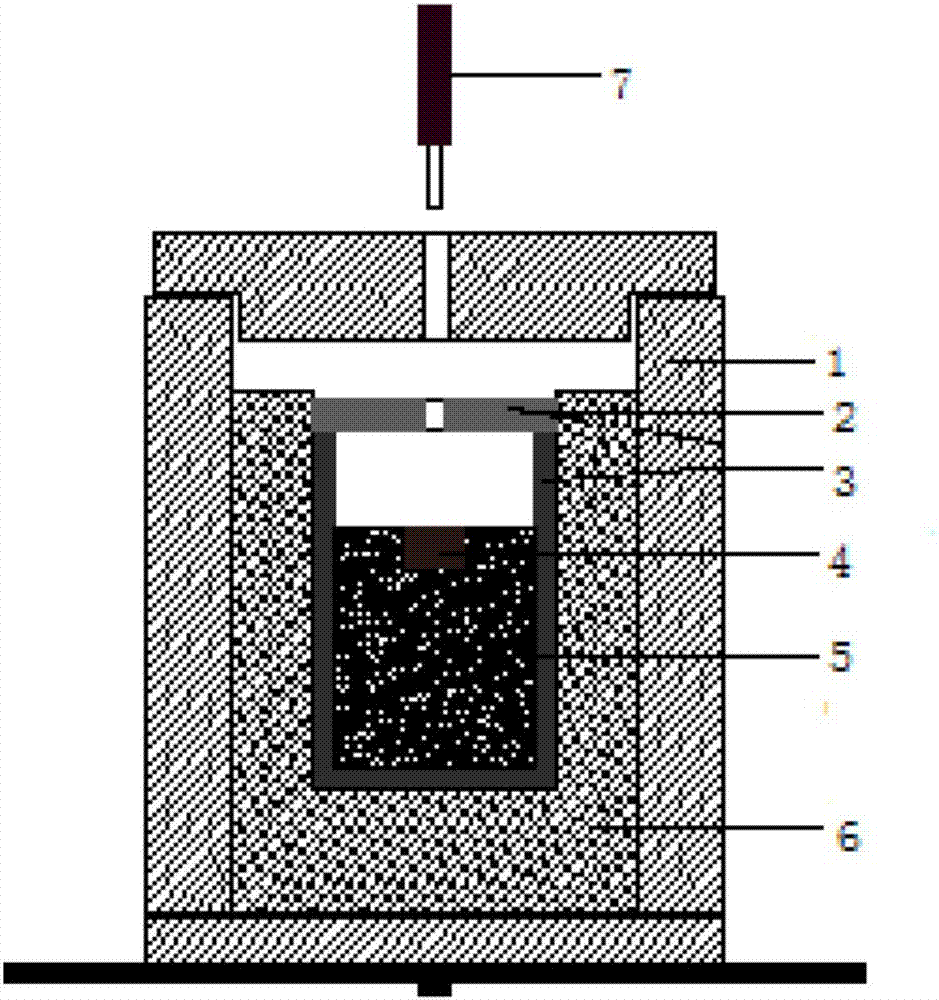

[0054] Weigh 29.52gCa(NO 3 ) 2 4H 2 O and 16.51g (NH 4 ) 2 HPO 4 Dissolve them in 250ml of deionized water to form a 0.5mol / L solution. Place in a constant temperature water bath and heat to constant temperature and adjust the pH value of calcium phospha...

Embodiment 2

[0060] A preparation method of graphene / hydroxyapatite composite ceramic material, comprising the following steps:

[0061] (1) Preparation of graphene oxide

[0062] Pour 80ml of concentrated sulfuric acid, 9g of potassium permanganate and 2g of graphite powder refrigerated for 12 hours into the reaction kettle, let it stand at a low temperature at 0°C, and then put it into an oven. Pour the product into 320ml of deionized water for dilution, and add hydrogen peroxide and stir until the mixture turns yellowish brown or golden yellow. After standing still, the precipitate was washed by centrifugation and placed in a vacuum oven to dry to obtain graphene oxide (GO).

[0063] (2) Preparation of graphene / hydroxyapatite

[0064] Weigh 59.04gCa(NO 3 ) 2 4H 2 O and 33.02g (NH 4 ) 2 HPO 4 Dissolve them in 250ml of deionized water to form a 0.5mol / L solution. Place in a constant temperature water bath and heat to constant temperature and adjust the pH value of calcium phospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness value | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com