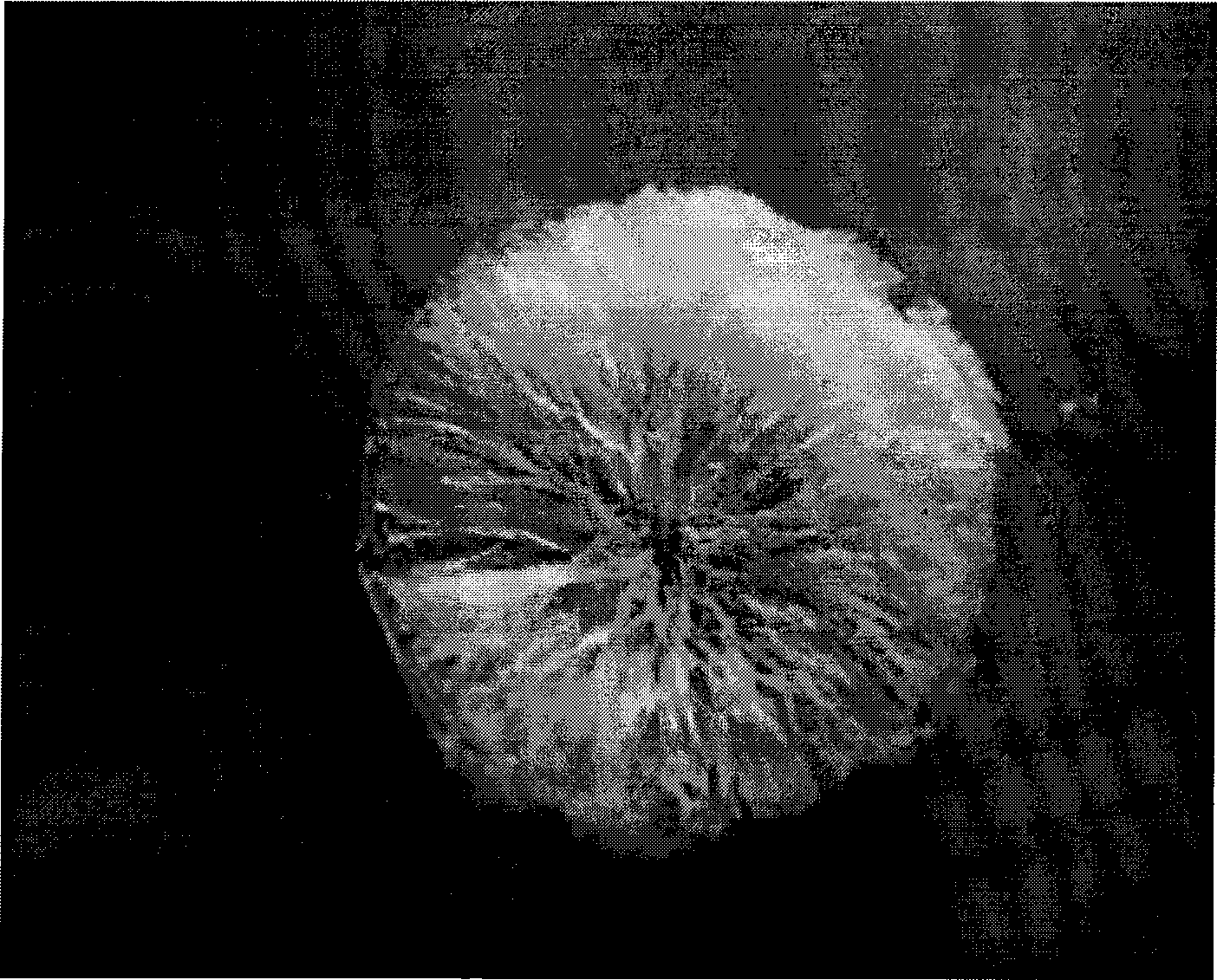

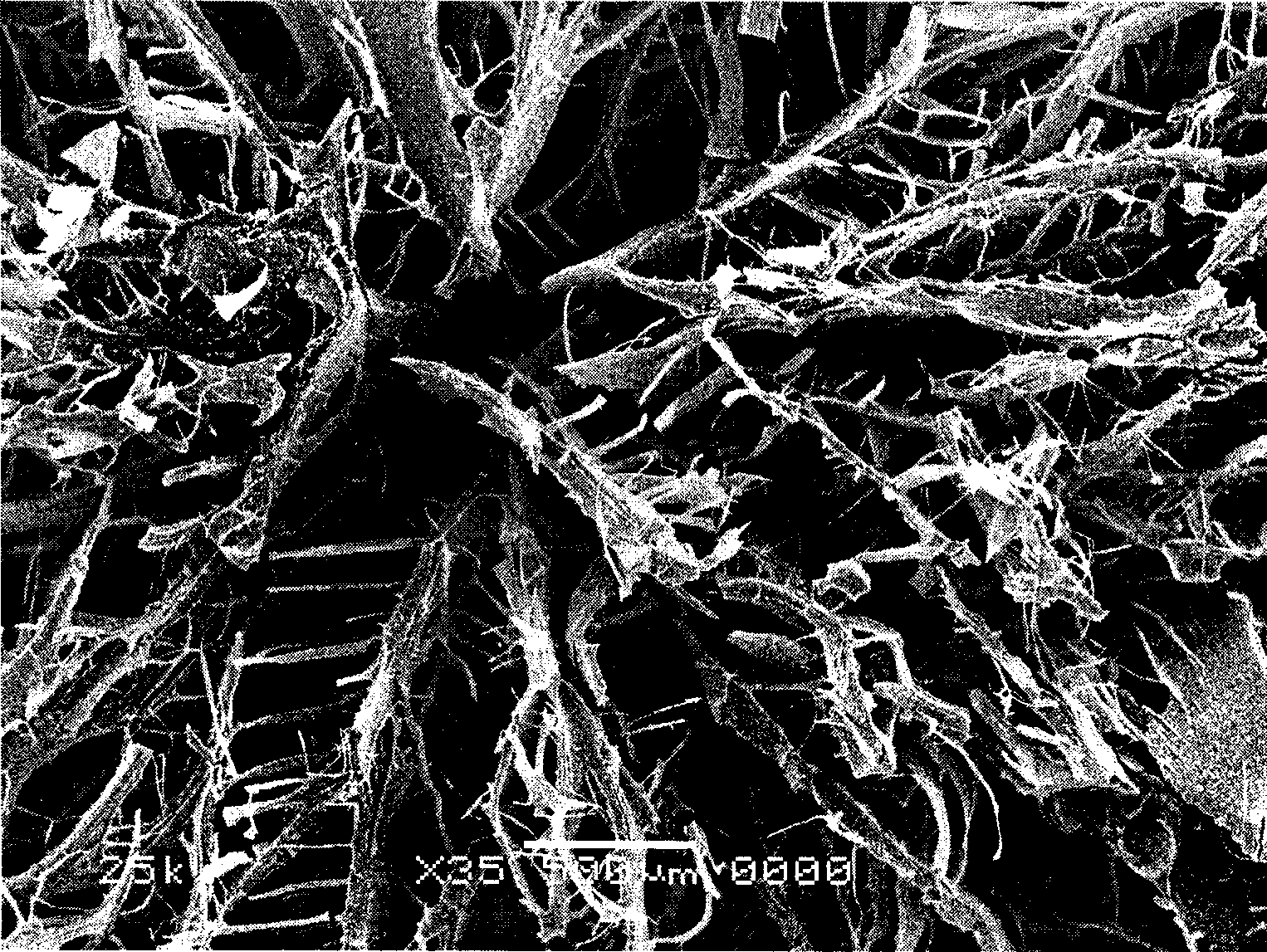

Method for preparing composite bone repair stent material containing chitosan and hydroxylapatite

A technology of hydroxyapatite and scaffold materials, which is applied in the fields of scaffolds, medical science, prostheses, etc., can solve the problems of uneven distribution of scaffolds, affecting the growth of osteoblasts, and the decline of mechanical properties of scaffolds, achieving strength adjustability, Excellent mechanical strength, the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Weigh CaCl according to the stoichiometric ratio 2 and KH 2 PO 4 Add it to 250ml of acetic acid solution with a volume fraction of 2%, and stir evenly to obtain a hydroxyapatite precursor solution;

[0022] 2) Add 10g chitosan to the hydroxyapatite precursor solution to make a chitosan and hydroxyapatite composite solution with a mass concentration of 4%, and the mass ratio of chitosan to hydroxyapatite is 100: 5. Stir vigorously to form a uniform mixed solution of chitosan and hydroxyapatite, and let it stand for defoaming;

[0023] 3) Take a small amount of mixed solution of chitosan and hydroxyapatite and evenly coat the surface of the mold, place the mold in 5% NaOH coagulating solution at room temperature to solidify to form a film, then mix chitosan and hydroxyl The mixed solution of apatite is injected into the mold, and then the mold is put into a NaOH coagulation solution with a mass fraction of 5%, solidified for 8 hours, and demolded to obtain a gel of ...

Embodiment 2

[0030] 1) Weigh Ca(NO 3 ) 2 and NaH 2 PO 4 Add it to 250ml of acetic acid solution with a volume fraction of 2%, and stir evenly to obtain a hydroxyapatite precursor solution;

[0031] 2) Add 10g chitosan to the hydroxyapatite precursor solution to make a chitosan and hydroxyapatite composite solution with a mass concentration of 4%, and the mass ratio of chitosan to hydroxyapatite is 100: 10. Stir vigorously to form a uniform mixed solution of chitosan and hydroxyapatite, and let it stand for defoaming;

[0032] 3) Take a small amount of mixed solution of chitosan and hydroxyapatite and evenly coat the surface of the mold, place the mold in 5% NaOH coagulating solution at room temperature to solidify to form a film, then mix chitosan and hydroxyl The mixed solution of apatite is injected into the mold, and then the mold is put into a NaOH coagulation solution with a mass fraction of 5%, solidified for 4 hours, and demolded to obtain a gel of chitosan and hydroxyapatite; ...

Embodiment 3

[0039] 1) Weigh CaCl according to the stoichiometric ratio 2 and K 2 HPO 4 Add it to 250ml of acetic acid solution with a volume fraction of 2%, and stir evenly to obtain a hydroxyapatite precursor solution;

[0040] 2) Add 10g chitosan to the hydroxyapatite precursor solution to make a chitosan and hydroxyapatite composite solution with a mass concentration of 4%, and the mass ratio of chitosan to hydroxyapatite is 100: 15. Stir vigorously to form a uniform mixed solution of chitosan and hydroxyapatite, and let it stand for defoaming;

[0041] 3) Take a small amount of mixed solution of chitosan and hydroxyapatite and evenly coat the surface of the mold, place the mold in 5% NaOH coagulating solution at room temperature to solidify to form a film, then mix chitosan and hydroxyl The mixed solution of apatite is injected into the mold, and then the mold is put into a NaOH coagulation solution with a mass fraction of 5%, solidified for 8 hours, and demolded to obtain a gel of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com