Flame-retardant microcrystalline cellulose/hydroxyapatite composite aerogel and preparation method thereof

A technology of hydroxyapatite and microcrystalline cellulose, which is applied in the fields of phosphorus compounds, chemical instruments and methods, colloid chemistry, etc., can solve problems such as no public reports on composite airgel research, and achieve excellent biocompatibility and Environmental friendliness, improved fire safety, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 5.904g of calcium nitrate [Ca(NO 3 ) 2 4H 2 O] was dissolved in 25mL deionized water, and weighed 1.725g of ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) was dissolved in 25mL deionized water, and the above two solutions were mixed and stirred evenly, wherein the molar ratio of Ca / P was 5:3; the pH of the mixed solution was adjusted to 10 with 25% ammonia water, and reacted in a 40°C water bath for 1h ; transfer the above solution to the reaction kettle, and react at 180°C for 16h; after the reaction, cool to room temperature, open the kettle, centrifuge the solution, wash 3 times with deionized water, the centrifugal speed is 6000r / min, and the time is 8min. Finally, it was dried in an oven at 70° C. for 24 hours, and the obtained product was hydroxyapatite nanorods. Weigh 2.5g of hydroxyapatite nanorods and disperse them in 22.5mL of water, the content of hydroxyapatite is 10%, and ultrasonically stir for 2h to prepare a uniformly dispersed hydroxyapatite ...

Embodiment 2

[0030] Weigh 7g of sodium hydroxide and 12g of urea and dissolve them in 81mL of deionized water, place the solution in a freezer at -12°C for 20 minutes, weigh 6g of microcrystalline cellulose and slowly add it to the above solution, and stir for 0.5h until complete Dissolved, transferred to a three-necked bottle equipped with a mechanical stirring device and placed in a low-temperature water tank at 0°C, slowly added 4 mL of epichlorohydrin dropwise, and mechanically stirred for 1 hour to obtain a microcrystalline cellulose solution.

[0031] The above solution was placed in a constant temperature drying oven at 50°C for 12 hours to prepare microcrystalline cellulose hydrogel; the above hydrogel was rinsed with water to pH = 7, put into a freezer at -56°C for 12 hours, and then placed in a Dry in a vacuum freeze dryer for 120 hours, and the obtained product is microcrystalline cellulose airgel.

Embodiment 3

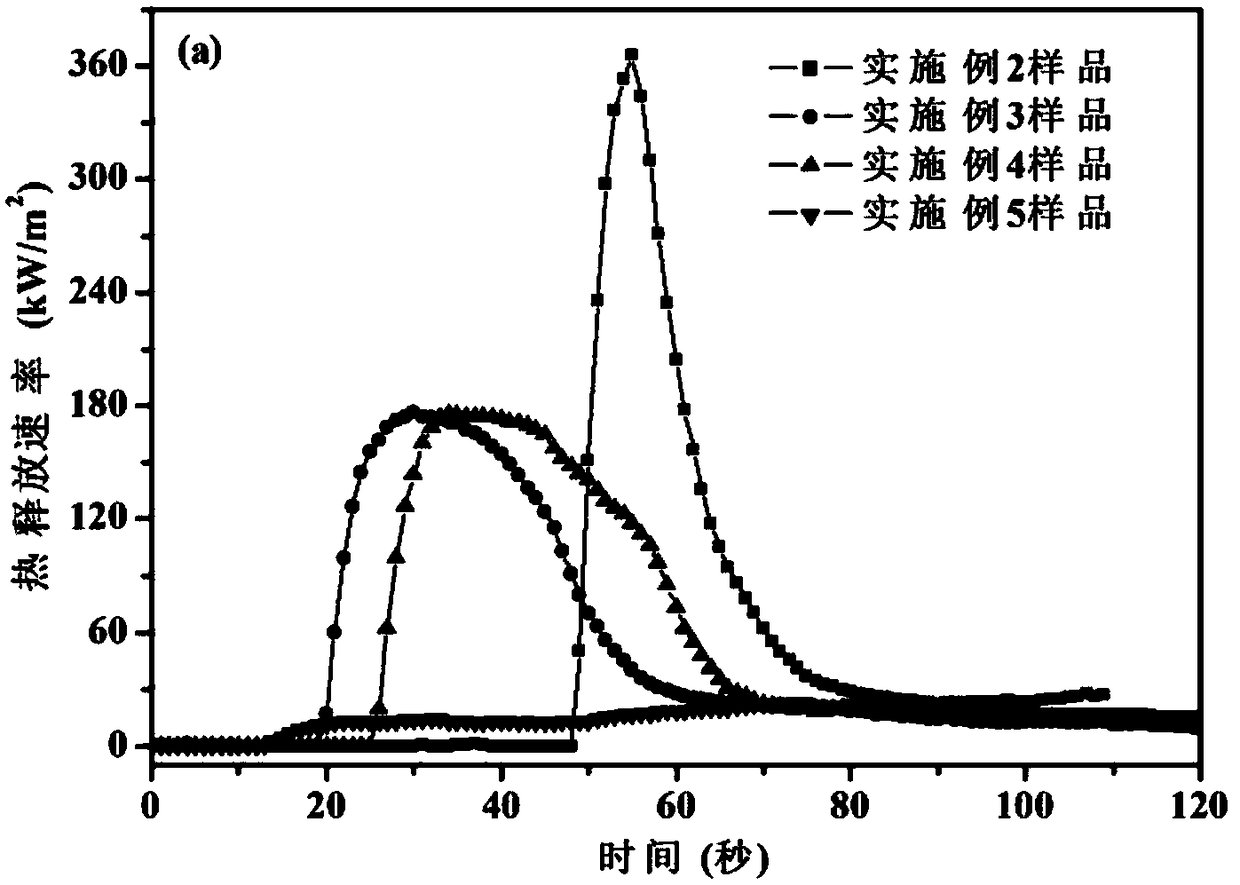

[0033]Weigh 25.4g of the microcrystalline cellulose solution prepared in Example 2 and 4.6g of the hydroxyapatite dispersion prepared in Example 1, mix the two and stir evenly, wherein the hydroxyapatite is mixed in microcrystalline cellulose / hydroxyphosphorus The content of the limestone composite airgel is 25%, and the microcrystalline cellulose / hydroxyapatite composite hydrogel is obtained by standing in a constant temperature drying oven at 50°C for 12 hours; the above hydrogel is rinsed with water until pH=7 , placed in a freezer at -56°C for 12 hours, and then dried in a vacuum freeze dryer for 96 hours. The resulting product is a flame-retardant microcrystalline cellulose / hydroxyapatite composite airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com