Polyvinyl alcohol/sodium alginate/hydroxyapatite composite fiber membrane as well as preparation method and application of polyvinyl alcohol/sodium alginate/hydroxyapatite composite fiber membrane

A hydroxyapatite and composite fiber membrane technology, which is used in spinning solution preparation, medical science, non-woven fabrics, etc. Limestone nanoparticles are easy to agglomerate and other problems to achieve the effect of improving the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a polyvinyl alcohol / sodium alginate / hydroxyapatite composite fiber membrane and a preparation method thereof, specifically as follows:

[0028] First, prepare a diammonium hydrogen phosphate solution with a concentration of 0.001-0.1mol / L and a calcium nitrate solution with a concentration of 0.00668-0.167mol / L, and quickly pour the diammonium hydrogen phosphate aqueous solution into the calcium nitrate aqueous solution according to the molar ratio of Ca / P=1.67 , adding ammonia water dropwise to the mixed solution to adjust the pH of the solution to 9-10, stirring evenly and then reacting at 80°C, centrifuging and washing with water several times to obtain a white precipitate of hydroxyapatite. Disperse the white precipitate of hydroxyapatite in deionized water, then add sodium alginate to ultrasonically mix and disperse to obtain a suspension of hydroxyapatite stabilized by sodium alginate, wherein the concentration of sodium alginate is 0.04-0.15...

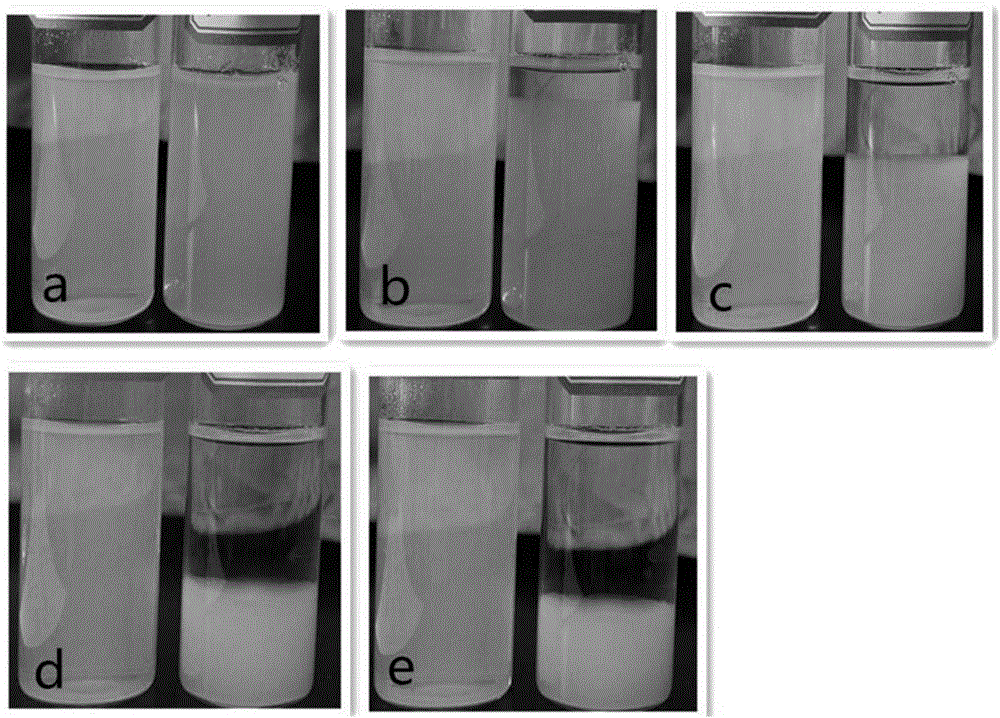

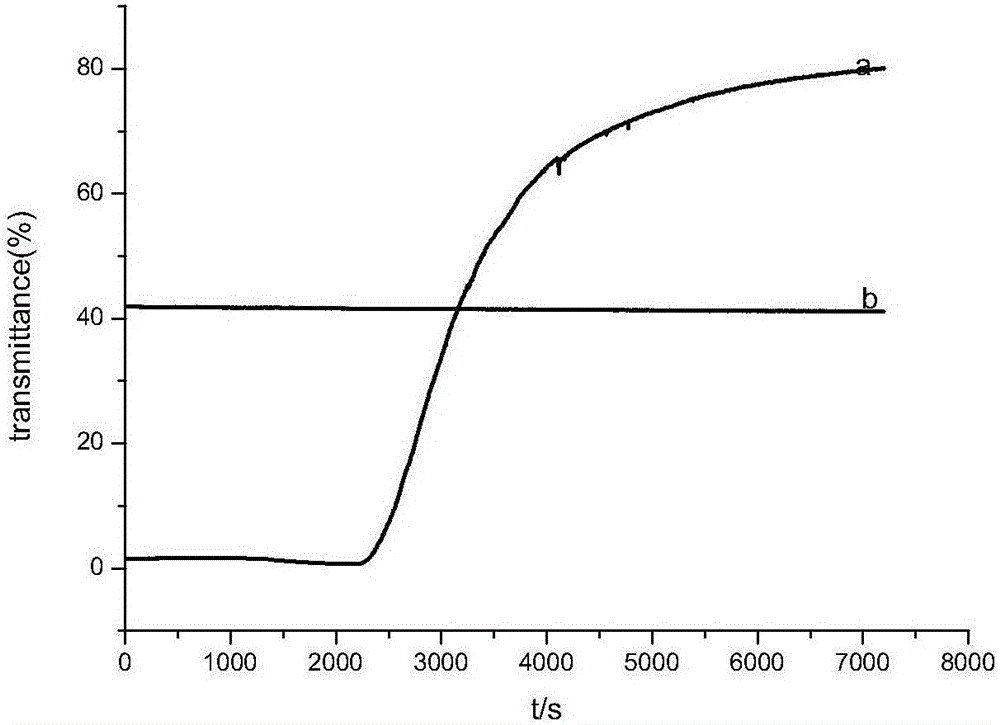

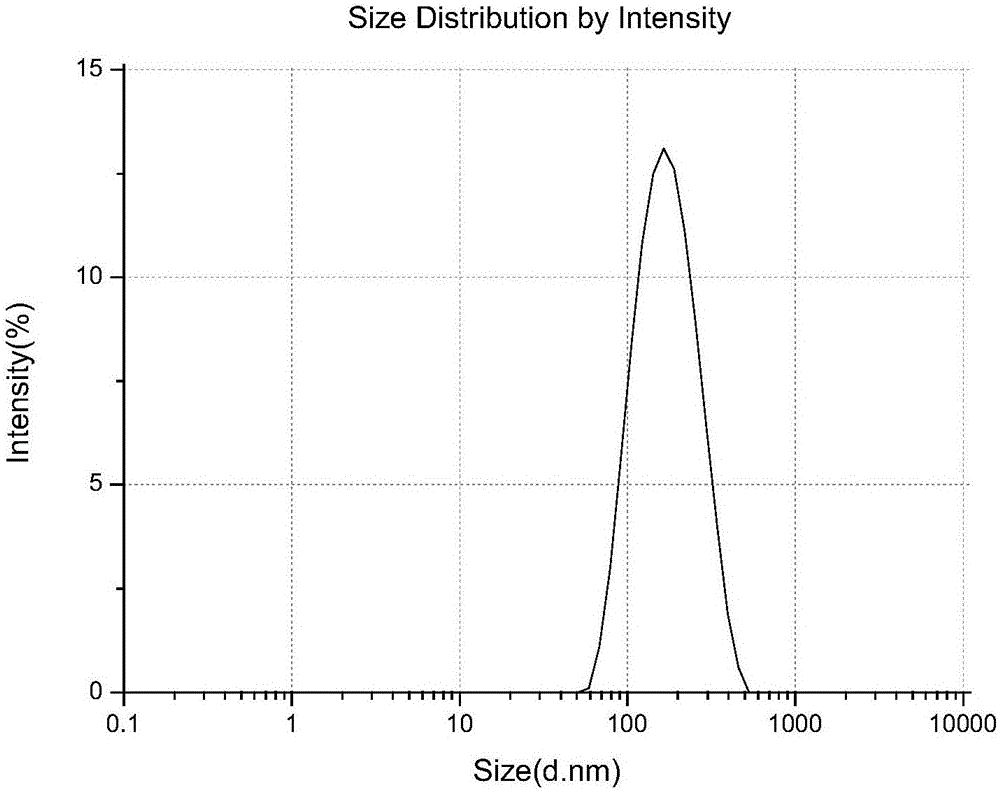

Embodiment 1

[0032]1) First, prepare an aqueous solution of calcium nitrate with a concentration of 0.0334mol / L and an aqueous solution of diammonium hydrogen phosphate with a concentration of 0.02mol / L, respectively. According to the molar ratio of Ca / P=1.67, quickly pour 20mL diammonium hydrogen phosphate aqueous solution into 20mL calcium nitrate aqueous solution, add ammonia water dropwise to the mixed solution, control the pH of the solution to 9-10, stir and mix evenly. After maintaining the reaction temperature at 80° C. for 1 h, centrifugation was repeated three times with deionized water to obtain a white precipitate. The white precipitate was redispersed in 40 mL of deionized water to obtain a hydroxyapatite dispersion with a concentration of 1.67 mg / mL, and 20 mL of this dispersion was taken for use. Take 10mL of deionized water and 0.1g of sodium alginate to prepare a sodium alginate solution with a mass fraction of 1%, add 0.08mL of sodium alginate solution to the above 20mL d...

Embodiment 2

[0039] 1) First, prepare an aqueous solution of calcium nitrate with a concentration of 0.0334mol / L and an aqueous solution of diammonium hydrogen phosphate with a concentration of 0.02mol / L, respectively. According to the molar ratio of Ca / P=1.67, quickly pour 20mL diammonium hydrogen phosphate aqueous solution into 20mL calcium nitrate aqueous solution, add ammonia water dropwise to the mixed solution, control the pH of the solution to 9-10, stir and mix evenly. After maintaining the reaction temperature at 80° C. for 1 h, centrifugation was repeated three times with deionized water to obtain a white precipitate. The white precipitate was redispersed in 40 mL of deionized water to obtain a hydroxyapatite dispersion with a concentration of 1.67 mg / mL, and 20 mL of this dispersion was taken for use. Take 10mL of deionized water and 0.1g of sodium alginate to prepare a sodium alginate solution with a mass fraction of 1%, add 0.08mL of sodium alginate solution to the above 20mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com