Hydroxyapatite nano-complex particle, preparation and uses thereof

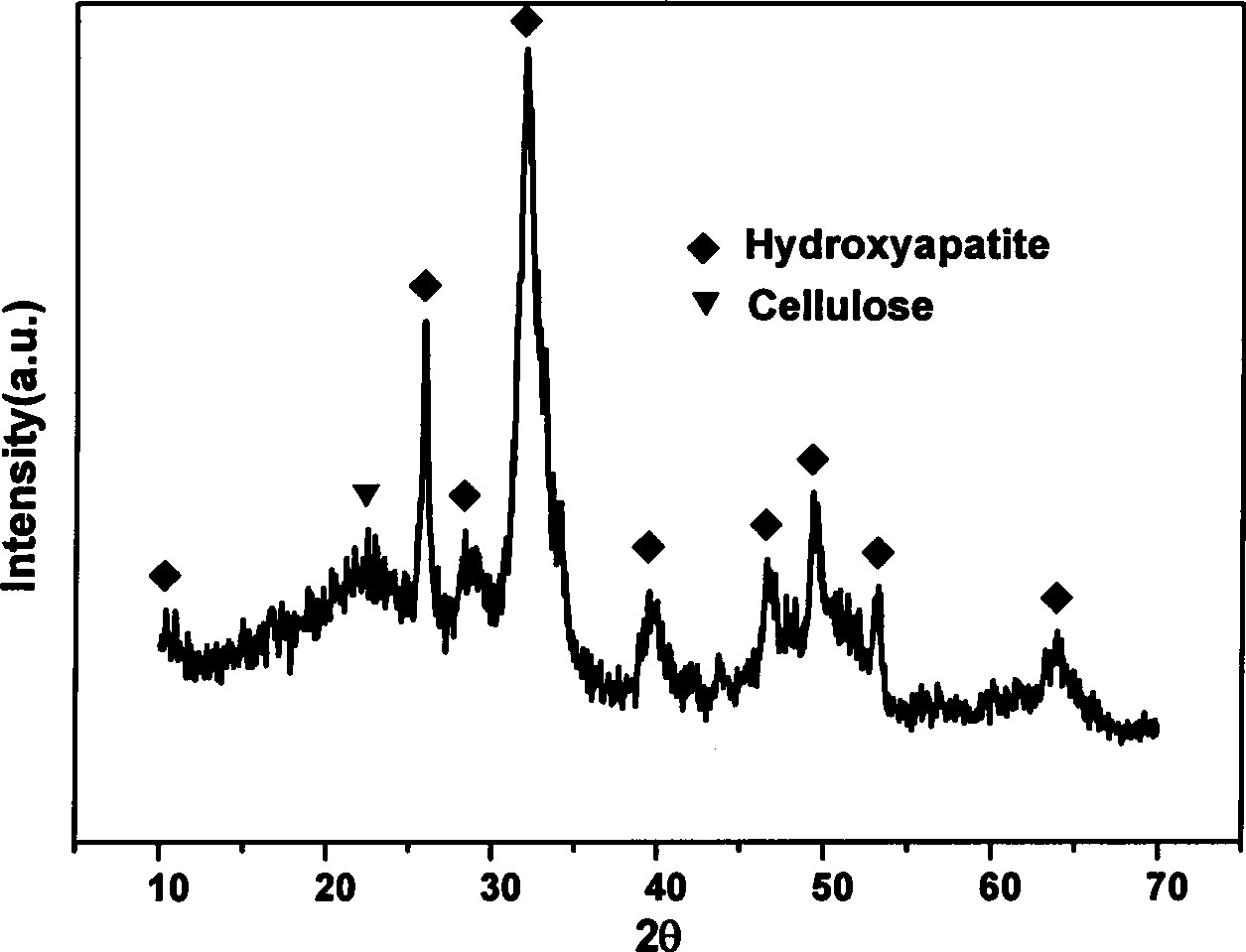

A nano-composite particle, hydroxyapatite technology, applied in phosphorus compounds, chemical instruments and methods, fluorescence/phosphorescence, etc., can solve problems such as poor dispersion stability, and achieve the effects of low cost, environmental friendliness, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

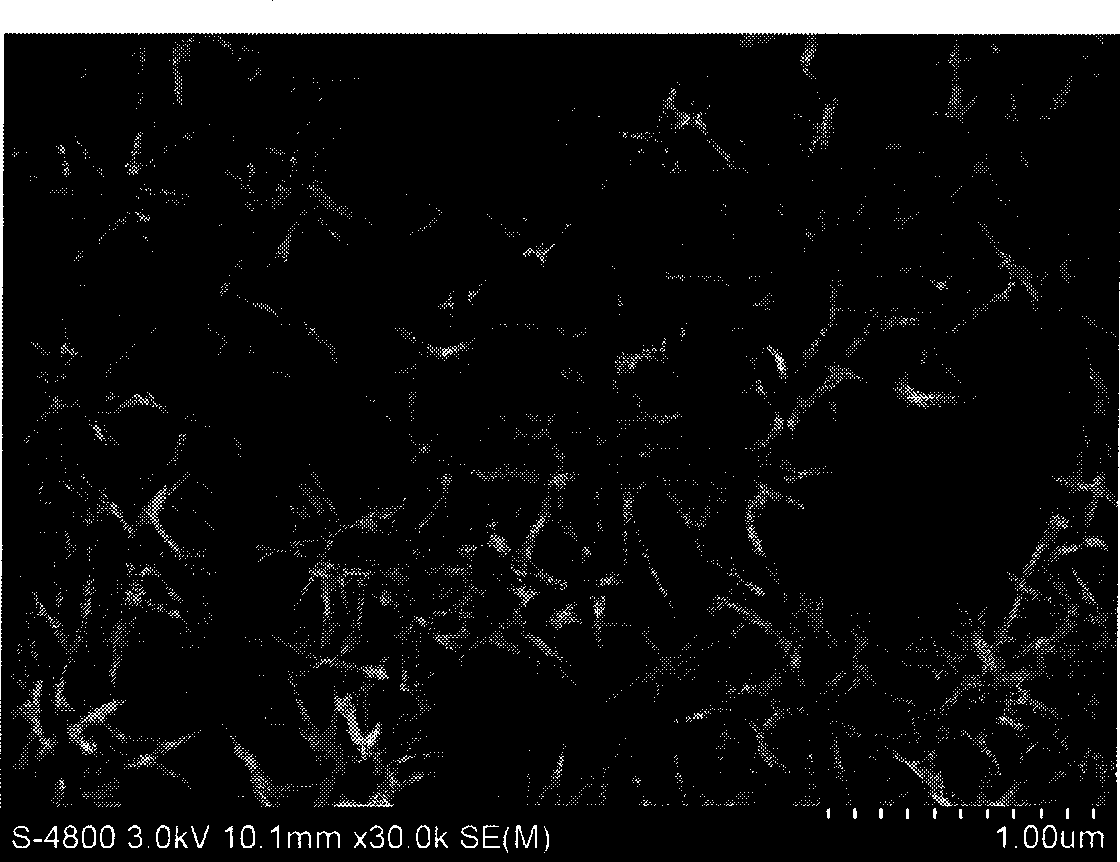

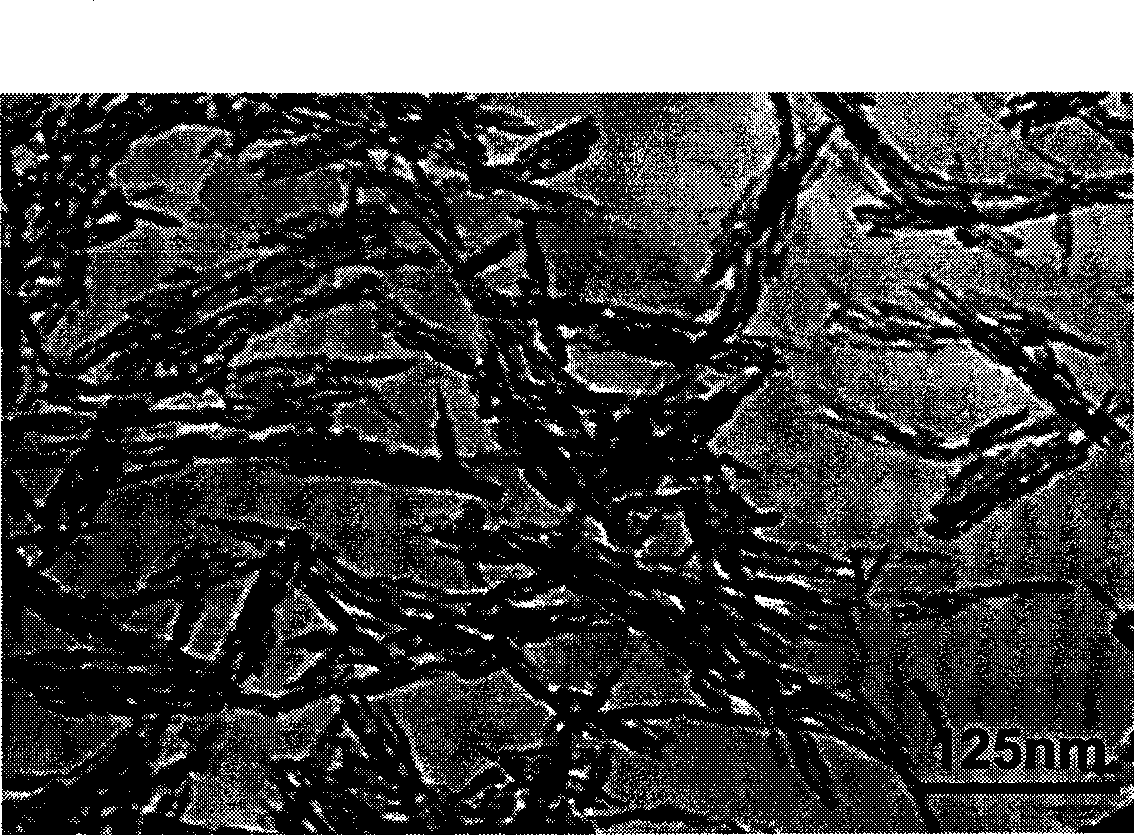

[0032] In this embodiment, the process steps for preparing hydroxyapatite nanocomposite particles are as follows:

[0033] (1) Dissolution of cellulose

[0034] Take 0.05g of 500-mesh moso bamboo cellulose powder and add it to 12.50mL of NaI-NaNO with a concentration of 1.0mol / L 3 -in NaBr aqueous solution (the concentration of three kinds of sodium salts in the solution is 1.0mol / L), heated to 60°C under magnetic stirring (stirring speed is 400 rev / min) and keeps the temperature at 60°C to make Phyllostachys pubescens The cellulose powder is completely dissolved (about 6 hours) to form a cellulose-salt homogeneous aqueous solution;

[0035] (2) Reaction synthesis

[0036] After the bamboo cellulose-salt solution prepared in step (1) was cooled to room temperature, under stirring at a speed of 400 rpm, Ca(NO 3 )2 4H 2 O aqueous solution, Na with a concentration of 0.05mol / L 2 HPO 4 12H 2 Each 25mL of O aqueous solution, the Ca / P=1.2:1 of reaction system;

[0037] Then,...

Embodiment 2

[0042] In this embodiment, the process steps for preparing hydroxyapatite nanocomposite particles are as follows:

[0043] (1) Dissolution of cellulose

[0044] Get 0.03kg400 mesh pine wood cellulose powder, join 45L concentration and be the ZnCl of 5mol / L 2 In the aqueous solution, heat to 100°C under magnetic stirring (stirring speed is 400 rpm) and keep the temperature at 100°C to completely dissolve the pine wood cellulose powder (about 2 hours), forming a cellulose-salt homogeneous aqueous solution;

[0045] (2) Reaction synthesis

[0046] After the pine wood cellulose-salt solution prepared in step (1) was cooled to room temperature, under stirring at a speed of 400 rpm, Ca(NO 3 ) 2 4H 2 O aqueous solution, concentration 0.25mol / L (NH 4 ) 2 HPO 4 2H 2 Each 2.5L of O aqueous solution, the Ca / P=2.0:1 of reaction system;

[0047] Subsequently, adjust the pH value of the reaction system with ammonia water with a concentration of 1.0 mol / L and HCl with a concentratio...

Embodiment 3

[0052] In this embodiment, the process steps for preparing hydroxyapatite nanocomposite particles are as follows:

[0053] (1) Dissolution of cellulose

[0054] Take 0.10g 300 mesh defatted cotton cellulose powder, add to 50mL ZnCl with a concentration of 2mol / L 2 -Mg(NO 3 ) 2 -MgCl 2 In the aqueous solution (the concentration of the substance of the three metal salts is 2mol / L), heat to 80°C under magnetic stirring (stirring speed is 400 rpm) and keep the temperature at 80°C to make the degreased cotton cellulose powder completely Dissolving (about 4 hours), forming a homogeneous aqueous solution of cellulose-salt;

[0055] (2) Reaction synthesis

[0056] After the defatted cotton cellulose-salt solution prepared in step (1) was cooled to room temperature, under stirring at a speed of 400 rpm, Ca(NO 3 ) 2 4H 2 O aqueous solution, NaH with a concentration of 0.6mol / L 2 PO 4 2H 2 Each 15mL of O aqueous solution, the Ca / P=1.67:1 of reaction system;

[0057] Then, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com